VRVIII-S Outdoor Units Guide Spec

May 22, 2021 · The compressor shall be mounted on vibration dampening rubber grommets to minimize the transmission of vibration, eliminating the standard need for external spring isolation.

Fundamentals of Electrodynamic Vibration Testing

Jun 19, 2020 · The electronics for an electrody-namic shaker have become so compact that the inverters, magnet-ic field power supply, vibration controller, electrical interconnects, and any

CHAPTER 48. NOISE AND VIBRATION CONTROL

Dec 15, 2015 · System analysis for noise control uses the source-path-receiver concept. The source of the sound is the noise-generating mechanism. The sound travels from the source via

Transformer Vibrations Monitoring

May 15, 2025 · Transformer Vibrations Monitoring The POWER VIEW TVM is a permanently installed transformer monitoring system that uses a matrix of vibration sensors and load

What is shock and vibration limits of these power supplies

Dec 8, 2022 · - Endurance at critical frequencies (Q > 2) 90 minutes / axis or 30 Hz if no critical frequency. - Semi-sinusoidal 15 g, duration 11 ms. - Three positive and negative shocks per

Fisher FIELDVUE 4400 Digital Position Transmitter

Aug 15, 2025 · Digital Position Transmitter The Fisher FIELDVUE 4400 transmitter senses the position of rotary or sliding-stem valves, vents, dampers or other devices. It provides a precise

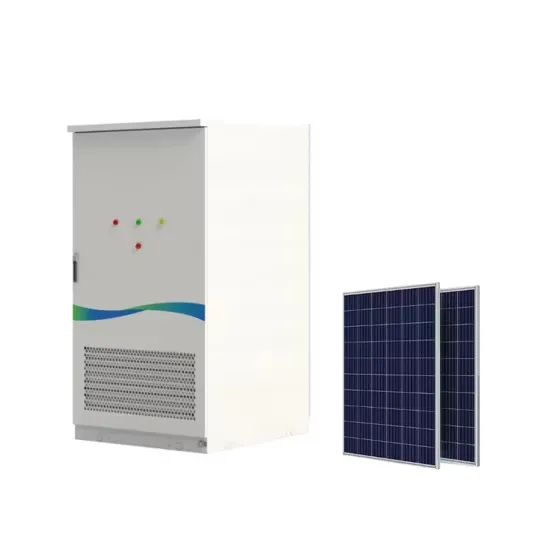

Outdoor energy storage power supply export

Introducing our 150W outdoor energy storage power supply, a reliable and portable mobile power source for your camping and outdoor adventures! Equipped with high capacity batteries, this

Measuring vibrations

6 days ago · Manufacturers supplying power tools within the European Union are responsible for measuring and declaring the vibration emission value for every machine model. To find out

Guideline Selection of safety standards for power

Apr 29, 2022 · power supply units, chokes and corresponding combinations. With part -2-16, a standard has been created that addresses the special requirements and testing of switching

Shop for Good Vibrations Outdoor Power Equipment at Tractor Supply

7 items in Outdoor Power Equipment Good Vibrations Z-Hitch 3-Way Zero-Turn Mower Hitch Plate 4.4 (40) Item # 173602299 PickupFreeAvailabletoday Same Day Delivery Standard

IEEE 525-2007_accepted

May 23, 2010 · IEEE-SA Standards Board Abstract: The design, installation, and protection of wire and cable systems in substations are covered in this guide, with the objective of minimizing

Outdoor Power System Design and Cost Considerations

Jun 14, 2012 · Most power conversion, protection and backup systems used outdoors are actually designed for indoor conditions. These systems fail quickly in harsh outdoor environments.

6 FAQs about [Outdoor power supply vibration standard]

Do power tools have a vibration value?

Manufacturers are required to declare and supply the vibration value with every power tool sold within the European Union (part of the CE certification). The vibration value is based on measurements performed in accordance with the procedures described in emission standards.

What is a ptible power supply?

ptible power supplies therefore refer back to IEC 62477-1.IEC/EN 61204-7 is also referenced in 60204-1, one of the most important standards for electrical equipment in mechanical e gineering, in the requirements for control power supplies. This hel

Who is responsible for vibrations in power tools?

xxThe operator is responsible for using the tools according to the given instructions and to react when there is reason to believe that vibrations are unusually high. Manufacturers are required to declare and supply the vibration value with every power tool sold within the European Union (part of the CE certification).

What is a vibration value based on?

The vibration value is based on measurements performed in accordance with the procedures described in emission standards. As of 2018, ISO 28927 series of standards and EN62841 are the valid emission standards for pneumatic and electric tools.

Who is responsible for reducing vibration exposure?

Everyone, from manufacturer to operator, is responsible to reduce the vibration exposure. Manufacturers supplying power tools within the European Union are responsible for measuring and declaring the vibration emission value for every machine model. To find out more on how we measure vibrations, continue reading.

What is W voltage with DC output - part 7?

w voltage with DC output - Part 7: Safety requirements“. In the first editio of this standard, reference was made back to IEC 60950-1. In the second and currently valid edition of this standard, IEC 62477-1 is used as

Update Information

- The best portable outdoor power supply

- Banjul portable outdoor power supply manufacturer

- Outdoor power supply rainproof floor box

- Pyongyang outdoor communication power supply BESS price in the same city

- Outdoor mobile energy storage power supply in Manchester UK

- Algeria outdoor power supply sales

- Dublin Photovoltaic Folding Container Outdoor Power Supply

- Vietnam Ho Chi Minh outdoor UPS uninterruptible power supply

- Boost module production outdoor power supply

- Outdoor power supply brand introduction

- Outdoor power supply temperature resistance

- European outdoor power supply OEM manufacturer

- Slovakia outdoor power supply prices

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.