What Elements Are Used in Batteries? A Complete Guide to Battery

Feb 28, 2025 · As battery technology advances, new metal elements used in rechargeable batteries are continuously being explored to make devices more energy-efficient,

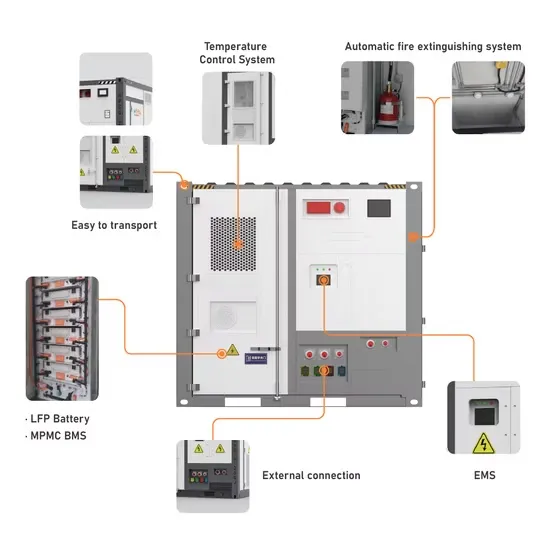

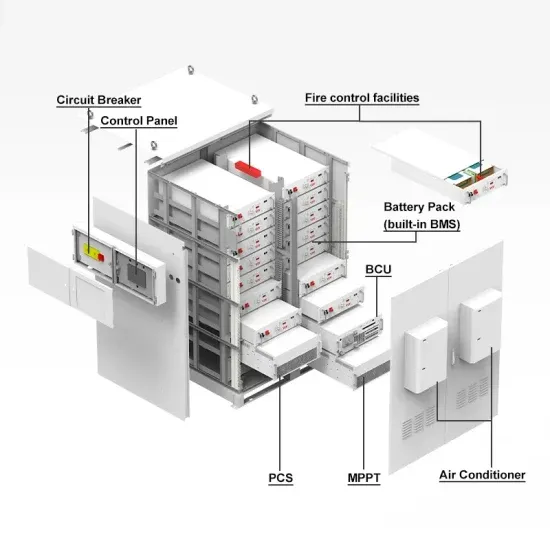

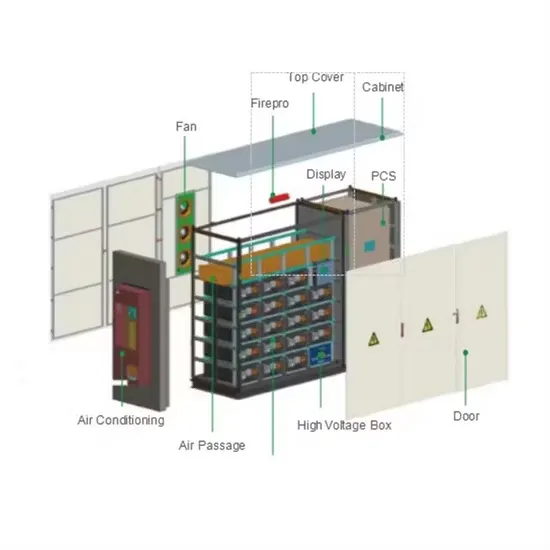

Battery Energy Storage Cabinet Composition: The Nuts,

Nov 13, 2022 · Enter battery energy storage cabinets, the backstage crew making sure your lights stay on. These metallic marvels are essentially giant power banks for cities, factories, and

How much energy can be stored in a cabinet? | NenPower

Feb 1, 2024 · The amount of energy that can be stored in a cabinet varies widely based on its type and design. 1. Electric cabinets, such as battery storage units, can hold energy ranging

What ingredients does the new energy battery contain

What are car batteries made of? Today, most batteries are made of a lithium-ion construction, however other common battery types include nickel-metal hydride and lithium-iron phosphate.

What elements do energy storage batteries

Jun 18, 2024 · Energy storage batteries primarily consist of 1. Active materials, 2. Electrolytes, 3. Current collectors, 4. Separators, which are essential for their

Does the Energy Storage Cabinet Battery Cell Contain

Spoiler alert – about 92% of new grid-scale energy storage systems deployed in 2023 used lithium-based battery cells. But here''s the kicker: not all that glitters is lithium.

IBM Discovers Battery That Doesn''t Use Heavy

Dec 21, 2019 · While electric vehicles are often lauded for being zero-emission alternatives to gas-powered cars, the lithium-ion batteries used to power them

FACT SHEET BATTERY & ENERGY METALS

Dec 13, 2023 · Overview ls required for the energy sector. Intertek Minerals defines a battery and energy metal as any metal that is necessary for the transition towards net zero through the

Names of various components of new energy battery cabinet

The most common NEMA rating for solar and stationary battery boxes is NEMA 3R and all Fabricated Metals battery and energy storage cabinets and enclosures are designed to meet

What components does the energy storage cabinet consist of?

May 21, 2024 · The energy storage cabinet is a sophisticated assembly designed to optimize the utilization and management of energy. 1. Essential Components Include electrodes, battery

What are the types of new energy batteries

May 5, 2021 · The traditional lead-acid battery, nickel-cadmium battery, and nickel-hydrogen battery technology are mature, but there are big problems in using lithium batteries as power

How much aluminum content does new energy battery contain

Aluminium-ion batteries are a class ofin whichions serve as . Aluminium can exchange three electrons per ion. This means that insertion of one Alis equivalent to three Liions. Thus, since

What Metals Are In A Car Battery? Uncovered | CarsBibles

Mar 4, 2025 · Car batteries contain valuable metals that can be recovered and reused through recycling. This process not only reduces the environmental impact of battery disposal but also

Revving Up the Future: Exploring the Essential

Nov 14, 2023 · These metals are essential in creating the chemical reactions that produce electrical energy, allowing for the vehicle to run without gasoline.

How much does the energy storage battery

Jan 22, 2024 · The price of energy storage battery cabinets can vary significantly depending on various factors. 1. General cost range: The costs typically range

How much cobalt does the battery energy storage material contain

Feb 27, 2024 · 1. Cobalt content in battery energy storage materials varies significantly based on chemistry and application. This aspect can be articulated through three core focal points: 1.

Does the new energy battery contain high levels of

As a transition metal,Ni provides high energy capacity,along with high conductivity and energy density,which improves the quality of the lithium-ion battery performance (Nuhu et al.,2023).

6 FAQs about [What metals does the new energy battery cabinet contain ]

What are the different types of battery energy storage systems?

The different BESS types include lithium-ion, lead-acid, nickel-cadmium, and flow batteries, each varying in energy density, cycle life, and suitability for specific applications.

How many batteries are in a battery energy storage system?

Battery energy storage systems (BESS) store energy from different sources in a rechargeable battery. The total number of batteries depends on several factors: the number of cells per module, the modules per rack, and the racks connected in series. For instance, a BESS can consist of 5,032 modules containing over 100,000 lithium-ion batteries.

Which metal is used in a Bess battery?

Manganese and aluminum are often used in the cathodes of these batteries, contributing to improved durability and safety. Lead is a crucial metal in lead-acid batteries, a traditional but widely used BESS technology, especially in applications where cost is critical.

What are the different types of Bess batteries?

The different BESS types include lithium-ion, lead-acid, nickel-cadmium, and flow batteries, each varying in energy density, cycle life, and suitability for specific applications. Lithium-ion Batteries: The most widely used type of BESS, lithium-ion batteries are known for their high energy density, long cycle life, and efficiency.

What metals go into a Bess system?

Each component is optimized for energy efficiency, safety, and scalability. What metals go into BESS systems? BESS components typically include metals like lithium, cobalt, nickel, manganese, and sometimes iron and graphite, each chosen to enhance energy density, stability, and battery performance.

What are lithium ion batteries?

Lithium-ion batteries also incorporate cobalt and nickel, which help enhance the battery’s energy capacity and stability. Manganese and aluminum are often used in the cathodes of these batteries, contributing to improved durability and safety.

Update Information

- What are the new energy battery cabinet cloth manufacturers

- What is the brand of new energy battery cabinet

- What is the power of the new energy battery cabinet

- Does the new energy battery cabinet measure voltage

- What batteries are included in the photovoltaic energy storage battery cabinet

- How to buy a new energy battery cabinet cost-effectively

- New Energy Battery Cabinet Cooling

- What type of battery is the energy storage cabinet battery called

- What does the outdoor energy storage power battery cabinet include

- New Energy Backup Battery Cabinet

- Repair of new energy battery cabinet in Port Louis

- New Energy Battery Cabinet Production Process

- New Energy Battery Cabinet Pre-charge Resistance

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.