Lithium Battery Applications for Power Tools

Power tool batteries usually require high C rate battery packs, PLS Battery, as one of lithium ion battery manufacturers, usually use featured lithium ion batteries for custom lithium battery

How Long Will A Power Tool Battery Last?

May 19, 2023 · Factors affecting battery life The lifespan of a power tool battery depends on several factors: Type of battery: Lithium-ion batteries are the most commonly used batteries in

Lithium Batteries in Power Tools: A Performance

Aug 16, 2025 · In this article, we will explore the benefits of lithium batteries in power tools, compare them to older battery technologies, and evaluate their

Makita BL1850B 18V LXT® Lithium-Ion 5.0Ah

Dec 23, 2014 · The 18V LXT 5.0Ah battery (BL1850) is compatible only with Star Protection tools, indicated by the Star Symbol and/or Yellow Battery Receiver

3 Best Lithium Ion Power Tool Batteries for Small Home

4 days ago · Discover the top 3 lithium-ion power tool batteries for DIY projects. Compare Milwaukee, DeWalt & Makita options with runtime, pricing & performance insights to boost

How to Choose the Right Lithium-Ion Battery-Powered Power Tools?

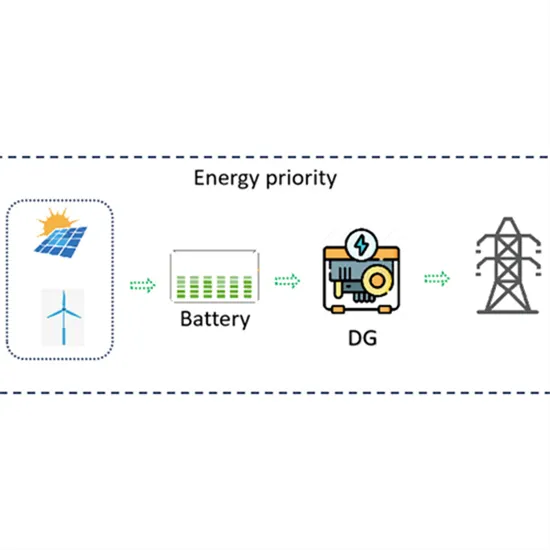

Li-ion battery pack: Converts chemical energy to electricity. Motor: Drives the tool head via a transmission system (e.g., drilling, cutting). Control circuit: Monitors battery status, regulates

Power Tool Batteries: A Comprehensive Guide —

Nov 18, 2024 · Lithium-ion (Li-ion): Li-ion is the dominant chemistry for power tool batteries today. They offer the highest energy density, allowing for lighter and

RYOBI P108 4AH One+ High Capacity Lithium Ion Battery for RYOBI Power

Jul 26, 2013 · RYOBI P108 4AH One+ High Capacity Lithium Ion Battery for RYOBI Power Tools (Single Battery) : Amazon.ca: Tools & Home ImprovementThe P108 is the strongest battery in

Fires Linked to Power Tool Batteries

Apr 10, 2024 · Fires Linked to Power Tool Batteries In manufacturing more fires are happening because of power tool batteries, especially the lithium-ion type. Understanding the risk is

Power Tool Batteries: High-Performance Lithium Solutions

Experience unmatched performance with Vade Battery''s custom lithium power solutions for screwdrivers, tire pressure monitors, and more. Our professional-grade power tool batteries

Amazon : Octopus Ready Multi Power Tool

Jul 18, 2024 · About this item [Universal Compatibility] Charge up to 4 batteries regardless of their brands, and free yourself from preparing separate chargers

6 FAQs about [Single power tool lithium battery]

What are power tool batteries?

Power tool batteries have come a long way from bulky nickel-cadmium (NiCd) packs. Today, lithium-ion (Li-ion) technology dominates the market, offering greater power, longer runtimes, and lighter weights. This guide dives into the world of power tool batteries, exploring different chemistries, voltage platforms, amp-ho

Which chemistry is best for power tool batteries?

However, they had a higher self-discharge rate and were susceptible to damage from overcharging and overheating. Lithium-ion (Li-ion): Li-ion is the dominant chemistry for power tool batteries today. They offer the highest energy density, allowing for lighter and more powerful tools.

What is the best battery for a cordless tool?

The Ryobi 18V ONE+ High Capacity Battery offers great value. It works with over 280 (and counting!) of Ryobi’s tools, making it a super affordable way to build a versatile cordless collection. Ryobi also have a range of 40v batteries. For those loyal to Team Blue, the Bosch 18V Power for All Battery lives up to its name.

How can cordless tool batteries improve performance & efficiency?

Several emerging trends and innovations are on the horizon to address these challenges and improve the performance and efficiency of cordless tool batteries. Solid-state batteries use solid electrolytes instead of liquid or gel electrolytes, which can improve the energy density, safety, and durability of the batteries.

What is a good charge level for a power tool battery?

A charge level around 40-60% is ideal for storage. Use the Correct Charger: Always use the manufacturer's recommended charger for your specific battery type. Clean Battery Contacts: Periodically clean the battery contacts with a clean, dry cloth to ensure a good connection. The Future of Power Tool Batteries:

What tools need a high voltage battery?

Type of Tool: High-power tools like circular saws and angle grinders require higher voltage and Ah ratings. Drills and impact drivers can often use lower voltage platforms for lighter tasks. Frequency of Use: For frequent use, invest in higher Ah batteries to minimize downtime for charging.

Update Information

- Italian power tool lithium battery

- Helsinki Power Tool Lithium Battery

- Single lithium battery outdoor power supply

- Power tool lithium battery voltage and battery quantity

- Slovenia power tool lithium battery manufacturer

- Nassau Power Tool Lithium Battery

- Power tool lithium battery has low power storage

- Ukrainian tool lithium battery price

- Phnom Penh lithium battery outdoor power brand

- Ghana lithium battery outdoor power supply price

- Cheap lithium battery power station Price

- Banjul Tool Lithium Battery Enterprise

- Black Mountain Outdoor Power Lithium Battery Company

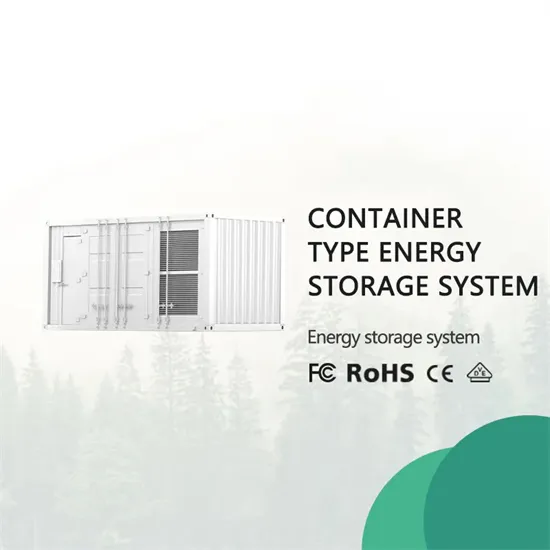

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.