Multi-objective topology optimization design of liquid-based cooling

Request PDF | On Feb 1, 2025, Xiang-Wei Lin and others published Multi-objective topology optimization design of liquid-based cooling plate for 280 Ah prismatic energy storage battery

EGS215 Liquid Cooling Battery Energy Storage System

Feb 11, 2025 · The single 215kWh industrial and commercial liquid-cooled energy storage ba ery cabinet is an energy storage unit, consis ng of four liquid-cooled ba ery packs, a high-voltage

(PDF) Topology Optimization Design of Phase Change Liquid Cooling

May 20, 2025 · Topology optimization design flow of phase change liquid cooling coupling components. Topology optimization design flow of phase-change and liquid-cooled coupling

Liquid cooling design requirements for energy storage

A liquid air-based cooling system applied in data centers should not only meet the maximum cooling requirements of data center but also demonstrate good performance two types of

Liquid Cooling Energy Storage Cabinet Systems Topology

As renewable energy adoption accelerates globally, liquid cooling energy storage cabinet systems are emerging as a game-changer for industries demanding high efficiency and reliability. This

Structure optimization design and performance analysis of liquid

May 15, 2024 · Consequently, some researchers contend that liquid cooling represents a promising approach, as it demonstrates superior overall performance when compared

Frontiers | Optimization of liquid cooled heat

Jul 1, 2024 · Finally, the structure of the liquid cooling system for in vehicle energy storage batteries was optimized based on NSGA-II. The efficiency of NSGA-II

Performance analysis of new liquid cooling topology and its

Aug 1, 2022 · In addition, a performance analysis was performed on a data centre of 600 kW cooled with this topology for three heat rejection systems (mechanical cooling system using

Optimization of liquid cooling for prismatic battery with

Dec 20, 2023 · For maintenance of the batteries working at appropriate temperature, an effective thermal management system is required to handle the heat production during the operating

Liquid-cooled plate cooling channels design based on

Abstract: The thermal management of electric vehicles predominantly relies on liquid cooling. Recognizing the limitations of traditional serpentine liquid cold plate, characterized by poor

GUIDELINES FOR AUTHORS

Oct 28, 2024 · Compared to the other cooling methods, liquid cooling can utilize high thermal conductivity fluids such as ethanol and silicone oil to effectively manage battery temperatures.

Structure optimization design and performance analysis of liquid

May 15, 2024 · The structural design of liquid cooling plates represents a significant area of research within battery thermal management systems. In this study, we

Topology optimization design and thermofluid performance

Nov 23, 2024 · Liquid cooling with a cooling plate at its core, characterized by moderate cooling costs, is widely used in long-distance, high-safety electric vehicle cooling systems.

Thermal management performance and optimization of a hybrid system

Jul 15, 2025 · Thermal management performance and optimization of a hybrid system integrating liquid cooling and fin-enhanced phase change material for large-capacity energy storage

Liquid Cooling Energy Storage System Module Design

With the energy density increase of energy storage systems (ESSs), air cooling, as a traditional cooling method, limps along due to low efficiency in heat dissipation and inability in

Liquid Cooling Energy Storage System Module Design

In this paper, the thermal management design of large energy storage battery module in static application scenario is carried out, which provides a reference for the design High-power

Modeling and analysis of liquid-cooling thermal

Sep 1, 2023 · A self-developed thermal safety management system (TSMS), which can evaluate the cooling demand and safety state of batteries in real-time, is equipped with the energy

Topology optimization method to devise liquid-cooling plate

A numerical model of the sandwich-structured liquid cooling system (LCS) is then established to investigate the effects of discharge rate, channel height, and mass flow rate on the thermal

A liquid cooling plate based on topology optimization and

Nov 20, 2024 · As a critical component of the battery thermal management system (BTMS), the design and manufacture of the liquid cooling plate (LCP) has attracted great research interest

Liquid Cooling Energy Storage System Pipeline: The Future

Jul 15, 2020 · your energy storage system is throwing a pipeline party, but the heat keeps crashing it. That''s where liquid cooling energy storage system pipelines come in – the ultimate

5 MWh Liquid-cooling Energy Storage Container

Jun 19, 2024 · Increasing flexibility Flexible system topology for various scenarios, including the power generation side, grid side, and user side Modular design enables flexible capacity and

Multi-objective optimization of efficient liquid cooling-based

Oct 1, 2024 · Hence, implementing efficient thermal management systems to maintain LIB temperatures within optimal/acceptable ranges is crucial for the performance of energy storage

Examining the influence of number of inlets and outlets on the topology

Sep 1, 2024 · Abstract The trade-off between enhancing the thermal performance of battery liquid cooling plates and reducing their pumping power consumption remains an unresolved issue. In

Integrated cooling system with multiple operating modes for

Apr 15, 2025 · Aiming at the problem of insufficient energy saving potential of the existing energy storage liquid cooled air conditioning system, this paper integra

Multi-objective optimization of liquid cooling system for

Dec 1, 2024 · The battery thermal management system is critical for the lifespan and safety of lithium-ion batteries. This study presents the design of a liquid coo

A topology optimization-based-novel design and

Sep 1, 2024 · Findings demonstrate that the topology-optimized cold plate system with four inlets and two outlets exhibits optimal heat dissipation performance. Increases in coolant flow rate,

PowerCore Liquid-cooling Energy Storage Container 5 MWh

PowerCore Liquid-cooling Energy Storage Container 5 MWh Superb safety: Triple fire protection measures guarantee early detection, accurate spraying, and rapid fire suppression throughout

Liquid-cooled plate cooling channels design based on

Recognizing the limitations of traditional serpentine liquid cold plate, characterized by poor temperature uniformity and high voltage drop, this study explores the application of topology

Frontiers | Optimization of liquid cooled heat

Jul 1, 2024 · Liquid cooling technology, as a widely used thermal management method, is crucial for maintaining temperature stability and uniformity during

Exploration on the liquid-based energy storage battery system

Dec 1, 2024 · Lithium-ion batteries are increasingly employed for energy storage systems, yet their applications still face thermal instability and safety issues. This study aims to develop an

6 FAQs about [Liquid Cooling Energy Storage System Topology]

Does liquid cooled heat dissipation structure optimization improve vehicle mounted energy storage batteries?

The research outcomes indicated that the heat dissipation efficiency, reliability, and optimization speed of the liquid cooled heat dissipation structure optimization method for vehicle mounted energy storage batteries based on NSGA-II were 0.78, 0.76, 0.82, 0.86, and 0.79, respectively, which were higher than those of other methods.

How can a bi-objective topology optimize a battery cooling system?

To minimize both the volumetrically average temperature of the battery pack and the energy dissipation of the cooling system, a bi-objective topology optimization model is constructed, and so five cooling plates with different flowing-channel topologies are designed.

Can a liquid cooling structure effectively manage the heat generated by a battery?

Discussion: The proposed liquid cooling structure design can effectively manage and disperse the heat generated by the battery. This method provides a new idea for the optimization of the energy efficiency of the hybrid power system. This paper provides a new way for the efficient thermal management of the automotive power battery.

Can NSGA-II optimize the liquid cooling heat dissipation structure of vehicle mounted energy storage batteries?

Therefore, in response to these defects, the optimization design of the liquid cooling heat dissipation structure of vehicle mounted energy storage batteries is studied. An optimized design of the liquid cooling structure of vehicle mounted energy storage batteries based on NSGA-II is proposed.

Why is liquid cooling important?

Liquid cooling technology, as a widely used thermal management method, is crucial for maintaining temperature stability and uniformity during battery operation (Karimi et al., 2021). However, the design of liquid cooling and heat dissipation structures is quite complex and requires in-depth research and optimization to achieve optimal performance.

What is liquid cooling?

Liquid cooling with a cooling plate at its core, characterized by moderate cooling costs, is widely used in long-distance, high-safety electric vehicle cooling systems.

Update Information

- Huawei energy storage liquid cooling pack

- Which company in Hanoi does containerized liquid cooling energy storage

- Germany liquid cooling energy storage prices

- Energy storage air cooling and liquid cooling

- Chile energy storage liquid cooling equipment manufacturer

- Energy Storage Liquid Cooling 2025

- Energy Storage Battery Container Liquid Cooling System Manufacturers Ranking

- Venezuela energy storage liquid cooling outdoor cabinet manufacturer

- The energy storage period of the energy storage power station is 5MWH liquid cooling

- Djibouti Energy Storage Liquid Cooling Container Factory Operation

- Liquid Cooling Energy Storage Container Base Station

- Liquid cooling and air cooling structure design of energy storage system

- Key points of energy storage liquid cooling design

Solar Storage Container Market Growth

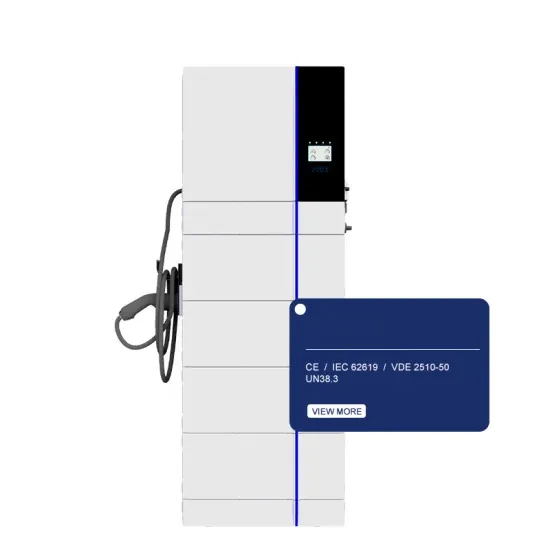

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.