Glass for polycrystalline photovoltaic panels

Polycrystalline silicon, or multicrystalline silicon, also called polysilicon, poly-Si, or Photovoltaic (PV) module assembly is material-demanding, and the cover glass constitutes a significant

Glass for polycrystalline photovoltaic panels

Photovoltaic (PV) module assembly is material-demanding, and the cover glass constitutes a significant proportion of the cost. Currently, 3-mm-thick glass is the predominant cover

Technological status of polycrystalline silicon thin-film solar

Dec 1, 2013 · Thin polycrystalline silicon (poly-Si) films on glass seem to be an attractive candidate for this because they feature the potential to combine the advantages of both thin

PHOTOVOLTAIC GLAZING IN BUILDINGS

Jul 15, 2022 · PV glazing is an innovative technology which apart from electricity production can reduce energy consumption in terms of cooling, heating and artificial lighting. It uses

Photovoltaic Glazing: Analysis of Thermal Behavior and

Jan 1, 2013 · Specifically in this research the thermal behavior of a BIPV glass product using c-Si by means of one-layer model is performed. The PV module temperature is then used to

Performance comparison of monocrystalline and polycrystalline

Nov 23, 2024 · Several companies are currently working on the production of aluminum-free glass-glass modules. Additionally, there are several possibilities for monocrystalline and

Performance Investigation of Tempered Glass-Based

Oct 31, 2021 · Performance Investigation of Tempered Glass-Based Monocrystalline and Polycrystalline Solar Photovoltaic Panels October 2021 International Journal of Photoenergy

High-efficiency polycrystalline solar cells via COC-SiO2 anti

Jan 1, 2025 · Solar glass with industrial porous SiO2 antireflection coating: measurements of photovoltaic module properties improvement and modelling of yearly energy yield gain

Photovoltaic solar cell technologies: analysing the state of

Mar 28, 2019 · Nearly all types of solar photovoltaic cells and technologies have developed dramatically, especially in the past 5 years. Here, we critically compare the different types of

Performance Investigation of Tempered Glass-Based

Oct 31, 2021 · This research aims at performing an experimental study to investigate the electrical performance of novel tempered glass-based PV panels using two different types of solar cells:

Crystalline Silicon Photovoltaic Modules, Crystalline Silicon

Crystalline photovoltaic glass refers to solar glass that incorporates traditional crystalline silicon photovoltaic (PV) technology. Unlike thin-film technologies like CdTe or CIGS, crystalline

Solar glass/Photovoltaic glass classification

Aug 27, 2019 · Here we illustrate the classification of the solar glass: Solar glass is divided into two categories, one is ultra-white rolled glass used in crystalline

Polycrystalline silicon on glass thin-film solar cells: A

Dec 1, 2013 · The paper presents a review of major features of the crystalline silicon on glass (CSG) technology, its achievements, limitations and challenges, and

Photovoltaic (PV) Cell Types | Monocrystalline,

5 days ago · The article provides an overview of the main types of photovoltaic (PV) cells, including monocrystalline, polycrystalline, and thin-film solar

Crystalline Silicon Technology

2 days ago · Crystalline silicon photovoltaic glass is recognized for its superior energy output, yielding more energy than amorphous silicon glass under direct sunlight. This technology is

A comparative study of mechanical crushing and

Sep 15, 2024 · Abstract With the rapid growth of the photovoltaic (PV) industry, efficient recovery and utilization of discarded polycrystalline silicon PV modules have attracted increasing

Polycrystalline Solar Panel: Definition, How it

Aug 12, 2024 · Polycrystalline, multicrystalline, or poly solar panels are a type of photovoltaic (PV) panel used to generate electricity from sunlight. They are

Glass-based Perovskite Photovoltaic|Glass that

Dec 20, 2024 · We aim to use it in various buildings as ''glass that generates electricity.'' Our perovskite solar cells have a power generation layer formed

Polycrystalline silicon on glass for thin-film solar cells

Jan 22, 2009 · Although most solar cell modules to date have been based on crystalline or polycrystalline wafers, these may be too material intensive and hence always too expensive to

Performance Investigation of Tempered Glass‐Based

Oct 31, 2021 · Solar photovoltaic (PV) converts sunlight into electricity and is an appropriate alternative to overcome the depletion of conventional fuels and global warming issues. The

Performance Investigation of Tempered Glass‐Based

Oct 31, 2021 · Performance Investigation of Tempered Glass-Based Monocrystalline and Polycrystalline Solar Photovoltaic Panels Department of Mechanical Engineering, Mehran

Method and apparatus for detaching glass form a mono

Process for separating glass from a photovoltaic panel laminate, the laminate comprising an encapsulating layer (3) of partly cross-linked ethylene vinyl acetate, EVA, and containing

6 FAQs about [Photovoltaic polycrystalline glass]

What is the efficiency of commercial crystalline silicon photovoltaic cells?

The commercial crystalline silicon photovoltaic cells exhibit an efficiency ranging from 12 % to 19 % .

How are polycrystalline solar cells made?

Polycrystalline solar or PV cells are produced by melting silicon crystals, pouring them into a square mold, and cooling them. This procedure generates numerous distinct crystals, resulting in a mottled, glistening visual effect perceived as blue by the human eye (Smith et al., 2021).

What is polycrystalline silicon?

Polycrystalline silicon, sometimes known as "polysilicon”, is a raw material used to produce monocrystalline or multi-crystalline silicon ingots. These ingots were then cut into wafers, processed into cells, and transformed into finished modules (Woodhouse et al., 2019).

What is a 3rd generation photovoltaic (PV) cell?

The third generation of photovoltaic (PV) cell technology is distinguished by incorporating advanced chemical compounds and applying nanocrystalline ‘films,’ quantum dots, dye-sensitized solar cells, and organic polymer-based solar cells. These advancements have led to improved performance and efficiency in solar energy conversion.

What is a monocrystalline solar cell?

Monocrystalline solar or PV cells are produced by manufacturers using high-quality Si crystals. The silicon unidirectionally aligns during production to create a singular sizable crystal. Due to their configuration, monocrystalline cells appear black to the human eye when interacting with light.

What is solar photovoltaics?

Solar photovoltaics (PV) is an essential part of renewable energy for the sustainable future. The worldwide installed capacity of solar panels recently exceeded 1TWp. The solar cells encounter around 30 % reflection losses at the surface of the front glass.

Update Information

- N Djamena polycrystalline photovoltaic module glass

- Are the glass of double-glass photovoltaic panels divided into upper and lower parts

- South Sudan photovoltaic glass Zhongshi standard

- New Zealand photovoltaic glass exports increase significantly

- Second photovoltaic glass production in Podgorica

- Cadmium ion photovoltaic glass

- Photovoltaic glass production plant in Mauritania

- Botswana Photovoltaic Glass Factory

- Is utg glass photovoltaic

- Photovoltaic glass factory in Tskhinvali

- Dili rooftop photovoltaic glass

- Latvian photovoltaic curved glass

- Circular equipment for photovoltaic glass factory

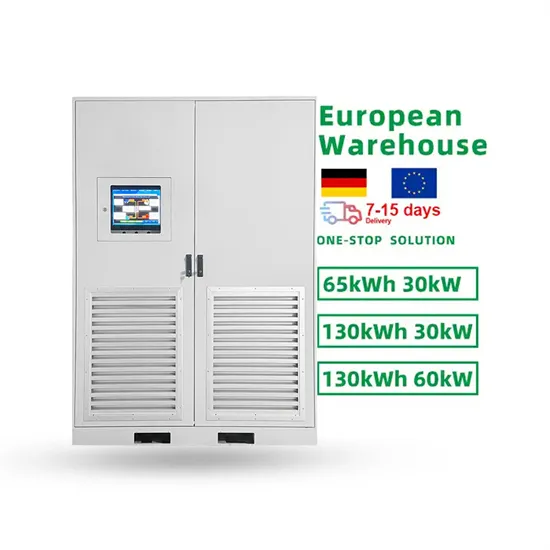

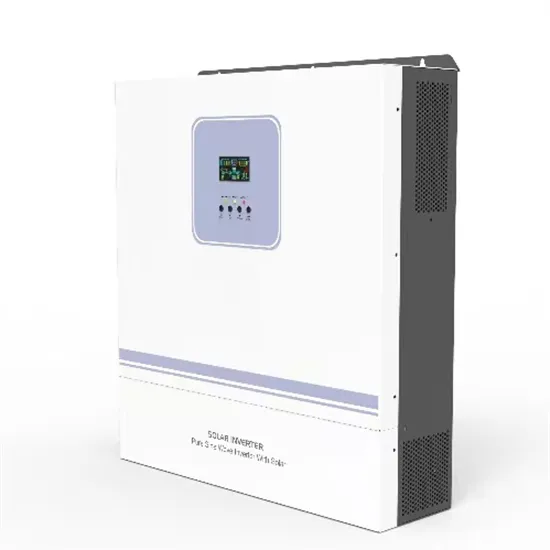

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.