Chart: Which country dominates the solar supply

Dec 23, 2022 · China has deployed a little more than one-third of the solar photovoltaic capacity in the world, but it controls a much larger share of the

How Are Solar Cells Made? A Complete Guide

Sep 2, 2023 · Introduction to Solar Cells Solar cells, also known as photovoltaic cells, are made from silicon, a semi-conductive material. Silicon is sliced into

Where Solar Panels Are Made: A Journey Through The

Dec 29, 2022 · Explore the world of solar energy production with this guide to the leading countries and companies that make solar panels. Learn where solar panels are made, how

10 Key Questions to Ask Solar Companies Before Installation

Jul 15, 2024 · Uncover the 10 crucial questions to ask before hiring a solar company in MA. Schedule a free consultation with Boston Solar, a trusted local installer.

Building Integrated Photovoltaics

Oct 12, 2021 · There are other solar cell technologies available in the market with potential use for building-integrated photovoltaic applications; however, they are still under development stages.

Health and Safety Impacts of Solar Photovoltaics

Oct 30, 2019 · Health and Safety Impacts of Solar Photovoltaics The increasing presence of utility-scale solar pho-tovoltaic (PV) systems (sometimes referred to as solar farms) is a rather

ENEL ANNOUNCES INTENTIONS TO BUILDSOLAR PV

Nov 17, 2022 · Construction of the proposed factory is expected to begin in the first half of 2023, and it''s anticipated that the first panel will be produced and available to the market by the end

The ''Future Made in Australia'' plan for solar panels relies on

Apr 23, 2024 · Twenty years ago China built a solar manufacturing industry on the back of Australian innovation. Now, as Australia tries to build a solar industry of its own, it needs

Professional Solar Installation

Solar panels installation is a process that involves setting up photovoltaic systems to capture sunlight and convert it into electrical energy. This installation typically requires a detailed

What are photovoltaic cells?: types and applications

Dec 17, 2024 · Photovoltaic cells, integrated into solar panels, allow electricity to be generated by harnessing the sunlight. These panels are installed on roofs, building surfaces, and land,

Solar energy and the environment

The U.S. Department of Energy is supporting various efforts to address end-of-life issues related to solar energy technologies, including recovering and recycling materials used to manufacture

6 FAQs about [Which factory does Boston solar photovoltaic panels come from ]

Where are solar panels made?

Determining where solar panels are made is not as easy as one might think. Of the world's top 10 solar panel manufacturers, seven are based in China, while only First Solar is based in the United States. The two remaining manufacturers on the list are from South Korea and Canada, though the latter is often considered Chinese as well.

Where are aluminum PV panels made?

Overall, a vast majority of aluminum PV manufacturers are from China. Out of a sample of 80 major frame producers, 59 are based out of China and the rest are scattered across 12 other countries. In a solar panel, the glass, encapsulant and backsheet are important for protecting the silicone cells from weather and exposure.

Which solar panels are made in the US?

Solar panels assembled in the the US have parts from China, India, and other countries all around the world – and vice versa. We don’t currently recommend any “American Assembled” solar panels. Our current panels are made by REC, LG, and Hanwha Q CELLS for residential systems. We use Astronergy for commercial installations.

What percentage of solar panels are made in the United States?

In 2022, the United States manufactured 1.9% of all solar panels. What Percentage Of Solar Panels Are Made In The U.S.? Despite manufacturing 1.9% of worldwide solar panels in 2022, the United States has seen significant growth. Public policy and consumer demand have prompted new manufacturing across the nation.

What is solar manufacturing?

Let’s explore. Solar manufacturing refers to the fabrication and assembly of materials across the solar supply chain. This includes not only solar photovoltaic (PV) panels, but items including batteries, inverters and racking equipment as well, each with its own unique chemical and physical makeup.

Where do solar PV modules come from?

By contrast, U.S.-based manufacturers produced 4.4 GW of solar PV modules. Imported modules came primarily from Asia, especially Malaysia, Vietnam, Thailand, and South Korea. China, whose imports are the subject of much political controversy, accounted for merely 1% of module imports to the U.S. at the end of 2020.

Update Information

- Photovoltaic solar panels at Mogadishu factory

- Photovoltaic panels solar energy supply factory

- Can we install solar photovoltaic panels

- Photovoltaic panels solar energy prices in Zambia

- Distributed photovoltaic solar panels in Finland

- Moscow installs solar photovoltaic panels

- Valletta rooftop solar photovoltaic panels

- Installation of solar panels and photovoltaic panels in the wild

- Rural rooftop solar panels photovoltaic panels

- Photovoltaic panels wholesale factory direct sales purchase

- Suspended solar photovoltaic panels

- Manufacturers sell brand new photovoltaic solar panels

- The effect of photovoltaic solar panels on Bulgarian roofs

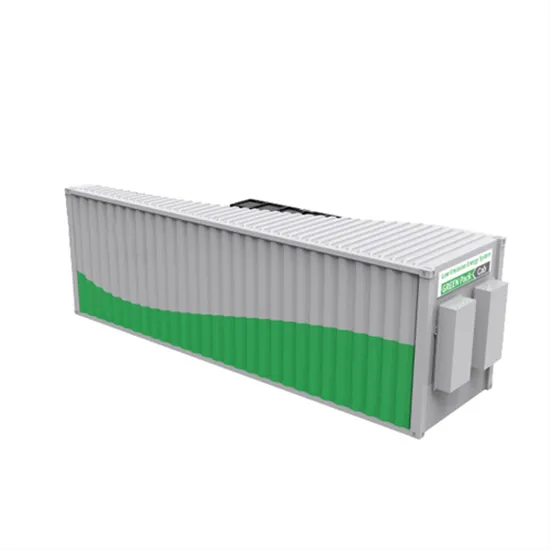

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.