Novel active and passive balancing method-based battery management

Oct 20, 2021 · In this study, a novel battery management system (BMS) circuit topology based on passive and active balancing methods was created and implemented for battery-based systems.

A novel active cell balancing topology for serially connected Li

Aug 10, 2024 · Abstract In a Battery Management System (BMS), cell balancing plays an essential role in mitigating inconsistencies of state of charge (SoCs) in lithium-ion (Li-ion) cells

Active cell balancing for electric vehicle battery

Jun 1, 2020 · In Li-ion batteries, voltage differences always exist between cells due to charging and discharging process, therefore a battery management

c-BMS24X™ Battery Management System (BMS)

5 days ago · The c-BMS24X offers robust battery management in a compact footprint of 150 x 70 mm, for up to 24 cells in series and 6 temperature sensors. Built on the market-proven

Passive Balancing vs Active Balancing in Lithium Batteries

Jun 19, 2025 · Compare Passive Balancing vs Active Balancing in lithium batteries. Learn how each method impacts efficiency, cost, and application suitability.

How To Balance A Lithium Batteries: Top and

Oct 3, 2022 · A balanced battery pack is critical to getting the most capacity out of your pack, read along to learn how to top and bottom balance a lithium battery

Active balancing vs. Passive balancing in Battery

Nov 18, 2024 · Active balancing and passive balancing are two methods used in battery management systems (BMS) to ensure that all cells within a battery

A critical review of battery cell balancing techniques, optimal

Jun 1, 2024 · Considering the significant contribution of cell balancing in battery management system (BMS), this study provides a detailed overview of cell balancing methods and

Design and Performance Analysis of Active and Passive

Nov 5, 2023 · Abstract: Electric Vehicles (EV) are growing areas of research since the demand for clean transportation is ever-increasing. Batteries form an integral part of EVs. Battery

Update Information

- Lithium battery BMS active balancing

- Cape Town lithium battery bms company

- Brunei power lithium battery bms solution

- ApiA lithium battery bms function

- Lusaka lithium battery bms system

- Italian lithium battery bms price

- Australia s professional lithium battery bms management system

- Sukhumi lithium battery bms price

- Angola lithium battery bms price

- Sarajevo lithium iron phosphate battery bms wholesale

- Conakry lithium battery bms manufacturer

- Make lithium battery BMS

- Croatia energy storage lithium battery bms module

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

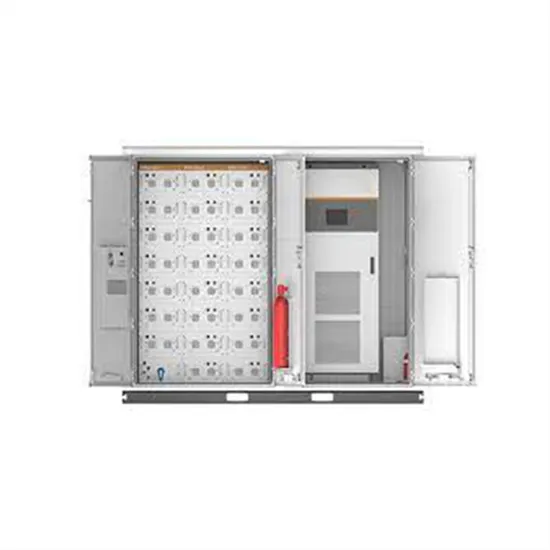

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.