12V Inverter vs 24V Inverter — What Is The Difference

Choosing between a 12V and 24V inverter impacts efficiency, performance, and device compatibility. This article will explore the differences between 12v inverter vs 24v inverter,

Inverter loss: 12-volt vs 120-volt energy usage

Dec 27, 2024 · Inverter loss: 12-volt vs 120-volt energy usage As promised here''s my battery usage test comparing the run time of a Vitrifrigo fridge/freezer on

How much power does an Inverter use just sitting there idling?

Oct 30, 2020 · Hello, Quick question. I have a 24V 3000W pure sine wave inverter powering two 15A circuits. The inverter itself uses about 30W running a 500W load. There are some times

How Much Energy Does A Solar Inverter Use

Mar 30, 2025 · To calculate the power usage of your inverter, you can use a simple method: for 12-volt inverters, divide the connected load by 10; for 24-volt, divide by 20. Idle power

What does a power inverter do, and what can I use one for?

The inverter draws its power from a 12 Volt battery (preferably deep-cycle), or several batteries wired in parallel. The battery will need to be recharged as the power is drawn out of it by the

How much electricity does a mini split use? A

Feb 11, 2024 · But in general, the electricity consumption of air conditioners and heat pumps is still known to be relatively high. So, the question remains, How

Does a 24V inverter consume the same amount

Aug 16, 2015 · In parallel current adds but voltage doesn''t. But that doesn''t really answer my question about the energy consumption of a given setup. Let''s use

Unveiling the energy efficiency secret: how much electricity does

Jan 17, 2025 · Inverter heat pumps have emerged as an energy-efficient alternative to traditional heating and cooling systems. Understanding their electricity consumption is crucial for

Idle ''no load'' Consumption: Specs vs Your Personal Observation

Dec 10, 2019 · With time--if this thread gains traction--it could be a useful resource for those shopping for inverters, and help us calibrate our expectations. At a minimum report (1)

How much power does an inverter battery have

For 24-volt inverters,it is 10 %. The battery capacity for a 12-volt Mass Sine 12/1200,for instance,is 240 Ah,while a 24-volt Mass Sine 24/1500 inverter would require at least 150 Ah. How much

How Much Power an Inverter Draws with No Load

To find out how much power an inverter draws without any load, multiply the battery voltage by the inverter no load current draw. A 1000 watt 24V inverter with a 0.4 no load current has a

Understanding Inverter Power Consumption: Do Inverters

Mar 12, 2025 · In today''s energy-conscious world, many homeowners and businesses are increasingly turning to energy-efficient solutions, and inverters have become an essential part

6 FAQs about [Does a 24 volt inverter consume electricity ]

How much power does a 24V inverter draw?

To find out how much power an inverter draws without any load, multiply the battery voltage by the inverter no load current draw. A 1000 watt 24V inverter with a 0.4 no load current has a power consumption of 9.6 watts. 24V x 0.4 = 9.6 watts If you want to figure out the no load current in amps, divide the watts consumption by the battery voltage.

Is a 24V inverter better than a battery?

A 24V inverter, on the other hand, can handle higher power loads, often up to 3,000 watts or more, with a more efficient current draw. Because the higher voltage allows for less current to be drawn from the battery, it results in lower energy losses and increased efficiency.

How much battery does a 24 volt inverter use?

For 24-volt inverters, it is 10 %. The battery capacity for a 12-volt Mass Sine 12/1200, for instance, is 240 Ah, while a 24-volt Mass Sine 24/1500 inverter would require at least 150 Ah. The indicated battery capacity is only for the inverter. The capacity required for other loads should be added to it. How much power does an inverter consume?

Should I buy a 24V inverter?

24V Inverters: More efficient in larger systems since they require lower current, reducing energy loss and wire size. This can save energy, extend battery life, and use smaller components. However, the choice isn’t always simple. It depends on your system’s size, the quality of the inverter, and your power needs.

Are 24V inverters more efficient than 12V?

In general, 24V inverters are more efficient than their 12V counterparts, especially for larger systems. The efficiency difference becomes more noticeable as you increase the power demand of the system. 12V Inverters: Generally less efficient, especially as the power demand increases. You may experience energy loss due to higher current draw.

How many amps does a 24V inverter use?

If the voltage of the inverter is increased to 24V (assuming the losses remain the same at 2 watts), the input current to the converter will be: 0.5 amps. This is calculated as 12 watts (power) / 24 volts (voltage). If a 24V battery is made up of two 12V batteries in series, it makes no difference whatsoever.

Update Information

- Selling 24 volt inverter

- 24 volt simple inverter

- 24 volt 5500w inverter

- Is the 24 volt power inverter easy to use

- 24 volt inverter 2500m

- 24 volt inverter with 12 volt

- Can photovoltaic panels generate electricity for use with 24 volt motors

- Does a 220v inverter consume electricity

- Inverter 24 volt and 12 volt

- Inverter 12v upgrade 24 volt

- 12 volt generator drives inverter

- 18 volt solar panel inverter

- Do 5G base stations consume extra electricity

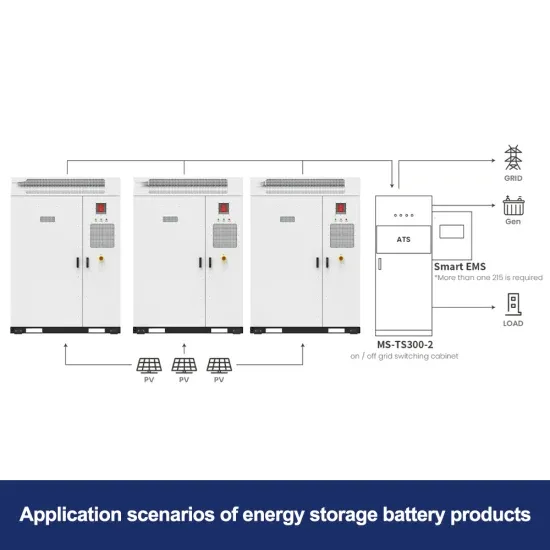

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.