Solar Photovoltaic Glass: Classification and Applications

Jun 26, 2024 · Depending on their properties and manufacturing methods, photovoltaic glass can be categorized into three main types: cover plates for flat-panel solar cells, usually made of

Global Photovoltaic Conductive Glass Market Research

The global market for Photovoltaic Conductive Glass was valued at US$ million in the year 2024 and is projected to reach a revised size of US$ million by 2031, growing at a CAGR of %during

Photovoltaic Conductive Glass Market Report | Global

Transparent Conductive Oxide (TCO) glass is renowned for its ability to transmit visible light while conducting electricity, making it an essential component in the manufacturing of solar panels.

Global Photovoltaic Conductive Glass Supply, Demand and

There are many coating materials and processes for transparent conductive oxides, which are continuously screened through scientific research, mainly including ITO coated glass, SnO2

Photovoltaic Conductive Glass Market Size, Predictions:

Apr 27, 2024 · The photovoltaic conductive glass market is highly competitive with a number of key players vying for market share. These players are constantly engaging in research and

United States Photovoltaic Conductive Glass Market Analysis

The United States Photovoltaic Conductive Glass Market is expected to witness robust growth over the forecast period from 2024 to 2031, driven by technological advancements, rising

Physical Properties and Applications of FTO Conductive Glass

In the photovoltaic field, FTO coated glass is widely used as a transparent conductive electrode in perovskite solar cells and CIGS thin-film cells. Its high light transmittance and low resistivity

United States Photovoltaic Conductive Glass Market By

Aug 14, 2024 · The photovoltaic conductive glass market is impacted by global economic conditions in terms of investment in renewable energy, government subsidies, and consumer

Photovoltaic Conductive Glass Market Share Industry Size

Chapter 6: Sales of Photovoltaic Conductive Glass in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · Photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by laminating into solar cells, and has relevant

Singapore Photovoltaic Conductive Glass Market Size 2026

Jul 31, 2025 · Singapore Photovoltaic Conductive Glass Market size was valued at USD xx Billion in 2024 and is forecasted to grow at a CAGR of xx% from 2026 to 2033, reaching USD xx

上海耀皮玻璃集团股份有限公司

1. High transmittance: Absorb more sunlight and improve photoelectric conversion efficiency. 2. Conductivity: TCO conductive coating has a very low electric resistance, and can be adjusted

Photovoltaic Conductive Glass Market Size, Competitive

Discover comprehensive analysis on the Photovoltaic Conductive Glass Market, expected to grow from USD 3.5 billion in 2024 to USD 10.2 billion by 2033 at a CAGR of 12.5%. Uncover critical

6 FAQs about [St Johns Photovoltaic Conductive Glass]

What is Photovoltaic Glass?

Photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by laminating into solar cells, and has relevant current extraction devices and cables. The glass used in photovoltaic power generation is not ordinary glass, but TCO conductive glass.

What is electrically conductive glass?

Increasingly, electrically conductive glass is used in photovoltaic modules as the front contact of the solar cell, to form a system which generates a direct electrical current. The United States and the European Union in particular, are encouraging the production of renewable energy.

Which glass is used in photovoltaic power generation?

The glass used in photovoltaic power generation is not ordinary glass, but TCO conductive glass. HHG is a professional glass manufacturer and glass solution provider include range of tempered glass, laminated glass, textured glass and etched glass.

What raw materials are used in Photovoltaic Glass production?

The raw materials used in the production of photovoltaic glass raw materials include soda ash, quartz sand, feldspar, dolomite, limestone, mirabilite, etc. Quartz sand and soda ash are not only the main components in material input, but also the two types of raw materials that have a significant impact on material costs.

Why is Solar Photovoltaic Glass so popular?

With global attention on environmental protection and energy efficiency steadily rising, the demand for solar photovoltaic glass in both commercial and residential construction sectors has significantly increased. The desire to reduce energy costs and carbon footprint has driven the widespread adoption of solar photovoltaic glass.

What is the production process of Photovoltaic Glass?

Production process of photovoltaic glass The deep processing process of photovoltaic glass involves two steps: tempering and coating. The original sheet is ground and then tempered to obtain tempered sheets, or tempered and coated to obtain coated sheets for component packaging.

Update Information

- St Johns Curtain Wall Photovoltaic Company

- Conductive glass for photovoltaic modules

- Photovoltaic conductive glass manufacturers

- St Johns Photovoltaic Energy Storage Battery Cabinet System Manufacturer

- Greece a benefit photovoltaic conductive glass

- St Johns Photovoltaic Panel Manufacturer

- San Marino Photovoltaic Glass Panel Glass Demand

- Photovoltaic glass substrate

- How many millimeters does photovoltaic glass use

- Photovoltaic glass highway

- Canberra Photovoltaic Glass Factory

- New Zealand photovoltaic glass exports increase significantly

- Photovoltaic glass curtain wall system in Monterrey Mexico

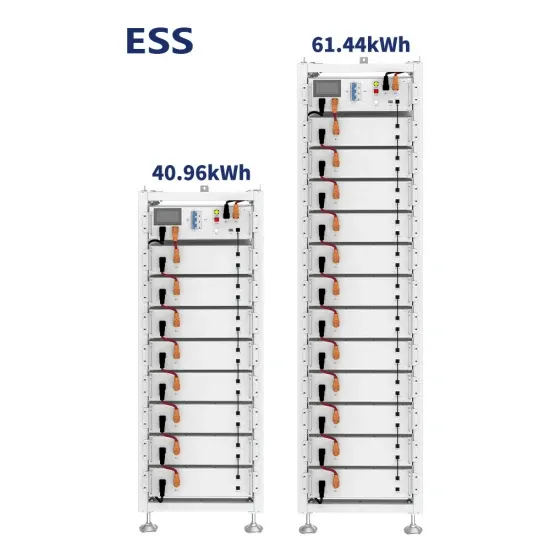

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.