Carbon emission assessment of lithium iron phosphate batteries

Nov 1, 2024 · The demand for lithium-ion batteries has been rapidly increasing with the development of new energy vehicles. The cascaded utilization of lithium iron

10 Best Energy-Efficient Home Batteries of 2025: Power Up

3 days ago · Weighing just 22.2 lbs, this lithium iron phosphate battery delivers 1280Wh of energy, doubling your driving range compared to lead-acid options. Its Bluetooth 5.0

Navigating Battery Choices: A Comparative Study of Lithium Iron

PDF | On Oct 1, 2024, Solomon Evro and others published Navigating Battery Choices: A Comparative Study of Lithium Iron Phosphate and Nickel Manganese Cobalt Battery

Environmental impact analysis of lithium iron phosphate batteries

Feb 28, 2024 · This paper presents a comprehensive environmental impact analysis of a lithium iron phosphate (LFP) battery system for the storage and delivery of 1 kW-hour of electricity.

What are the advantages of lithium iron phosphate battery?

May 10, 2025 · What Are the Advantages of Lithium Iron Phosphate Batteries? The Future of Energy Storage Lithium iron phosphate (LiFePO4 or LFP) batteries have emerged as the

Lithium-iron Phosphate (LFP) Batteries: A to Z

Mar 28, 2023 · These batteries have gained popularity in various applications, including electric vehicles, energy storage systems, and consumer electronics.

Lithium Iron Phosphate (LFP) Battery Energy Storage: Deep

Jun 26, 2025 · The Rise of LFP Battery Energy Storage Amid global carbon neutrality goals, energy storage has become pivotal for the renewable energy transition. Lithium Iron

Comparative Lifecycle Analysis: Lithium Iron Phosphate and Lead

Aug 8, 2025 · The comparison between Lithium Iron Phosphate (LiFePO4) and Lead-Acid batteries represents a significant milestone in this evolution, showcasing the shift towards

Life cycle assessment of lithium nickel cobalt manganese

Aug 1, 2022 · China has already formed a power battery system based on lithium nickel cobalt manganese oxide (NCM) batteries and lithium iron phosphate (LFP) batteries, and the

Lithium Iron Phosphate (LFP) Battery Energy Storage: Deep

Jun 26, 2025 · Amid global carbon neutrality goals, energy storage has become pivotal for the renewable energy transition. Lithium Iron Phosphate (LiFePO₄, LFP) batteries, with their triple

Lithium Iron Phosphate Battery vs. Lead-Acid Battery: Which

Feb 19, 2025 · In conclusion, lithium iron phosphate batteries are the superior choice for energy storage systems due to their longer lifespan, higher efficiency, and enhanced safety. For

The Future of Sustainable Living: Starmax LiFePO4 48V Battery

1 day ago · As the world shifts towards cleaner and more sustainable energy solutions, home energy storage systems have become increasingly popular. Among the leading innovations in

A comparative life cycle assessment of lithium-ion and lead

Jul 15, 2022 · This research contributes to evaluating a comparative cradle-to-grave life cycle assessment of lithium-ion batteries (LIB) and lead-acid battery systems for grid energy storage

Comparative Lifecycle Analysis: Lithium Iron Phosphate and Lead

Aug 8, 2025 · The evolution of battery technology has been a critical factor in the advancement of portable electronics, electric vehicles, and renewable energy storage systems. The

Lead-Acid vs. Lithium Iron Phosphate (LFP)

May 7, 2025 · As of 2023, LFP captures 38% of the stationary storage market that lead-acid once ruled, while costing just 2.1x more per kWh upfront but lasting

Decoding Battery Technologies: AGM, Lead-Carbon, and LiFePO4 Batteries

Sep 13, 2023 · Lithium Iron Phosphate (LiFePO4) batteries have taken the energy storage market by storm, offering high energy density, exceptional cycle life, and lightweight construction.

2025lithium iron phosphate energy storage cost

The lithium iron phosphate battery (LiFePO 4 battery) or LFP battery (lithium ferrophosphate) is a type of lithium-ion battery using lithium iron phosphate (LiFePO 4) as the cathode material,

Strategies toward the development of high-energy-density lithium batteries

May 30, 2024 · Strategies such as improving the active material of the cathode, improving the specific capacity of the cathode/anode material, developing lithium metal anode/anode-free

Environmental impact analysis of lithium iron phosphate

Jun 16, 2025 · 1 Introduction Moving toward carbon neutrality has become a consensus among major countries in the world. In recent years, the development of energy storage technology

Life cycle assessment of electric vehicles'' lithium-ion batteries

Nov 1, 2023 · Koh et al. [26] evaluated the energy storage systems of lithium titanate (LTO) batteries, lithium iron phosphate batteries, lead-acid batteries, and sodium-ion batteries with

A comparative life cycle assessment of lithium-ion and lead

Jul 15, 2022 · The lithium-ion batteries have fewer environmental impacts than lead-acid batteries for the observed environmental impact categories. The study can be used as a reference to

Lithium Iron Phosphate Batteries: 3 Powerful Reasons to

May 7, 2025 · The Battery Revolution: Understanding Lithium Iron Phosphate Lithium iron phosphate batteries are rechargeable power sources that combine high safety, exceptional

An overview on the life cycle of lithium iron phosphate:

Apr 1, 2024 · Lithium Iron Phosphate (LiFePO4, LFP), as an outstanding energy storage material, plays a crucial role in human society. Its excellent safety, low cos

The Levelized Cost of Storage of Electrochemical Energy

Jun 2, 2022 · The results show that in the application of energy storage peak shaving, the LCOS of lead-carbon (12 MW power and 24 MWh capacity) is 0.84 CNY/kWh, that of lithium iron

6 FAQs about [Energy storage lithium iron phosphate and lead carbon battery]

Are lithium phosphate batteries better than lead-acid batteries?

Finally, for the minerals and metals resource use category, the lithium iron phosphate battery (LFP) is the best performer, 94% less than lead-acid. So, in general, the LIB are determined to be superior to the lead-acid batteries in terms of the chosen cradle-to-grave environmental impact categories.

Why do lithium ion batteries outperform lead-acid batteries?

The LIB outperform the lead-acid batteries. Specifically, the NCA battery chemistry has the lowest climate change potential. The main reasons for this are that the LIB has a higher energy density and a longer lifetime, which means that fewer battery cells are required for the same energy demand as lead-acid batteries. Fig. 4.

What causes high ou of lithium iron phosphate batteries?

The positive and negative electrode materials of the batteries, the material side reactions of the electrolyte, the internal short circuit of the battery cores, and so on cause a high Ou of lithium iron phosphate batteries, as well as a power loss.

Which battery chemistries are best for lithium-ion and lead-acid batteries?

Life cycle assessment of lithium-ion and lead-acid batteries is performed. Three lithium-ion battery chemistries (NCA, NMC, and LFP) are analysed. NCA battery performs better for climate change and resource utilisation. NMC battery is good in terms of acidification potential and particular matter.

Do lithium-ion batteries have less environmental impact than lead-acid batteries?

The sensitivity analysis shows that the use-phase environmental impact decreases with an increase in renewable energy contribution in the use phase. The lithium-ion batteries have fewer environmental impacts than lead-acid batteries for the observed environmental impact categories.

What is the LCoS of lead-carbon and lithium iron phosphate?

Specific parameters for the three different types of EES projects. In Figure 8, the results show that the LCOS of lead-carbon is 0.84 CNY/kWh, that of lithium iron phosphate is 0.94 CNY/kWh, and that of vanadium redox flow is 1.21 CNY/kWh.

Update Information

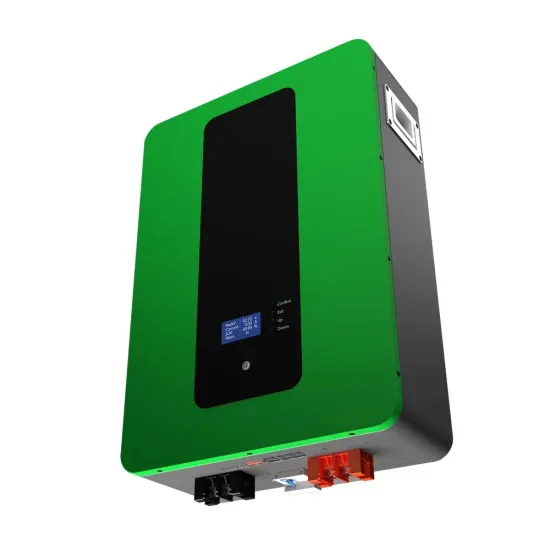

- Lithium iron phosphate single 12v energy storage battery

- Photovoltaic energy storage lithium battery lithium iron phosphate

- Energy storage lithium iron phosphate battery 48v

- Skopje energy storage battery lithium iron phosphate

- Three-phase energy storage lithium iron phosphate battery

- Czech Brno lithium iron phosphate energy storage battery

- Energy storage lithium iron phosphate secondary battery

- Advantages and disadvantages of lithium iron phosphate energy storage battery cabinet

- Backup energy storage lithium iron phosphate battery pack

- Vientiane lithium iron phosphate energy storage battery cabinet

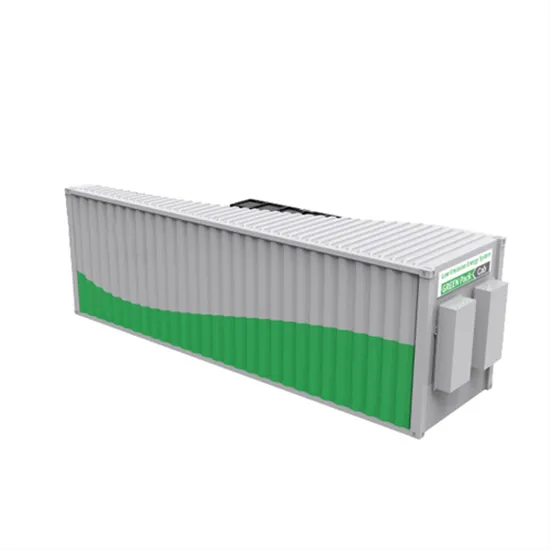

- Installation of lithium iron battery energy storage container

- Luxembourg lead carbon energy storage battery manufacturer

- Vaduz lithium iron phosphate energy storage system

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.