How to adjust the flatness of photovoltaic panels during

The optimal tilt angle of photovoltaic solar panels is that the surface of the solar panel faces the Sun perpendicularly. However,the angle of incidence of solar radiation varies during the day

Photovoltaic panel flatness measurement standards

Basic Understanding of IEC Standard Testing for Photovoltaic Solar Panels Below are some of the most common solar panel testing standards and certifications to look for when comparing

THE INCREDIBLE ULCS: HOW ULTRA LOW-COST SOLAR

elevate solar photovoltaics (PV) in Australia''s national priorities by outlining the benefits that extremely cheap solar could unlock, and communicate key barriers and innovation priorities for

Flatness specification of photovoltaic panels

Parameters of photovoltaic panels (PVPs) is necessary for modeling and analysis of solar power systems. The best and the median values of the main 16 parameters among 1300 PVPs were

How to design a PV plant with topography

Dec 2, 2021 · Utility-scale solar photovoltaic (PV) plants have typically been built on flat, open spaces with minimal variation in the land''s topography. Making

Photovoltaic panel angle flatness hazards

From the above analysis and discussion,one may conclude the following: 1. The energy collected by a flat solar collector or PV solar panel over an entire year is not significantly impactedby the

FLATNESS TESTING DEVICE FOR SOLAR PANEL INSTALLATION OF PHOTOVOLTAIC

A flatness testing device for solar panel installation of a photovoltaic system, comprising: a base part, a conveying part, a testing part, and a material transport part.

Photovoltaic panel flatness measurement standards

The standard test condition for a photovoltaic solar panel or module is defined as being 1000 W/m 2 (1 kW/m 2) of full solar irradiance when the panel and cells are at a standard ambient

Physical Properties of Glass and the Requirements for

Feb 16, 2011 · NREL Photovoltaic Module Reliability Workshop February 16, 2011 Photovoltaic Glass Technologies Corning has a long history of life-changing innovations Glass envelope for

A Comparative Analysis of the Performance of Flat and

Aug 5, 2024 · Overall, the flat panel exhibited better photovoltaic performance than the slanting panel. Key Words: Solar Panel, PV, Mono-crystalline, voltage-current (I-V) characteristics,

Nonlinear flatness control applied for energy management of PV

Oct 31, 2013 · This paper presents the hybridization of photovoltaic (PV) panels considered as the main source, with lead-acid batteries and supercapacitors used as storage sy

How to check the flatness of photovoltaic panels

Your multimeter is your best friend when testing solar panels. You can use it to check: 1. Open circuit voltage (Voc) 2. Short circuit current (Isc) 3. Current at max power (Imp) Here''s how:

WO/2022/021493 FLATNESS TESTING DEVICE FOR SOLAR

Aug 17, 2020 · In the present invention, the testing assembly (2) is designed to test the flatness of solar panels, thereby avoiding the power generation efficiency of an installed power generation

Tube cross-section flatness optimization to enhance the

Oct 10, 2024 · Photovoltaic panels (PV), convert solar radiation into electricity through the photovoltaic effect. PV panels are a vital component of solar energy systems and play a crucial

Tube cross-section flatness optimization to enhance the

Oct 10, 2024 · In optimized mode, PV surface temperature decreases up to 6 % related to non-flattened tubes. Photovoltaic (PV) systems have emerged as a crucial technology in

How to check the flatness of photovoltaic panels

How to check the flatness of photovoltaic panels Comprehensive inspection report detailing modules tested and findings for each module. Explanation of most risk associated with the

WO/2022/021493 FLATNESS TESTING DEVICE FOR SOLAR

Aug 17, 2020 · A flatness testing device for solar panel installation of a photovoltaic system, comprising: a base part, a conveying part, a testing part, and a material transport part.

Mechanical characteristics of a new type of cable-supported

Sep 15, 2021 · Cable-supported photovoltaic (PV) modules have been proposed to replace traditional beam-supported PV modules. The new system uses suspension cables to bear the

Flatness specification of photovoltaic panels

Flatness specification of photovoltaic panels What are the parameters of photovoltaic panels (PVPS)? Parameters of photovoltaic panels (PVPs) is necessary for modeling and analysis of

What to Do If Photovoltaic Panel Components Aren''t Flat:

Why Flatness Matters for Solar Panel Performance Did you know that even a 5-degree tilt deviation in photovoltaic (PV) panels can reduce energy output by up to 12%? A 2024 Solar

Flatness specification of photovoltaic panels

not listed at all. 72-cell solar panel size. The dimensions of 72-cell solar panels are a follows: 77 ailable solar energy into useful electricity. That is specifications for solar PV installations 1.

Update Information

- Efficacy of Micro Solar Photovoltaic Panels

- Photovoltaic solar panels on rooftops in Ireland

- South Ossetia solar flexible photovoltaic panels

- China-Africa solar panels and photovoltaic panels manufacturers direct sales

- Solar photovoltaic panels in Gabon

- Solar photovoltaic panels are non-standard

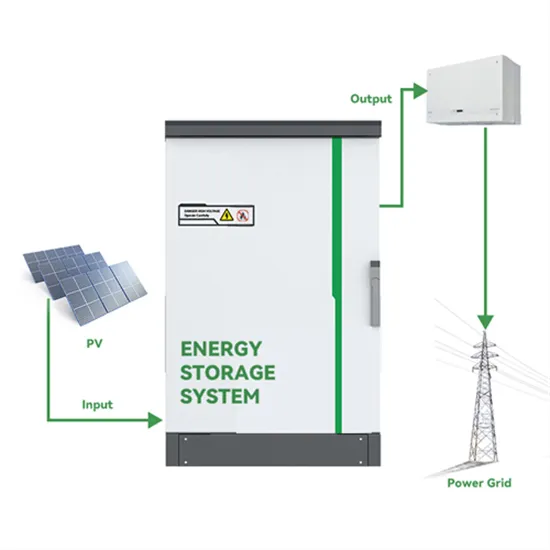

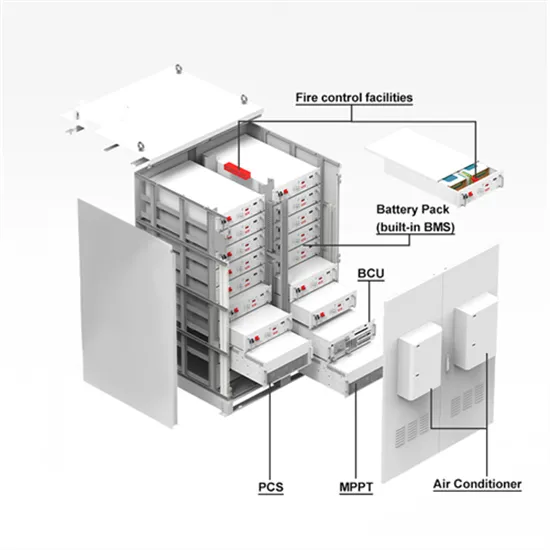

- Solar energy storage cabinet photovoltaic panels

- Ankara s latest solar photovoltaic panels

- Which factory does Boston solar photovoltaic panels come from

- Sana a Professional Solar Photovoltaic Panels

- Manufacturers sell brand new photovoltaic solar panels

- Beirut Photovoltaic Panels Greenhouse Solar Energy

- Silicon for Solar Photovoltaic Panels

Solar Storage Container Market Growth

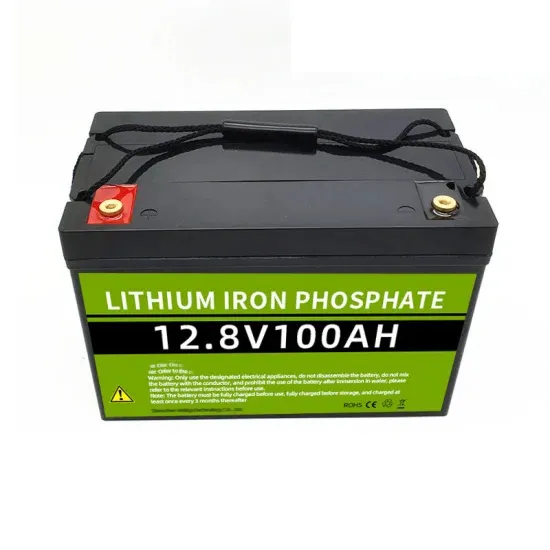

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

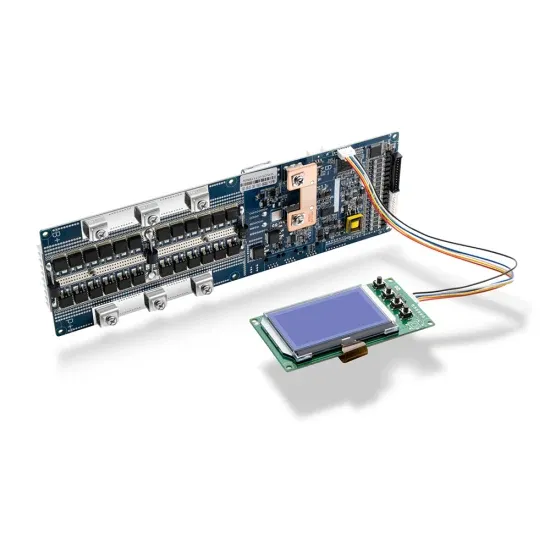

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.