(PDF) State-of-Charge Uncertainty of Lithium-Ion Battery

Feb 14, 2019 · Accurate state-of-charge (SOC) estimation of lithium-ion battery packs is technically challenging because of the cell-to-cell variability due to the manufacturing

Simulation of abuse tolerance of lithium-ion battery packs

Jan 1, 2007 · The thermal abuse tolerance of battery packs is estimated based on the exothermic behavior of a single cell and an energy balance than accounts for radiative, conductive, and

Fault Tolerance Optimization of a Lithium Battery Pack

Sep 9, 2022 · In this paper, a simulation method for a typical air-cooled lithium battery pack having a damaged unit was studied. Also, a fault tolerance optimization method for the lithium

Simulation of abuse tolerance of lithium-ion battery packs

Jan 1, 2007 · This short communication presents a new approach for estimating the thermal abuse tolerance of lithium-ion battery packs based on the behavior of individual cells.

doi:10.1016/j.jpowsour.2006.10.013

May 25, 2018 · This short communication presents a new approach for estimating the thermal abuse tolerance of lithium-ion battery packs based on the behavior of individual cells.

Fault Tolerance Optimization of a Lithium Battery Pack

Aug 23, 2022 · As a kind of green and sustainable technology, electric vehicles are continuously highlighted for solving the significant problems of energy and air pollution. In this paper, fault

How To Balance A Lithium Batteries: Top and

Oct 3, 2022 · A balanced battery pack is critical to getting the most capacity out of your pack, read along to learn how to top and bottom balance a lithium battery

Multi-Physics Model of Lithium-Ion Battery and Battery Pack

Jun 4, 2021 · Based upon previous work that has successfully developed multi-scale models (i.e., electrochemical and thermal-mechanical models) for modeling the thermal runaway inside

Fault Tolerance Optimization of a Lithium Battery Pack

ABSTRACT: As a kind of green and sustainable technology, electric vehicles are continuously highlighted for solving the significantproblems of energy and air pollution. In this paper, fault

Strings, Parallel Cells, and Parallel Strings

Feb 15, 2016 · Strings, Parallel Cells, and Parallel Strings Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is

Thermal fault detection of lithium-ion battery packs through

Apr 28, 2025 · Battery packs develop faults over time, many of which are difficult to detect early. For instance, cooling system blockages raises temperatures but may not trigger alerts until

Simulation of abuse tolerance of lithium-ion battery packs

Jan 1, 2007 · A simple approach for using accelerating rate calorimetry data to simulate the thermal abuse resistance of battery packs is described. The thermal abuse tolerance of battery

Presentation Title Here

5 days ago · More advanced battery packs may need additional features such as cell balancing, high side FET drive to allow communication with protections triggered, battery monitoring for

How does lithium battery BMS determine the

May 1, 2025 · This article will explore the functions, working principles, application areas, future development trends, and challenges of lithium battery BMS in

How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Harm of Lithium Battery Inconsistency to PACK and

Inconsistency in lithium battery parameters mainly refers to variations in capacity, internal resistance, and open-circuit voltage. Using cells with inconsistent parameters together can

6 FAQs about [Lithium battery pack has tolerance]

How safe is a Li-ion battery pack?

Due to the coupling effect of multiple cells, the thermal safety of a Li-ion battery pack is different from that of a single cell. Previous studies usually assumed the same loads and model parameters to facilitate calculations [19, 22].

What are lithium-ion battery packs?

Lithium-ion battery packs (LIBPs) play a crucial role in electrified transportation systems. The cost of LIBPs has a substantial impact on the manufacturing expenses of electric vehicles (EVs), typically representing 25% of the total EV production cost 1, and 75% of the powertrain cost 2.

Which battery pack should be used in a multiphysics model?

Model parameters To verify the feasibility of the proposed method, a typical 4 × 6 parallel–series battery pack composed of NCR 18,650-B is employed considering the trade-offs between the sufficient coverage of simulation samples and the accuracy and complexity of the multiphysics model.

What is the thermal safety risk of a battery pack?

Therefore, the thermal safety risk of a battery pack can be evaluated based on the SSI model . In this study, the critical ambient temperature Tam,cr and critical operating power Pb,cr are taken as the physical quantities of strength to characterize the TR of the electrochemical exothermic system.

Can a Li-ion battery be overcharged?

The main challenge in charging a Li-Ion battery is to realize the battery's full capacity without overcharging it, which could result in catastrophic failure. There is little room for error, only ±1%. Overcharging by more than +1% could result in battery failure, but undercharging by more than 1% results in reduced capacity.

How to evaluate the safety risk of a battery pack?

Safety risk evaluation of battery pack To evaluate the safety risk of the battery pack, the critical ambient temperature and operating power need to be coupled for thermal safety analysis. Based on the randomness and distribution types of parameters in , the Monte Carlo method is used for combined sampling.

Update Information

- Saudi Arabia lithium battery pack 3D configuration

- Italian Milan 36v lithium battery pack

- Tuvalu energy storage lithium battery pack customization

- American large monomer lithium battery pack

- Solar Lithium Battery Pack

- Dxhc01 lithium battery pack

- Juba lithium iron phosphate battery pack

- Masai 220V lithium battery pack

- Indian lithium battery pack processing

- Lithium battery pack traders

- Zimbabwe explosion-proof lithium battery pack

- Lithium titanate battery 12 volt battery pack

- Maputo lithium battery pack

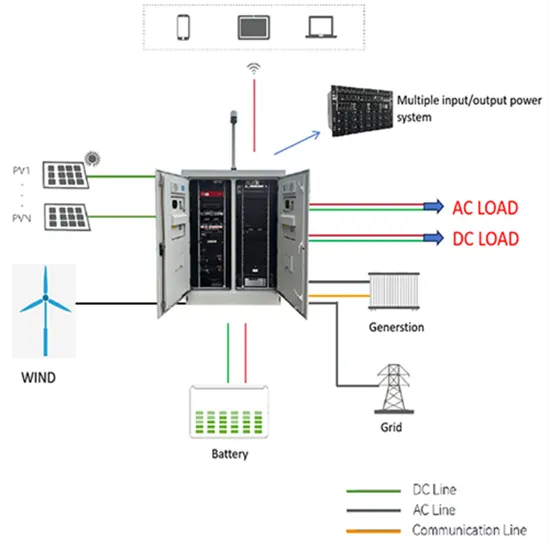

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.