HXD3C型机车车上总体布置

fHXD3C型机车总体布置 7. 控制电器柜外部(机车脱扣) fHXD3C型机车总体布置 8. 蓄电池柜(蓄电池QA61) fHXD3C型机车总体布置 9. 控制电器柜内部 fLOGO 结 束 f LOGO HXD3C型机车

HXD3型大功率交流传动电力机车运用保养说明书

HXD3型大功率交流传动电力机车运用保养说明书 13.2 机车控制监视系统 13.2.1 系统的构成 机车控制监视系统在硬件上主要由电源模块、逻辑运算控制部分、数字量输入/输出部分、模拟量

HXD3型电力机车低压电器柜的论文_百度文库

HXD3型电力机车低压电器柜的论文-1.1 HXD3型机车概述:今天,随着电力电子技术和计算机控制技术的发展,功率半导体电力变换技术得到迅速发展,电传动及控制技术进入了交流传动和网

HXD3型机车控制电器柜三项设备自动开关故障冗余设计方案

Aug 24, 2020 · 铁路货物运输交路调整后,HXD3型机车控制电器柜的部分自动开关使用方式发生了变化,最为突出的是在机车检修、整备及运用中控制电器柜的三项设备供电自动开关(无线

hxd3检修手册_18 -20电源柜、加热、端子柜

Nov 20, 2014 · HXD3 型大功率交流传动电力机车检修手册 18.蓄电池柜和 DC110V 电源装置 18.1 蓄电池柜 采用 DM170 型(2V/ 170Ah/10hr) 铅蓄电池配置在上下 2 层, 合计 49 个。 为使

HXD3型电力机车车顶电器设备的检修工艺设计.docx-原创力文档

May 6, 2021 · HXD3型电力机车车顶电器由DSA-200型受电弓、真空断路器、接地开关、高压连接器、高压隔离开关、高压电压互感器、原边电流互感器、避雷器和高压电缆组成。 本文重点

HXD3型运用参数及各部限度_百度文库

HXD3型运用参数及各部限度-hxd3型运用参数及各部限度公司各部门职责各部门岗位职责公司各部门岗位职责身体各部位分布图酒店各部门英文缩写各部门协调配合企业各部门职责营运部各部

Battery Cabinet | New and Used Battery Cabinets for Sale

Battery cabinets from diverse manufacturers APC, Toshiba, CC Power, Eaton, Powerware, Mitsubishi, Narada, and Salicru. We stock new and used battery cabinets in support of our

HXD3检修手册_18_-20电源柜、加热、端子柜

Jan 10, 2013 · HXD3 型大功率交流传动电力机车检修手册 18.蓄电池柜和 DC110V 电源装置 18.1 蓄电池柜 采用 DM170 型 2V 170Ah/10hr 铅蓄电池配置在上下 2 层 合计 49 个。 为使保养检

HXD3型电力机车主电路原理图讲解_哔哩哔哩_bilibili

Sep 20, 2020 · 请大家自行点餐, 视频播放量 4606、弹幕量 4、点赞数 80、投硬币枚数 12、收藏人数 97、转发人数 44, 视频作者 杂烩罐头, 作者简介 你好,欢迎你来到杂烩罐头的频道,能与你相遇我很荣幸同时深感幸运

What Are Battery Rack Cabinets and Why Are They Essential?

Jun 15, 2025 · Battery rack cabinets are modular enclosures designed to securely house and organize multiple batteries in industrial, telecom, or renewable energy systems. They optimize

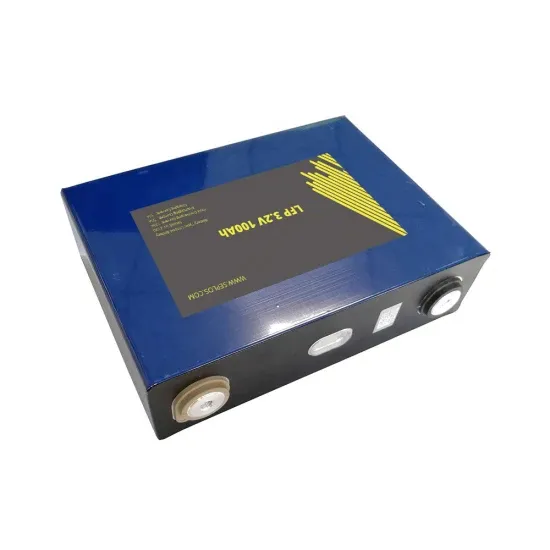

BATTERY CABINETS-Battery Cabinet-KEBOS POWER CO., LTD.-

Battery cabinets for all KEBOS UPS from 1KVA up to 1200KVA Power Range.The Battery cabinet is designed to house standard VRLA Batteries of capacity range from 17AH to 250AH.The

换电柜 (YT-ZF-6008-1)-Battery Swapping Cabinet (YT-ZF

Smart batteryidentification controls battery status in realtime.Waterproof/heat-proof/explosion-proof/fireproof protection desigr tomatic power off when fully charged, overvoltage,

HXD3-电气系统-讲课导论.ppt

Mar 24, 2017 · HXD3-电气系统-讲课导论.ppt,HXD3型交流传动货运电力机车 电气系统介绍 2007年2月8日 1.概述 HXD3型交流传动货运电力机车的主传动和辅助传动系统均采用了交流控制技

Update Information

- Battery cabinet storage capacity test

- Telecom 150ah battery cabinet

- How much does a photovoltaic energy storage battery cabinet weigh

- What is the charging temperature of the battery cabinet

- San Salvador outdoor communication battery cabinet battery replacement price

- How to control the current of battery cabinet

- Ouagadougou liquid-cooled energy storage cabinet system lithium battery pack

- New Energy Communication High Voltage Battery Cabinet

- New Energy 18 3 Battery Cabinet Price

- B32 Battery Cabinet Dimensions

- Lilongwe Remote New Energy Battery Cabinet

- New Energy Battery Cabinet Production Process

- Asuncion lithium battery cabinet manufacturer

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.