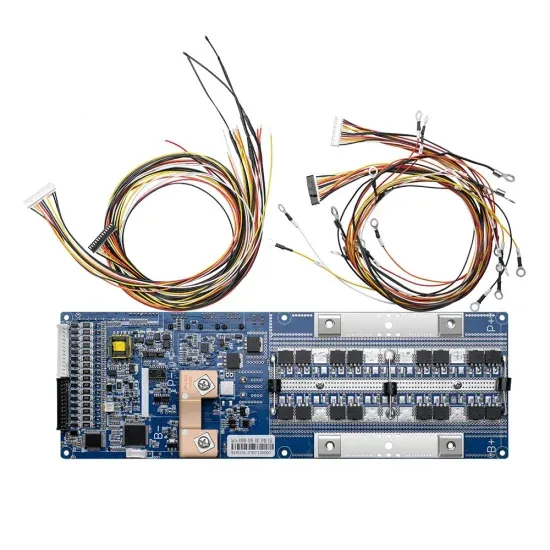

Battery management system and battery disconnect unit

The battery management system and electronical battery disconnect unit consist of several components designed to monitor, manage, control, and disconnect the battery cells of a

Battery Management Systems (BMS) [2025 List] | EV Battery

Battery management systems (BMS) are a critical component of electric vehicle (EV) batteries and energy storage systems (BESS) to ensure safe and efficient operation of the battery pack.

Wholesale 6s Battery Management System Manufacturer and

Aug 2, 2025 · 6s Battery Management System Manufacturers, Factory, Suppliers From China, To learn more about what we can do for you, contact us at any time. We look forward to

Battery Management Systems (BMS)

Oct 26, 2014 · Battery Management Systems (BMS) BMS means different things to different people. To some it is simply Battery Monitoring, keeping a check on the key operational

Battery Management Solutions for Energy Storage

Sep 12, 2023 · Minimize your system integration efort by leveraging our battery management expertise. Our engineers can also provide system design support to optimally configure your

What Is a BMS Battery? A Complete Guide for Beginners and

Apr 23, 2025 · What Does BMS Stand For? BMS stands for Battery Management System. It is an electronic control unit that monitors, manages, and protects rechargeable batteries, especially

Iceland BMS battery management system sales price

Battery management system (BMS) is technology dedicated to the oversight of a battery pack, which is an assembly of battery cells, electrically organized in a row x column matrix

Battery Management System (BMS) Detailed Explanation:

May 7, 2025 · Battery Management System (BMS) is the "intelligent manager" of modern battery packs, widely used in fields such as electric vehicles, energy storage stations, and consumer

Battery Management Systems in Electric Vehicles

Jun 1, 2024 · Summary <p>A battery management system (BMS) is one of the core components in electric vehicles (EVs). It is used to monitor and manage a battery system (or pack) in EVs.

Battery Management System | e.battery systems

A Battery Management System gets the best out of lithium-ion battery systems, ensuring multilevel electronic safety, longer lifespan, and improved performance. Our BMS measures all

Update Information

- Tirana BMS battery management control system manufacturer

- BMS battery management control system manufacturer in Hanoi

- Somalia BMS battery management power system manufacturer

- Moroni BMS battery management control system

- BMS battery management manufacturer in Manchester UK

- Battery Control BMS

- Windhoek BMS battery management power system composition

- Power battery energy management system BMS

- Is BMS battery management difficult

- The role of Haiti BMS battery management system

- Photovoltaic power supply BMS battery management system

- Battery Management System BMS and BBS

- Main functions of BMS battery management system

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.