Lithium-ion Battery For Communication Energy Storage System

Aug 11, 2023 · Lithium-ion Battery For Communication Energy Storage System The lithium-ion battery is becoming more and more common in our daily lives. This new type of battery can

Maintenance and care of lead-acid battery packs for solar communication

The battery pack is an important component of the base station to achieve uninterrupted DC power supply, and its investment amount is b asic ally equivalent to that of the rack power

Application of energy storage lead-acid batteries in 5G base stations

As 5G base station construction process is accelerating, the As of the end of 2018, there was approximately 120,000 base stations in 31 provinces and cities across the country, and the

Substation Battery Systems Present & Future

Apr 29, 2024 · Designed to provide power backup for switches, circuit breakers, motors, monitors and communications equipment used for protecting electricity generation, distribution,

Tower base station energy storage battery

According to the requirement of power backup and energy storage of tower communication base station, combined with the current situation of decommissioned power battery, this paper

The Benefits of Maintenance-Free Lead Acid Batteries for Telecom Base

Telecom base stations are the backbone of modern communication infrastructure, requiring reliable and efficient power sources to operate continuously. In this context, maintenance-free

Optimal configuration of 5G base station energy storage

Feb 1, 2022 · The high-energy consumption and high construction density of 5G base stations have greatly increased the demand for backup energy storage batteries. To maximize overall

Whitepaper Pure Lead Batteries | Telecommunication

Apr 1, 2019 · Since the resistance-dependent influencing factors in sealed lead-acid batteries (VRLA), such as positive grid corrosion, dry-out (electrolyte) and sulfation, correlate with those

Battery for Communication Base Stations Market

The Battery for Communication Base Stations market can be segmented by battery type, including lithium-ion, lead acid, nickel cadmium, and others. Among these, lithium-ion batteries

What is the purpose of batteries at telecom base

Feb 10, 2025 · I believe that in the future, lead-acid batteries will continue to escort the development of the information age, so that we can enjoy more

MACHINE LEARNING AND IOT-BASED LI-ION BATTERY

Aug 11, 2023 · With the widespread popularity of new energy sources, the use of lithium-ion batteries instead of lead-acid batteries in 5G base stations has become a major trend.

Installation diagram of lead-acid battery for communication base

In this tutorial we will understand the Lead acid battery working, construction and applications, along with charging/discharging ratings, requirements and safety of Lead Acid Batteries.

Communication Base Station Lead-Acid Battery: Powering

In an era where lithium-ion dominates headlines, communication base station lead-acid batteries still power 68% of global telecom towers. But how long can this 150-year-old technology

Environmental feasibility of secondary use of electric vehicle

May 1, 2020 · Repurposing spent batteries in communication base stations (CBSs) is a promising option to dispose massive spent lithium-ion batteries (LIBs) from electric vehicles (EVs), yet

Lithium Battery for Communication Base Stations Market

The surge in demand for lithium batteries in communication base stations is primarily attributed to their superior performance characteristics compared to traditional lead-acid batteries.

Maintenance and care of lead-acid battery packs for solar communication

The battery pack is an important component of the base station to achieve uninterrupted DC power supply. Its investment is basically the same as that of the rack power supply equipment.

Lead-Acid Batteries in Telecommunications: Powering

Lead-acid batteries, with their reliability and well-established technology, play a pivotal role in ensuring uninterrupted power supply for telecommunications infrastructure. This article

5G base station application of lithium iron phosphate battery

Jan 19, 2021 5G base station application of lithium iron phosphate battery advantages rolling lead-acid batteries With the pilot and commercial use of 5G systems, the large power consumption

6 FAQs about [Construction of lead-acid battery transmission for communication base stations]

How does a lead acid battery work?

Lead acid battery is a type of rechargeable battery that uses lead plates and sulphuric acid to store and produce electrical energy. It works through a chemical reaction between the lead and electrolyte, which creates electricity when connected to a load. What are the characteristics of lead acid battery?

What are lead acid batteries used for?

Lead Acid batteries are used for variety of application such as: For petrol motor car starting and ignition. As a source of power supply in telephone exchange, laboratories and broadcasting stations. For local lighting of generating and substations during odd times and break down. For starting rotary converters in substations.

What happens when lead plates are placed in acid?

When the lead plates are placed in the acid, a chemical reaction takes place, which produces electricity. This process can be reversed to recharge the battery. When several battery cells are joined together in series, parallel or a mix of both, they form a complete battery.

What type of electrolyte is used in a lead-acid battery?

Electrolyte: Electrolyte used in a lead-acid battery is a dilute sulphuric acid solution. It is usually a mix of three parts water and one part sulphuric acid. Container: Plates and electrolyte are placed in a container which may be made of vulcanised rubber or moulded hard rubber, ceramic, glass or celluloid. Container is sealed at the top.

What is the difference between plate and separator in a lead acid cell?

Plates: Plates of a lead acid cell are made of antimonial lead alloy grid. The grids used for both positive and negative plates have the same design. Separator: The separators are thin sheets of a porous material which are place between +ve and -ve plates to prevent internal short circuit of the +ve and -ve plates.

What is the difference between separator and electrolyte in a lead-acid battery?

Separator: The separators are thin sheets of a porous material which are place between +ve and -ve plates to prevent internal short circuit of the +ve and -ve plates. Electrolyte: Electrolyte used in a lead-acid battery is a dilute sulphuric acid solution. It is usually a mix of three parts water and one part sulphuric acid.

Update Information

- Are there any lead-acid battery service providers for communication base stations in Athens

- Which company does the lead-acid battery for communication base stations belong to

- Research direction of lithium-ion battery construction for communication base stations

- Brussels communication base station flow battery construction company

- Maintenance of battery energy storage system for integrated communication base stations in France

- Record of the construction of supercapacitors for Somalia communication base stations

- South Korea 5g communication base station battery energy storage system construction ESS system

- Development prospects of liquid flow battery equipment for communication base stations

- Construction plan for solar panels for communication base stations

- Cambodia Communication Base Station Flow Battery Construction Regulations

- Tokyo 5g communication base station lead-acid battery

- Victoria accelerates the construction of 5G communication base stations and wind power

- Battery energy storage system for communication base stations is energy-saving and is issuing bonds

Solar Storage Container Market Growth

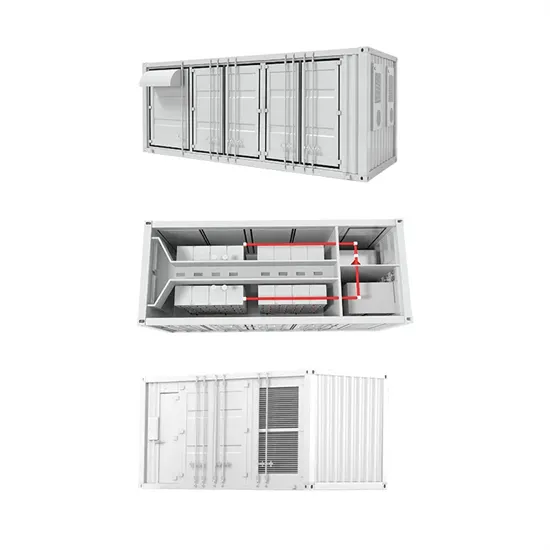

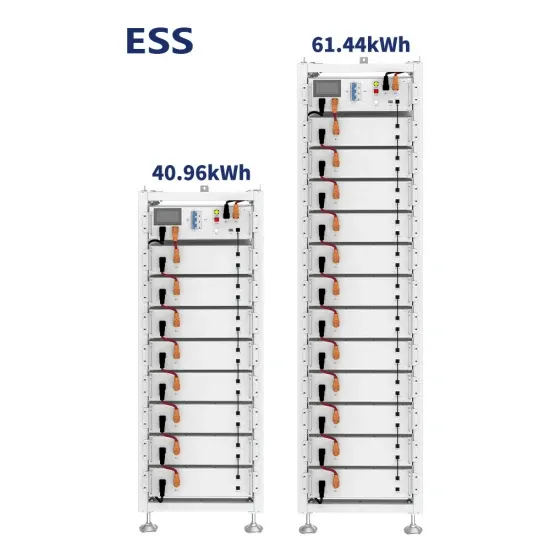

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

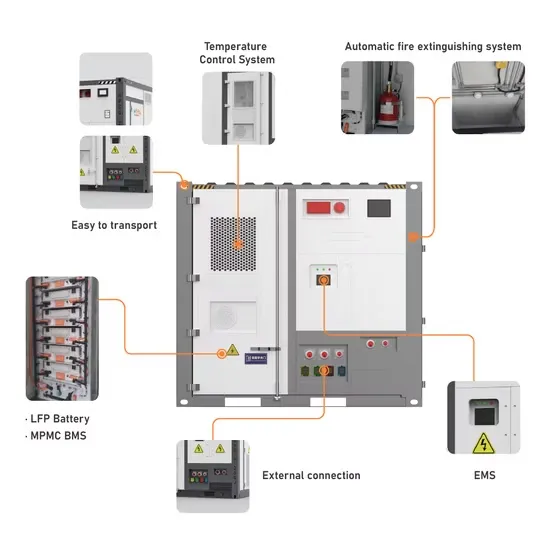

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.