Thermal performance evaluation of new energy vehicle pre-charge

Aug 1, 2023 · Abstract Thermal management of new energy vehicles is a crucial factor restricting their development. For the possible short-circuit problem of capacitors in the motor controller

What does pre-charge resistance mean? The role of pre-charge resistance

The pre-charge resistor is a circuit component used in new energy vehicles. It is a circuit composed of resistors, capacitors and relays. Its main function is to pre-charge the high

Advanced Materials for High-Performance Pre-Charge

Feb 20, 2025 · This blog post discusses the advanced materials used in high-performance pre-charge resistors for electric vehicles (EVs). These materials are essential for ensuring safe

Cabinet Regenerative Battery Pack Testing System Charge

Mar 5, 2025 · Product Description I.hondian introductionBattery charging and discharging tester is a special instrument for testing lithium battery pack, lead-acid battery pack, portable mobile

Lithium Battery Charging Cabinet: The Essential Guide to

May 9, 2025 · The widespread use of lithium-ion batteries across various industries and applications—ranging from power tools to electric vehicles—has led to increasing concern

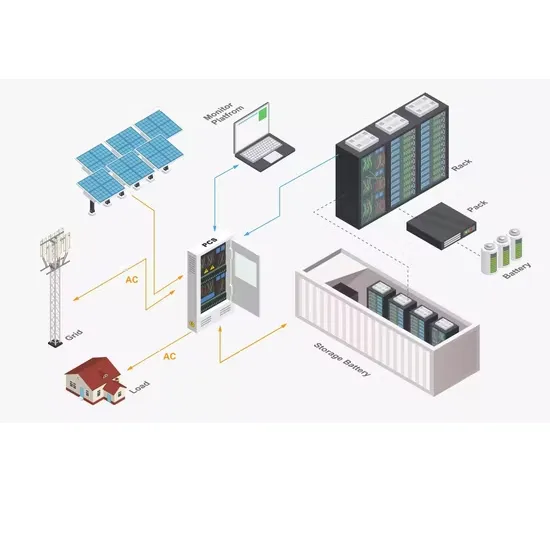

Energy storage container pre-charge resistance standard

Components of EnerC liquid-cooled energy storage container. Battery Racks, BMS, TMS, FSS, and Auxiliary distribution system The actual power consumption is depend on the ambient

Xiaoyi New Energy Battery Energy Storage Cabinet

Aug 21, 2021 · Against the backdrop of swift and significant cost reductions,the use of battery energy storage in power systems is increasing. Not that energy storage is a new phenomenon:

Energy storage battery pre-charge resistance

Lithium-based rechargeable batteries, including lithium-ion batteries (LIBs) and lithium-metal based batteries (LMBs), are a key technology for clean energy storage systems to alleviate the

Pre-Charge Circuits Lead to Safer EVs

Jan 5, 2024 · Pre-charging of electric-vehicle power circuits is one of the best ways to ensure component longevity and reliability while also establishing safer operations.

The Role of Precharge and Discharge Resistors in Safety

Apr 15, 2025 · One notable innovation involves the elimination of the costly power resistor and its associated contactor, a development that significantly reduces heat dissipation and may

Comprehensive_Analysis_of_Pre_Charge_Sequence_inAutomotive_Battery

Jan 25, 2020 · Upon completion of the pre-charging sequence, the pre-charge resistor is switched out of the power supply circuit and returns to a low impedance power source for normal mode.

Energy storage high voltage cabinet pre-charging circuit

What is a pre-charge circuit? Applications and Benefits Pre-charge circuits are often used in electric vehicles (EVs) such as battery management systems, onboard chargers, and in

Energy storage container pre-charge resistance standard

The heat release capacity and thermal runaway degree increase with the state of charge of the battery. this paper investigated a 50-ft standard energy storage system (ESS) container and

Why Energy Storage Container Pre-Charge Resistance Is

But here''s the dirty little secret: your pre-charge resistance works harder than a caffeine-fueled engineer during blackout season. This component quietly prevents catastrophic failures when

Update Information

- New energy battery cabinet wiring detection

- New energy storage solar photovoltaic battery cabinet

- New energy battery cabinet cell voltage is low

- Georgetown New Energy Telecommunication Power Supply Battery Cabinet Factory

- Belgrade Customized New Energy Battery Cabinet

- Nassau New Energy Battery Cabinet

- New energy endurance plus battery cabinet

- New Energy 18 3 Battery Cabinet Price

- New Energy Communication High Voltage Battery Cabinet

- New Energy Battery Cabinet Cooling Method

- Basseterre new energy battery cabinet replacement

- There are several types of batteries in the new energy battery cabinet

- Energy storage cabinet battery new energy

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.