Aluminum Foil Anodes for Li-Ion Rechargeable

Feb 25, 2022 · Lithium-ion battery electrodes contain a substantial amount of electrochemically inactive materials, including binders, conductive agents, and

Advances in Structure and Property Optimizations of Battery Electrode

Nov 15, 2017 · The intrinsic structures of electrode materials are crucial in understanding battery chemistry and improving battery performance for large-scale applications. This review

Recent developments on electrode materials and electrolytes

May 10, 2024 · The former is connected to the battery''s energy storage functionality, and the latter is related to the playing stabilizing the electrode components. Binders are a vital passive

Non-aqueous rechargeable aluminum-ion batteries (RABs):

Sep 29, 2024 · To meet the growing energy demand, it is imperative to explore novel materials for batteries and electrochemical chemistry beyond traditional lithium-ion batteries. These

Electrode materials for lithium-ion batteries

Dec 1, 2018 · In recent years, the primary power sources for portable electronic devices are lithium ion batteries. However, they suffer from many of the limitations for their use in electric

Unlocking an Aluminum Anode in the Nonaqueous

Jun 26, 2025 · In this review, we systematically summarize the characteristics and anode reactions in four nonaqueous electrolyte systems (an ionic liquid, a deep eutectic solvent,

Towards sustainable energy storage of new low-cost aluminum batteries

Feb 28, 2025 · Fig. 1 (D) outlines the study''s framework, divided into four main sections: Types of Al batteries, according to the electrolyte characteristics, Al batteries can be briefly classified

Surface Evolution of Aluminum Electrodes in Non-Aqueous Aluminum Batteries

Oct 1, 2020 · Using in situ optical observation and simulation methods, the results suggest that dendrite growth and deposition on the aluminum electrode surface is critical to the aluminum

The Difference Between Steel-shell, Aluminum

Nov 10, 2020 · The shell materials used in lithium batteries on the market can be roughly divided into three types: steel shell, aluminum shell and pouch cell

Laminated tin–aluminum anodes to build practical aqueous aluminum batteries

Feb 1, 2024 · Aqueous aluminum metal batteries (AAMBs) have emerged as promising energy storage devices, leveraging the abundance of Al and their high energy density. However,

The electrodes of new energy battery cabinets are made of aluminum

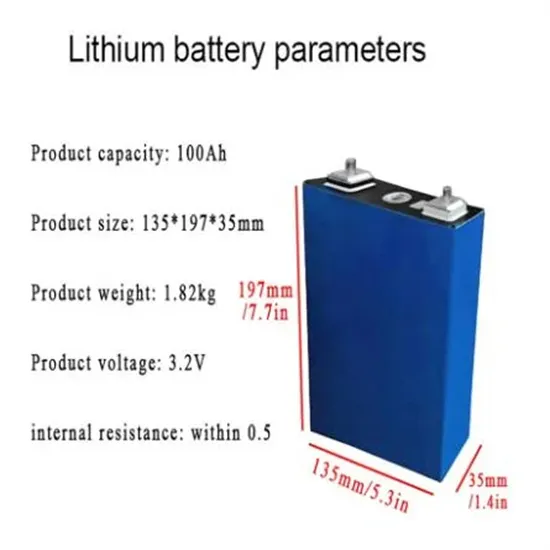

Rechargeable aluminum batteries with aluminum metal as a negative electrode have attracted wide attention due to the aluminum abundance, its high theoretical capacity and stability under

Aluminum Ion Batteries: Electrolyte and Anode

May 1, 2025 · We present a comprehensive and systematic review of the development process, basic physical and chemical properties, electrochemistry, and failure mechanisms of

Strategies toward the development of high-energy-density lithium batteries

May 30, 2024 · Strategies such as improving the active material of the cathode, improving the specific capacity of the cathode/anode material, developing lithium metal anode/anode-free

Nonmetal Current Collectors: The Key Component for High-Energy

Although significant progress has been made on positive electrode materials, the effective energy density of aluminum batteries is still limited by the presence of high-density refractory metal

Advancing aluminum-ion batteries: unraveling the charge

Nov 18, 2024 · Since their inception, lithium-ion batteries (LIBs) have revolutionized electrical energy storage, paving the way for the widespread adoption of electric vehicles and the

Towards optimal 3D battery electrode architecture:

May 1, 2024 · The rapid evolution of energy storage devices, driven by increasing demands for prolonged battery life in electronics as well as sustainable energy solutions has elevated

Optimizing lithium-ion battery electrode manufacturing:

Aug 1, 2024 · The overall performance of lithium-ion battery is determined by the innovation of material and structure of the battery, while it is significantly dependent on the progress of the

Aluminum Foil Anodes for Li-Ion Rechargeable Batteries:

ACCESS ABSTRACT: Lithium-ion battery electrodes contain a substantial amount of electrochemically inactive materials, including binders, conductive agents, and current

6 FAQs about [The electrodes of new energy battery cabinets are made of aluminum]

Can molten aluminum salt electrolytes be used to assemble non aqueous aluminum batteries?

The low ionic conductivity of deep eutectic solvents and the high-temperature operating conditions required for molten inorganic aluminum salt electrolytes make them non-ideal choices for assembling room-temperature non-aqueous aluminum batteries.

Can aluminum anodes be used for aqueous aluminum-ion batteries?

Therefore, untreated aluminum anodes and ionic liquid-modified aluminum anodes are unlikely to become preferred anode materials for aqueous aluminum-ion batteries, making it difficult to expand the industrial application prospects of such batteries.

What are the cathode materials for non-aqueous aluminum dual-ion batteries?

The cathode materials for non-aqueous aluminum dual-ion batteries are typically carbon-based materials (graphene [64, 70, 106], carbon nanotubes [107, 108]).

Why are zinc anodes better than aluminum ion batteries?

They not only inherit the high theoretical capacity of aluminum-ion batteries but also benefit from the superior plating/stripping characteristics of zinc anodes in aqueous electrolytes.

Are aqueous aluminum-ion batteries the future of energy storage?

Aqueous aluminum-ion batteries hold promises for advanced energy storage systems due to their cost-effectiveness, air stability, and eco-friendliness. However, their development is significantly hindered by the intrinsic limitations of aluminum anodes and aluminum-based electrolytes.

What are the two main electrodes in a lithium ion battery?

Batteries comprise two main electrodes: the anode, where oxidation occurs, releasing electrons into the circuit during discharge, often made of graphite or lithium metal in rechargeable lithium-ion batteries, and the cathode, where reduction happens, combining ions from the electrolyte with electrons from the circuit.

Update Information

- Are new energy battery cabinets fragile

- Where are the new energy battery cabinets produced

- Introduction to new energy battery cabinets

- What battery cabinets are used in Gambia New Energy

- New Energy Battery Cabinet Aluminum

- What are the energy storage new energy battery cabinets included in

- Japanese City New Energy Battery Cabinet Controller

- New energy installation of original battery cabinet

- New lithium battery energy storage cabinet equipment

- Analysis on the development prospects of new energy storage cabinets

- What metals does the new energy battery cabinet contain

- African new energy battery cabinet manufacturing company

- New Energy Battery Cabinet Cooling

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.