Does a solar inverter use a lot of electricity

Mar 1, 2025 · Solar inverters are crucial components of solar energy systems as they convert the direct current (DC) electricity produced by solar panels into alternating current (AC) electricity,

Understanding Inverter Power Consumption: Do Inverters

Mar 12, 2025 · Most inverters today consume minimal power when not actively converting electricity. Typically, this is in the range of 1 to 15 watts, depending on the inverter model and

Idle ''no load'' Consumption: Specs vs Your Personal Observation

Dec 10, 2019 · The alternator was controlled by the inverter and produced about 30-40 volts AC phase to phase and this power was rectified within the inverter which provided up tp 100 amps

Understanding How Power Inverters Impact Car Batteries:

Jul 26, 2024 · Discover the truth about power inverters and car batteries! Learn that inverters do not drain car batteries continuously, but usage depends on connected devices. Unveil vital tips

How Many Watts Does a Mini Split Use?

Jun 3, 2025 · Note: This data is based on 272 popular mini splits on the market. How many watts does a 3 ton mini split use? A 3 ton mini split uses 3,330 to 4,250 watts. Did you know that if

Inverter Air Conditioner Energy Calculator (Cost and kWh

Aug 6, 2025 · Calculate the energy consumption and usage costs of a Inverter Air conditioner. Learn about its cost in dollars of usage and money-saving tips to reduce bills.

How does a 12V to 220V Inverter Work?

Jun 11, 2022 · PowMr Store''s inverter converts DC power from a 12V battery system to AC power, which can power your home electrical equipment properly and can run a variety of 220V

48V Inverter: The Ultimate Guide to Efficient and Scalable

May 19, 2025 · Unlock efficient power solutions with a 48V inverter—perfect for solar, off-grid, and backup systems. Learn how to choose the best one for your needs now!

12v led lights vs 220 led lights | DIY Solar Power Forum

May 6, 2020 · does anybody knows the difference in energy consumption of 12 v volts vs 220 v lights?, for examplo if i have a 12v 16 watts led, and a 220v 16 watts led, will they consume the

How much energy does an inverter consume?

Jul 27, 2025 · Briefly: Don''t worry: a good inverter will cost you virtually no extra power and is designed to deliver maximum efficiency. An inverter itself consumes a minimal amount of

Inverter Usage Calculator & Formula Online Calculator Ultra

Oct 3, 2024 · The Inverter Usage Calculator helps users to determine the energy consumption of their inverter systems, which is crucial for managing electricity bills and assessing power needs.

6 FAQs about [Does a 220v inverter consume electricity ]

Do inverters consume a lot of power?

While inverters are essential for off-grid living or during power outages, it's important to be mindful of their power consumption, particularly when they are in standby mode. In this article, we will explore the no-load current draw of inverters, the amperage they draw, and provide some practical advice on reducing standby power consumption. 1.

How much power does an inverter use?

The average draw from the batteries when an inverter is turned on with no load attached depends on the efficiency of the inverter and its standby power consumption. In general, the standby power consumption of most inverters is relatively low, typically less than 1% of their rated power output.

How much power does a 1000W inverter use?

In general, the standby power consumption of most inverters is relatively low, typically less than 1% of their rated power output. For a 1000W inverter, the average idle power consumption could be around 10-20 watts, while for a 2000W inverter, it could be around 20-40 watts.

Do inverters consume a lot of energy during a power outage?

Well, during extreme power outages, you will have to use your inverter more than usual, which will increase your energy consumption. Moreover, you can only limit your consumption if your downtime is not that much, and you do not have to discharge your inverter’s battery.

What is a power inverter & how does it work?

Inverters are essential components of many power backup systems, helping to convert DC power stored in batteries into AC power for household or commercial use. Understanding how much energy an inverter uses helps to manage power costs and ensure efficient energy usage.

How much power does a 12 volt inverter use?

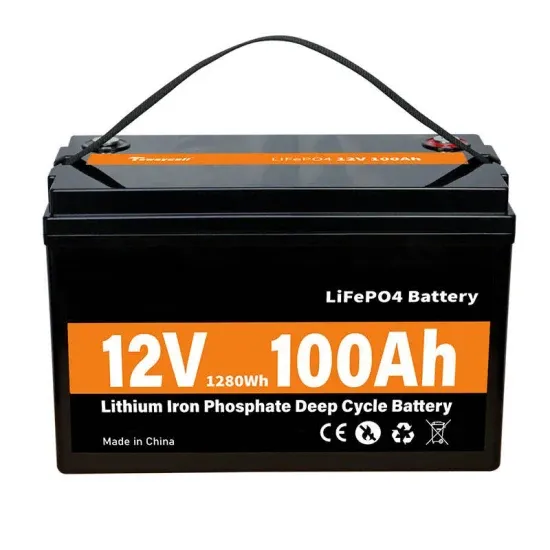

Power conversion losses from converting 12v DC battery power to 230v AC mains power in an inverter uses about 10% more power than the actual appliance draws, so expect around a 1540w draw from the battery (1400w x 1.1 = 1540w). Assuming a cup of coffee takes about a minute to make: 1540w / 12 volts = 128 Amps

Update Information

- 1 point 5 degrees of electricity inverter into 220v

- Does the 220V inverter cost electricity

- Does a 24 volt inverter consume electricity

- Huawei 72v to 220v inverter

- Ghana inverter 220V assembly

- Single-phase 220V inverter to UPS inverter

- Bastel 50kw single phase 220v inverter

- Tanzania inverter 48v to 220v inverter

- 60v-72v to 220v inverter

- Afghanistan lithium battery inverter 12v to 220v

- Harare 96v to 220v inverter brand

- Wholesale 220v solar inverter in Mombasa

- 24v inverter 220v brand name

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.