INTRODUCTION TO MULTILEVEL INVERTERS

Oct 29, 2022 · Static power converters that converts DC voltages and currents to AC waveforms are usually known as inverters Converts DC to AC with a fundamental component with

MIT Open Access Articles A High Frequency Inverter for

Oct 1, 2022 · perating at high frequency (HF, 3- and efficiency under rapidly-varying loads. Eliminating the 30MHz) are important to numerous industrial and commercial applicat.

Comparison between two levels and multi-level (NPC and Cascad) inverters

Jan 1, 2022 · In this paper, a comparative study of multilevel inverters is carried out. Different topologies of inverters have been studied: two-level inverters, Neutral-Point clamped inverter

Inversion Methods Explained: High Frequency vs Low Frequency

4 days ago · These inverters are feature rich to include the optional ability to hardwire additional external GFCI outlets, input of multiple DC voltages, provide regulated dual output voltages

A comprehensive review of multi-level inverters, modulation,

Jan 3, 2025 · Conventional two-level inverters have many drawbacks, including higher THD, significant switching losses, and high voltage stress on semiconductor switches within inverter.

VFD vs. Inverters: Key Differences Explained

Aug 29, 2024 · Explore the key differences between Variable Frequency Drives (VFDs) and inverters in aircraft, focusing on their roles in controlling and optimizing power systems. To

High-Frequency vs. Low-Frequency Inverters

Inverters are crucial components in solar power systems, uninterruptible power supplies (UPS), and other electrical systems. Their job is to convert DC (direct current) power into AC

A comparative study of different multilevel inverters

Apr 29, 2017 · The problem is resolved by means of multilevel inverters (MLIs) which utilize lower switching frequencies and give high voltages with improved total harmonic distortion (THD)

Multi-Level Inverters: A Comparative Guide to NPC, FCI, and

Jul 27, 2025 · In power electronics, the standard two-level Voltage Source Inverter (VSI) has been the workhorse for decades. It''s simple, robust, and cost-effective for a wide range of low

Everything You Need to Know About the Split Phase Inverter

Mar 13, 2025 · Get to know about a split phase inverter; discover the fundamentals of a split phase inverter including its benefits, operations, and applications!

Discover the Power and Efficiency of Jupiter Inverters for

1 day ago · Solar inverters like Jupiter inverters are expected to incorporate eco-friendly manufacturing processes and recyclable components. As the demand for off-grid power

[Solved] a indicate the different voltage levels around the

(a), indicate the different voltage levels around the network. Explain the reasons why a range of voltages are used such as: · 15 to 25 kV at the generators · up to 400 kV for transmission · the

Multiple Inverters in Parallel: PV setup?

Jul 10, 2020 · When using 2 three-phase inverters in parallel, each with 2 build-in MPPT''s per inverter (so 4 in total), and all connected to one battery bank, will it make any difference how

Inverters, Types and Voltages

Dec 31, 2024 · Less robust when handling high surge loads compared to low-frequency inverters. Best Applications for High Frequency Inverters: Residential solar systems with average energy

Do you Need a Three Phase PV Inverter

Mar 31, 2023 · A three phase PV inverter is a good option for homes and businesses with high power loads. It converts DC to AC power efficiently and allows for high loads and greater

Frequency and Voltage Control Schemes for Three-Phase

Jan 1, 2020 · Grid-forming inverters play an important role in supporting power systems with low rotational inertia. Their frequency and voltage control policies must guarantee a synchronised

Paper Title (use style: paper title)

Nov 22, 2024 · Multi-level inverters (MLIs) offer a promising solution by providing multiple voltage levels, which results in improved output waveforms and significantly reduced total harmonic

High Frequency vs. Low Frequency Solar

Jul 11, 2023 · What are the Differences? The majority of the differences stem from how to utilize these two different types of inverters. Consider this, when using

Inversion Methods Explained: High Frequency vs Low Frequency

4 days ago · INVERSION METHODS EXPLAINED High Frequency Inverters (HF) The large majority of inverters available in the retail market are high frequency. They are typically less

(PDF) Current Source Inverter (CSI) Power

Oct 28, 2023 · This study extensively investigates various categories of single-stage CSI photovoltaic inverters, categorizing them into two-level, three-level,

A comprehensive review of multi-level inverters, modulation,

Jan 3, 2025 · During the last decade, multilevel inverter (MLI) designs have gained popularity in GCPV applications. This article provides a wide-ranging investigation of the common MLI

Introduction to multilevel voltage source inverters

Jan 1, 2021 · Inverters have found a rapid evaluation in industrial applications compared to other power switching devices, due to their wide range of use. The foremost applications of inverters

A comprehensive review on inverter topologies and control strategies

Oct 1, 2018 · It is a fact that line-frequency transformers-based inverters have more weight and volume than transformerless inverters or high-frequency transformers-based inverters.

6 FAQs about [Is it good to have multiple voltages for industrial frequency inverters ]

Does a multilevel inverter work?

Normally, this method works, but in some applications, it creates problems, specifically where we do not require high distortion in the output voltage. The concept of a multilevel inverter (MLI) is a kind of modification of a two-level inverter.

What is a high frequency variable load inverter?

ut Pmax VINmax13:56MHz21:31kW375VIV. CONTROL SCHEMEA. Control ChallengesIn Section II the high frequency variable load inverter was modeled with each constituent inverter as an ideal voltage source that could drive any resistiv / inductive load, only sub-ject to maximum output voltage and current limits. However, real inverters h

What is a high frequency inverter?

The large majority of inverters available in the retail market are high frequency. They are typically less expensive, have smaller footprints, and have a lower tolerance for industrial loads. HF inverters have over twice the number of components and use multiple, smaller transformers.

What determines a high or low frequency inverter?

Size and tolerances of the transistors used in the inversion process, and the speed at which they operate determines the classification of high or low frequency. The large majority of inverters available in the retail market are high frequency.

Are inverters better than synchronous generators?

1. INTRODUCTION In the last decades, power systems have witnessed high penetration of renewable energy sources connected to the grid through power electronic converters. Compared to synchronous generators (SGs), inverters have low inertia and operate on a faster time scale.

Why do you need a multilevel converter?

The need for a multilevel converter is to provide high output power from a medium-voltage source. The multi-level inverter consists of several switches. The devices with lower ratings can generate higher voltage. An increase in the number of voltage levels produces a better voltage waveform..

Update Information

- Can the 96V industrial frequency inverter be used at home

- Mauritius 48v industrial frequency inverter

- Branded industrial frequency pure sine wave inverter

- Cuba Industrial Frequency Off-Grid Inverter

- Industrial frequency inverter 1kw

- Future Trends of High Frequency Inverters

- Price of Industrial Frequency Uninterruptible Power Supply

- Does the industrial frequency inverter increase the frequency

- British industrial frequency off-grid inverter brand

- Inverter has good high frequency and good low frequency

- Inverters are divided into high frequency and low frequency

- Industrial frequency inverter upgrade power

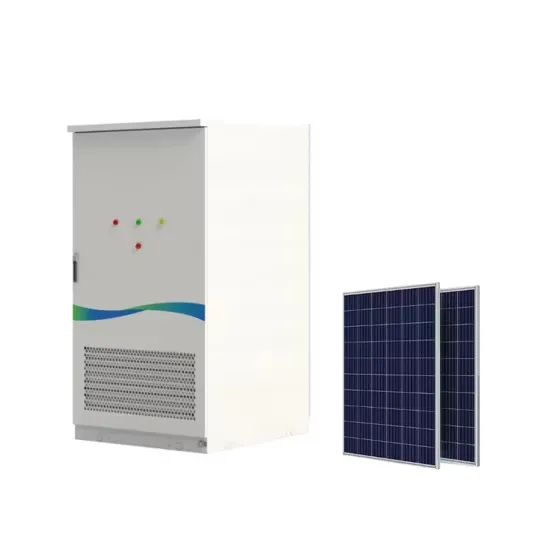

- The role of solar energy collection frequency conversion energy storage cabinet

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.