Turkmenistan Ice Thermal Energy Storage Market (2025

Market Forecast By Storage Type (Static Ice Storage, Dynamic Ice Storage, Ice-On-Coil Storage, Encapsulated Ice Storage, Hybrid Storage), By System Component (Ice Tanks, Heat

Containerized Energy Storage Solutions in Balkanabat Turkmenistan

Specializing in hybrid energy solutions for harsh environments, we deliver turnkey storage systems with remote monitoring capabilities. Contact our team to discuss customized projects:

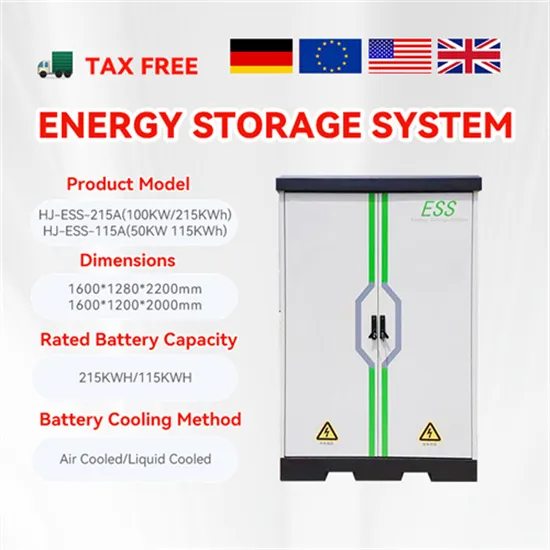

3440 KWh-6880KWh Liquid-Cooled Energy Storage Container System

We''s cutting-edge Liquid-Cooled Energy Storage Container System, armed with 280Ah lithium iron phosphate batteries, fuses cutting-edge design principles. Boasting intelligent liquid

2.5MW/5MWh Liquid-cooling Energy Storage System

Oct 29, 2024 · The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20''GP container, thermal management system, firefighting system, bus unit, power distribution unit,

Top 10 liquid cooling energy storage

Top 10 liquid cooling energy storage Furthermore, the energy storage mechanism of these two technologies heavily relies on the area''''s topography [10] pared to alternative energy storage

Lithium battery for liquid cooled energy storage wholesaler in Turkmenistan

Heat Dissipation Analysis on the Liquid Cooling System Coupled The liquid-cooled thermal management system based on a flat heat pipe has a good thermal management effect on a

Containerized Energy Storage Solutions in Balkanabat Turkmenistan

Why Containerized Energy Storage Matters in Balkanabat Balkanabat, a hub for Turkmenistan''s oil and gas industries, faces unique energy challenges due to its remote infrastructure and

Turkmenistan liquid cooled energy storage lead-acid battery

Heat transfer characteristics of liquid cooling system for lithium J Energy Storage 2022; 45: 103767. Crossref. Google Scholar. 10. Jiaqiang E, Han D, Qiu A, et al. Orthogonal

Principles of liquid cooling pipeline design

3 days ago · This article will introduce the relevant knowledge of the important parts of the battery liquid cooling system, including the composition, selection

Liquid Cooled Battery Energy Storage Systems

Jan 28, 2024 · In the ever-evolving landscape of battery energy storage systems, the quest for efficiency, reliability, and longevity has led to the development of more innovative

Turkmenistan brand liquid-cooled energy storage battery

This innovative liquid cooling energy storage represents a significant leap in energy storage technology, offering unmatched advantages in terms of efficiency, versatility, and

Liquid Cooling Energy Storage: The Next Frontier in Energy Storage

Apr 5, 2025 · Liquid-cooled energy storage is becoming the new standard for large-scale deployment, combining precision temperature control with robust safety. As costs continue to

Why More and More Energy Storage Companies Are Choosing Liquid Cooling

Dec 13, 2024 · Explore the benefits of liquid cooling technology in energy storage systems. Learn how liquid cooling outperforms air cooling in terms of efficiency, stability, and noise reduction,

Energy Storage System Cooling

May 5, 2025 · Background Energy storage systems (ESS) have the power to impart flexibility to the electric grid and offer a back-up power source. Energy storage systems are vital when

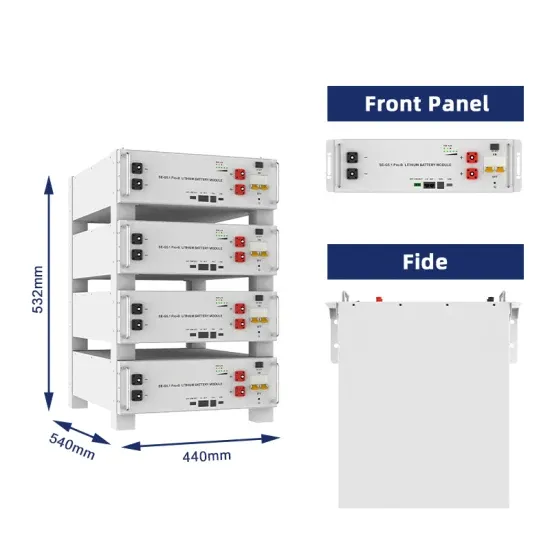

125kVA 232kWh Liquid-Cooled Energy Storage Cabinet | GSL ENERGY

As a leading energy storage cabinet manufacturer and supplier, GSL ENERGY offers fully integrated, factory-tested systems featuring lithium iron phosphate (LiFePO₄) batteries,

What are the manufacturers of liquid cooling energy storage?

Jan 30, 2024 · This innovative approach to energy storage offers multiple advantages, including improved thermal management, longer lifespan for components, and enhanced energy density

Liquid Cooling Energy Storage System | GSL Energy

Discover GSL Energy''s advanced liquid cooling energy storage systems for commercial and industrial applications. Scalable to 5MWh, certified by UL, CE,CEI and IEC. Improve energy

Liquid-Cooled Systems for Industrial and Commercial

Mar 1, 2024 · The integration of liquid cooling technology into industrial and commercial energy storage systems represents a significant stride toward efficiency, reliability, and sustainability.

5 FAQs about [Turkmenistan Liquid Cooling Energy Storage System Manufacturer]

What is a 5MWh liquid-cooling energy storage system?

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20’GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring harness, and more. And, the container offers a protective capability and serves as a transportable workspace for equipment operation.

What is a liquid cooling thermal management system?

The liquid cooling thermal management system for the energy storage cabin includes liquid cooling units, liquid cooling pipes, and coolant. The unit achieves cooling or heating of the coolant through thermal exchange. The coolant transports heat via thermal exchange with the cooling plates and the liquid cooling units.

Where is the liquid cooling unit located?

The liquid cooling unit, firefighting system, confluence chamber, and power distribution room are located at one end of the cabin, with the liquid cooling unit taking up the majority of the space. The liquid cooling piping runs along the bottom of the cabin, while the firefighting piping and wiring are laid out at the top.

How long is a 5MWh liquid-cooling energy storage cabin?

The layout project for the 5MWh liquid-cooling energy storage cabin is shown in Figure 1. The cabin length follows a non-standard 20’GP design (6684mm length × 2634mm width × 3008mm height). Inside, there are 12 battery clusters arranged back-to-back, each with an access door for equipment entry, installation, debugging, and maintenance.

What is a liquid cooling system?

This project’s liquid cooling system consists of primary, secondary, and tertiary pipelines, constructed by using factory prefabrication and on-site assembly within the cabin. The primary liquid cooling pipes utilize 304 stainless steel, whereas the secondary and tertiary pipes are made from PA12 nylon tubing.

Update Information

- Chile energy storage liquid cooling equipment manufacturer

- St George Liquid Cooling Energy Storage Cabinet Manufacturer

- Energy storage liquid cooling unit manufacturer

- Venezuela energy storage liquid cooling outdoor cabinet manufacturer

- Vaduz Liquid Cooling Energy Storage Cabinet Manufacturer

- Lithium battery site cabinet energy storage liquid cooling

- Liquid Cooling Energy Storage Container Price in Cebu Philippines

- Sana Liquid Cooling Energy Storage

- Liquid Cooling Energy Storage Monitoring

- Egypt Liquid Cooling Energy Storage Company

- Djibouti Energy Storage Liquid Cooling Container Factory Operation

- Photovoltaic power station energy storage 5MWH liquid cooling

- Liquid Cooling Energy Storage System Topology

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.