Numerical Simulation and Optimal Design of Air Cooling Heat Dissipation

Jan 1, 2022 · Effective thermal management can inhibit the accumulation and spread of battery heat. This paper studies the air cooling heat dissipation of the battery cabin and the influence

Energy storage battery cabinet heat dissipation method

A heat dissipation control method of an air-cooled and liquid-cooled integrated energy storage cabinet belongs to the technical field of energy storage cabinet structures, and comprises the

principle of heat dissipation system of energy storage cabinet

Design and Optimization of Heat Dissipation for a High-Voltage Control Box in Energy Storage Systems The high-voltage control box is positioned at the upper part of the energy storage

Research on Heat Dissipation of Cabinet of Electrochemical Energy

It is of great significance for promoting the development of new energy technologies to carry out research on the thermal model of lithium-ion batteries, accurately describe and predict the

How does the new energy battery cabinet dissipate heat

ant with the rapid development of new energy vehicles. This paper presents a novel cooling structure for cylindrical power batteries, which cools the battery with heat pipes and use liquid

Battery cabinet heat dissipation

A thermal management system for an energy storage battery The results show that the heat dissipation effect of optimized solution 4 is significantly better than other solutions, and its

battery energy storage cabinet heat dissipation method

Design and Optimization of Heat Dissipation for a High-Voltage Control Box in Energy Storage Abstract. To address the issue of excessive temperature rises within the field of electronic

Energy storage battery cabinet heat dissipation

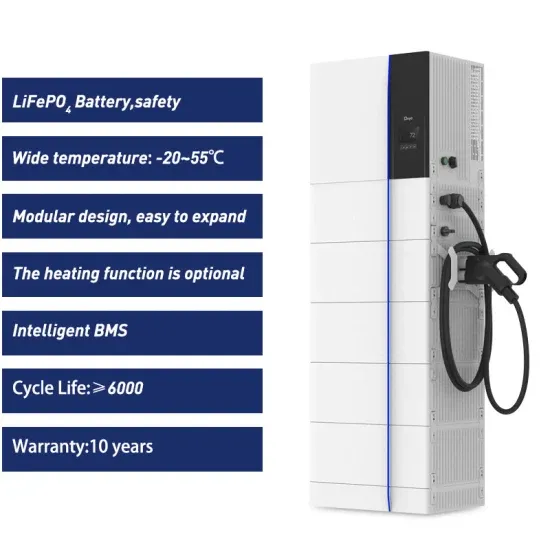

The 115kWh air cooling energy storage system cabinet adopts an "All-In-One" design concept, with ultra-high integration that combines energy storage batteries, BMS (Battery

Working principle of heat dissipation of new energy

Working principle of the heat dissipation system. The heat dissipation system plays a crucial role in the lithium-ion battery pack of electric vehicles, and its working principle

Numerical Simulation and Optimal Design of Air Cooling Heat Dissipation

Jan 1, 2022 · Abstract Lithium-ion battery energy storage cabin has been widely used today. Due to the thermal characteristics of lithium-ion batteries, safety accidents like fire and explosion

Design and simulation analysis of physical heat dissipation structure

Nov 1, 2023 · In order to understand the physical heat dissipation structure of welding robot controllers, the author proposes a research based on the design and si

New energy battery cabinet heat dissipation vent

Where is the heat dissipation vent of the new energy battery pack This paper reviews the heat dissipation performance of battery pack with different structures (including: longitudinal battery

Optimization of liquid cooled heat dissipation structure

Jun 27, 2024 · technology, as a widely used thermal management method, is crucial for maintaining temperature stability and uniformity during battery operation (Karimi et al., 2021).

Design and optimization of air-cooled heat dissipation structure

Jul 15, 2024 · As a new type of energy storage device, supercapacitor is considered an electrochemical energy storage technology that could widely replace lithium-ion batteries in

Energy storage battery cabinet heat dissipation principle

By interacting with our online customer service, you''ll gain a deep understanding of the various Energy storage battery cabinet heat dissipation principle diagram featured in our extensive

What is the heat dissipation principle of the energy storage battery

Heat dissipation characteristics are investigated under different ventilation schemes. The best cell arrangement structure and ventilation scheme are obtained. Influence of four parameters on

Thermal Simulation and Analysis of Outdoor Energy Storage Battery

Jan 8, 2024 · We studied the fluid dynamics and heat transfer phenomena of a single cell, 16-cell modules, battery packs, and cabinet through computer simulations and experimental

Working principle of heat dissipation of new energy

Does a battery pack have a complex heat dissipation mechanism? Thermal flow fields of different air outlet modes were considered,and the results of this research provide a theoretical basis

Research on Heat Dissipation of Cabinet of Electrochemical Energy

According to the actual size of a company''s energy storage products, this paper also considered the liquid cooling cooling system, air cooling cooling system and lithium-ion battery module

New Energy Storage Cabinet Heat Dissipation

Does airflow organization affect heat dissipation behavior of container energy storage system? In this paper,the heat dissipation behavior of the thermal management system of the container

Simulation of heat dissipation model of lithium-ion

Some simulation results of air cooling and phase change show that phase change cooling can control the heat dissipation and temperature rise of power battery well. The research in this

Topology optimization of liquid cooling plate for lithium battery heat

Oct 1, 2024 · Considering the safety and effectiveness of lithium-ion batteries for new-energy vehicles under extreme working conditions, a topology optimization design method based on a

New Energy Battery Cabinet Heat Dissipation Design Solution

heat dissipation structure of vehicle mounted energy storage batteries. The current research status of NSGA-II both domestically and internationally is analyzed. The second part proposes

Multi-scale modelling of battery cooling systems for grid

Feb 22, 2025 · The introduction of battery energy storage systems is crucial for addressing the challenges associated with reduced grid stability that arise from the large-scale integration of

Working principle of heat dissipation of new energy

Thermal flow fields of different air outlet modes were considered,and the results of this research provide a theoretical basis for further revealing the complex heat dissipation mechanismof the

Battery cabinet with heat dissipation structure

The utility model provides a heat radiation structure''s battery cabinet, belong to battery cabinet technical field, after solving the full storage battery in the battery cabinet, the battery is given

Analysis of Influencing Factors of Battery Cabinet Heat Dissipation

Safety is the lifeline of the development of electrochemical energy storage system. Since a large number of batteries are stored in the energy storage battery cabinet, the research on their heat

Study on heat dissipation structure of air-cooled

Jan 1, 2022 · Under the condition of comprehensive consideration of the battery volume energy density and heat dissipation energy consumption, the final

5 FAQs about [New energy battery cabinet heat dissipation structure]

Does guide plate influence air cooling heat dissipation of lithium-ion batteries?

Due to the thermal characteristics of lithium-ion batteries, safety accidents like fire and explosion will happen under extreme conditions. Effective thermal management can inhibit the accumulation and spread of battery heat. This paper studies the air cooling heat dissipation of the battery cabin and the influence of guide plate on air cooling.

Does guide plate influence air cooling heat dissipation?

Effective thermal management can inhibit the accumulation and spread of battery heat. This paper studies the air cooling heat dissipation of the battery cabin and the influence of guide plate on air cooling. Firstly, a simulation model is established according to the actual battery cabin, which divided into two types: with and without guide plate.

What is lithium-ion battery energy storage cabin?

Lithium-ion battery energy storage cabin has been widely used today. Due to the thermal characteristics of lithium-ion batteries, safety accidents like fire and explosion will happen under extreme conditions. Effective thermal management can inhibit the accumulation and spread of battery heat.

How to simulate a battery cabin?

Firstly, a simulation model is established according to the actual battery cabin, which divided into two types: with and without guide plate. Then, at the environment temperature of 25°C, the simulation air cooling experiment of the battery cabin was carried out. The working condition of module was 1C, and the air speed was set to 4m/s.

How to improve the air cooling effect of battery cabin?

The air cooling effect of battery cabin was improved by adding guide plate. There is better consistency between the modules and the modules can operate at more appropriate environment temperature. Content from this work may be used under the terms of the Creative Commons Attribution 3.0 licence.

Update Information

- New Energy Battery Cabinet Base Station Power Structure

- New Energy New Energy Battery Cabinet Structure

- New Energy Battery Cabinet Aluminum

- New Energy Battery Cabinet Pre-charge Resistance

- Georgetown New Energy Telecommunication Power Supply Battery Cabinet Factory

- New Energy Battery Cabinet Communication Power Solution

- New Energy Battery Cabinet Modification

- Recommendation of lithium battery energy storage cabinet for charging pile in New Delhi

- How much does it cost to swap a new energy battery cabinet

- New Energy 18 3 Battery Cabinet Price

- What is the most suitable size for a new energy battery cabinet

- Can new energy be equipped with a battery cabinet

- How much negative charge does the new energy battery cabinet have

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

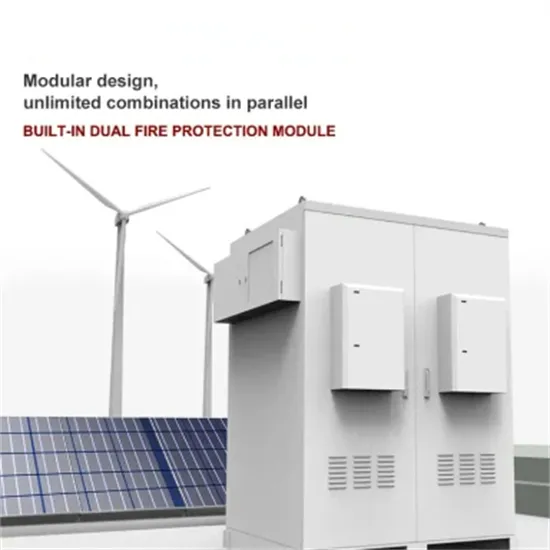

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.