What Are the Different Types of Battery Management Systems (BMS)?

Dec 6, 2023 · Battery Management Systems (BMS) are essential for monitoring and managing battery performance, ensuring safety, and prolonging lifespan. The main types include

Q1. What is a BMS? Types of BMS and differentiate the

Jan 9, 2023 · The BMS will also control the recharging of the battery by redirecting the recovered energy (i.e., from regenerative braking) back into the battery pack (typically composed of a

Understanding Battery Management Systems (BMS):

Jan 18, 2025 · A Battery Management System (BMS) plays a crucial role in modern energy storage and electrification applications. It oversees a battery pack''s operational health,

Next-generation battery energy management systems in

This article proposes a comprehensive overview of the potential of artificial intelligence (AI) and its subsets-machine learning (ML) and deep learning (DL) in next-generation battery energy

A comprehensive review of BMS fault analysis in pure

Abstract. Pure electric vehicle technology faces numerous technical challenges during the process of independent research and development, with the safety and endurance of power

A review of battery energy storage systems and advanced battery

May 1, 2024 · Battery management systems (BMS) are crucial to the functioning of EVs. An efficient BMS is crucial for enhancing battery performance, encompassing control of charging

SIGNAL AND POWER CONNECTOR SYSTEMS FOR EV

Jul 4, 2025 · SIGNAL AND POWER CONNECTOR SYSTEMS FOR EV BATTERIES The battery management system (BMS) is critical for optimum battery performance and safety. It must

A Review on lithium-ion battery thermal management

Jan 25, 2023 · This classification can provide a benchmark for researchers to better interpret and understand all BTMS functions, including battery cooling, battery heating, and battery thermal

Types of Battery Management Systems (BMS): A Guide to

Feb 17, 2025 · A BMS is the "brain" of any battery-powered system. It monitors voltage, temperature, and current, prevents overcharging/overheating, and balances cell performance.

Classification of BMS battery protection boards

Apr 28, 2025 · BMS (Battery Management System) protection board is the core component of lithium battery safety and performance management. Its classification methods are diverse,

Battery Management System (BMS) Detailed Explanation:

May 7, 2025 · Battery Management System (BMS) is the "intelligent manager" of modern battery packs, widely used in fields such as electric vehicles, energy storage stations, and consumer

AN215 Functional Safety Concept for BMS Solution:

Feb 5, 2025 · The power supply architecture implemented in this concept ensures independence from the supply point of view between the BM&P and the MCU. The BM&P is connected

Classification, summarization and perspectives on state-of

Jul 1, 2021 · Naturally, well-designed battery management system (BMS) is essential to ensure reliable and safe operation of EVs. Battery state estimation is one of core features in BMS,

6 FAQs about [Power battery classification by BMS]

What are the different types of battery management systems?

In terms of functionality, Battery Management Systems (BMSs) may be divided into three categories: centralized, modular or master-slave, and distributed. In a centralized BMS, parameters such as voltage, current, and temperature are measured for individual cells and sent to the main BMS board.

What is battery management system (BMS)?

Battery Management System (BMS) plays an essential role in optimizing the performance, safety, and lifespan of batteries in various applications.

How do I choose a battery management system (BMS)?

When choosing a BMS, consider the following factors to make an informed decision: Battery Chemistry Compatibility: Different battery chemistries require specific BMS functionalities. Ensure that the BMS you choose is designed for your battery chemistry, such as Li-ion, lead-acid, or nickel-based batteries.

What makes a good battery management system?

A BMS must be designed for specific battery chemistries such as: 02. Power Consumption: An efficient BMS should consume minimal power to prevent draining the battery unnecessarily. 03. Scalability: For large-scale applications (EVs, grid storage), a scalable BMS is essential.

What is a lithium ion BMS?

Based on Battery Chemistry: Li-ion BMS, Lead-acid BMS, and Nickel-based BMS Li-ion BMS is specifically designed for Li-ion battery chemistries, which are widely used in applications such as electric vehicles, portable electronics, and renewable energy systems.

What is a Li-ion battery monitoring system (BMS)?

Li-ion BMS is specifically designed for Li-ion battery chemistries, which are widely used in applications such as electric vehicles, portable electronics, and renewable energy systems. These BMS units employ sophisticated algorithms to monitor cell voltages, temperatures, and currents.

Update Information

- Comoros BMS battery management power system composition

- BMS battery management system increases power consumption

- Windhoek BMS battery management power system composition

- BMS Battery Management Power Systems Mexico

- Power battery energy management system BMS

- BMS battery management system power off

- Phnom Penh power battery bms standard

- Photovoltaic power supply BMS battery management system

- Brunei power lithium battery bms solution

- Power battery BMS supporting

- Telecom site displays battery cabinet base station power

- Silver ion battery outdoor power supply

- Single power tool lithium battery

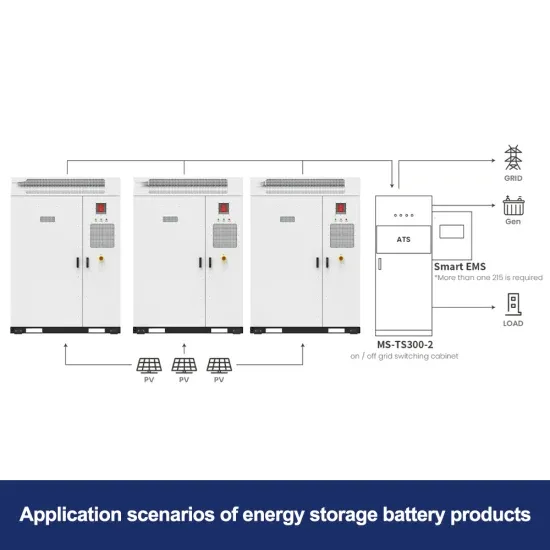

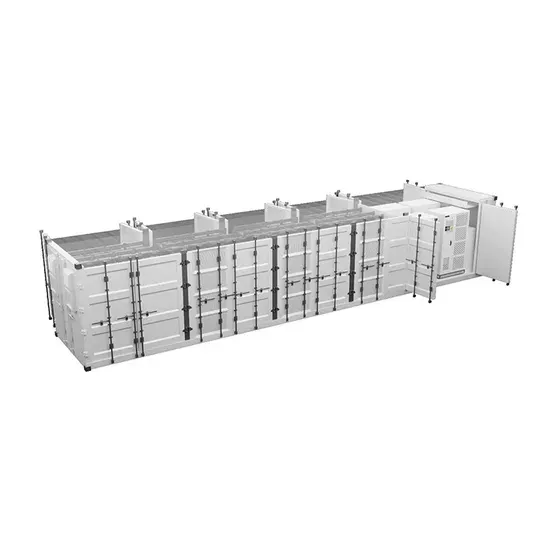

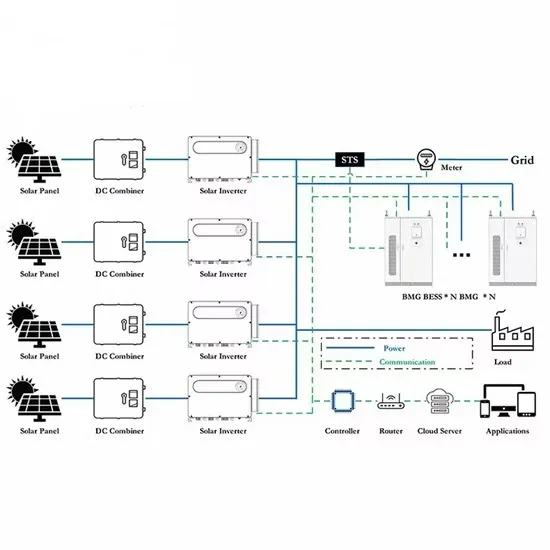

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.