什么是电池管理系统 (BMS)?

2 days ago · 电池管理系统模型:显示具有 Battery Coolant Control 模块的充电和放电电池模组组件。 (请 参阅 Simscape Battery 示例。 ) 电芯在不同温度

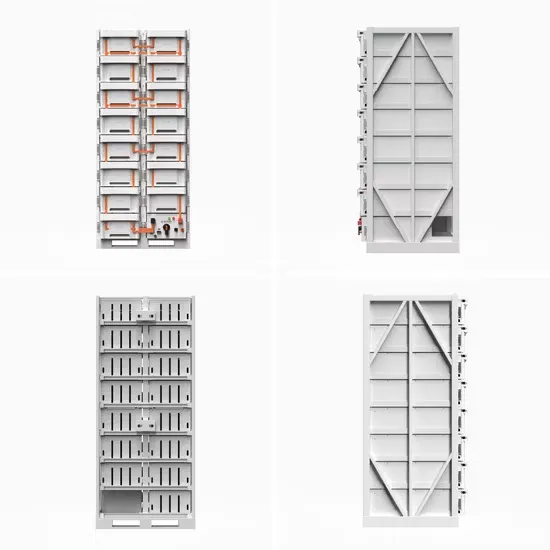

Battery management system and battery disconnect unit

The battery management system and electronical battery disconnect unit consist of several components designed to monitor, manage, control, and disconnect the battery cells of a

What Is a BMS? Battery Management System Explained

Aug 15, 2025 · A Battery Management System (BMS) is a digital control system designed to monitor, protect, balance, and optimize the operation of battery cells in an energy storage

Battery Management Systems in Electric Vehicles

Jun 1, 2024 · There are five main functions in terms of hardware implementation in BMSs for EVs: battery parameter acquisition; battery system balancing; battery information management;

Battery Management System (BMS) Detailed Explanation:

May 7, 2025 · Battery Management System (BMS) is the "intelligent manager" of modern battery packs, widely used in fields such as electric vehicles, energy storage stations, and consumer

Battery Management Systems (BMS)

Aug 28, 2023 · A Battery Management System (BMS) is an electronic system that manages and monitors rechargeable batteries, ensuring their safe and eficient operation. It consists of

电池管理系统BMS知识与功能,一篇入门

Aug 26, 2021 · 1)什么是BMS? BMS全称是Battery Management System, 电池管理系统。它是配合监控储能电池状态的设备,主要就是为了智能化管理及维

Battery Management System (BMS) for Efficiency and Safety

Jan 5, 2025 · A Battery Management System (BMS) is an electronic system designed to monitor, regulate, and protect rechargeable batteries. It is responsible for balancing the charge across

Understanding Battery Management Systems: The Key to

Sep 24, 2024 · Conclusion A Battery Management System is crucial for anyone utilizing rechargeable batteries, whether in electric vehicles, renewable energy systems, or everyday

Battery Management System (BMS) Architecture:

Oct 14, 2024 · The Battery Management System (BMS) is a crucial component in ensuring the safe and efficient operation of lithium-ion battery packs in electric

Understanding Battery Management Systems (BMS):

Jan 18, 2025 · A Battery Management System (BMS) plays a crucial role in modern energy storage and electrification applications. It oversees a battery pack''s operational health,

What Is a BMS Battery? A Complete Guide for Beginners and

Apr 23, 2025 · What Does BMS Stand For? BMS stands for Battery Management System. It is an electronic control unit that monitors, manages, and protects rechargeable batteries, especially

Battery Management Systems (BMS)

Oct 26, 2014 · It shows the three main BMS building blocks, the Battery Monitoring Unit (BMU), the Battery Control Unit (BCU) and the CAN bus vehicle communications network and how

来,一篇文章向你说清楚什么是BMS(电池管理系

Jun 6, 2025 · 电池管理系统 (Battery Management System,BMS)是电池应用中的核心控制单元,被誉为电池的"保姆"或"管家"。它通过智能化管理电池的

What is a Battery Management System? Complete Guide to BMS

Aug 3, 2025 · A Battery Management System (BMS) is an electronic control unit that monitors and manages rechargeable battery packs to ensure safe operation, optimal performance, and

Battery Management Systems in Electric Vehicles

Jun 1, 2024 · Summary <p>A battery management system (BMS) is one of the core components in electric vehicles (EVs). It is used to monitor and manage a battery system (or pack) in EVs.

Battery management system

Sep 24, 2021 · Battery monitoring by estimating the battery pack state of charge (SoC) and state of health (SoH) during charging and discharging. Battery optimization thanks to cell balancing

6 FAQs about [Moroni BMS battery management control system]

What is battery management system (BMS)?

Battery Management System (BMS) is the “intelligent manager” of modern battery packs, widely used in fields such as electric vehicles, energy storage stations, and consumer electronics.

What is a battery management system?

The battery management system includes a battery control unit and multiple cell supervision circuits. The electronic disconnect unit serves as an all-in-one solution that integrates a battery disconnect unit, a battery management system, and optionally the cell monitoring units. based on volume production possible due to global production network

What is a battery management system & electronical battery disconnect unit?

The battery management system and electronical battery disconnect unit consist of several components designed to monitor, manage, control, and disconnect the battery cells of a battery-electric or plug-in hybrid vehicle. The battery management system includes a battery control unit and multiple cell supervision circuits.

How will BMS technology change the future of battery management?

As the demand for electric vehicles (EVs), energy storage systems (ESS), and renewable energy solutions grows, BMS technology will continue evolving. The integration of AI, IoT, and smart-grid connectivity will shape the next generation of battery management systems, making them more efficient, reliable, and intelligent.

What makes a good battery management system?

A BMS must be designed for specific battery chemistries such as: 02. Power Consumption: An efficient BMS should consume minimal power to prevent draining the battery unnecessarily. 03. Scalability: For large-scale applications (EVs, grid storage), a scalable BMS is essential.

What does a BMS do?

History - (Log Book Function) Monitoring and storing the battery's history is another possible function of the BMS. This is needed in order to estimate the State of Health of the battery, but also to determine whether it has been subject to abuse.

Update Information

- Reykjavik BMS battery management control system manufacturer

- Tirana BMS battery management control system manufacturer

- Zimbabwe BMS Battery Management Control System Company

- BMS battery management control system manufacturer in Hanoi

- Photovoltaic power supply BMS battery management system

- BMS Battery Management Power Systems Mexico

- BMS battery management introduction

- BMS battery management system increases power consumption

- Djibouti energy storage BMS battery management system

- Main functions of Mongolia BMS battery management system

- The main function of the battery management system BMS

- Battery Management System BMS and BBS

- The role of Haiti BMS battery management system

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.