World''s 1st 8 MWh grid-scale battery with 541

Sep 9, 2024 · World''s first 8 MWh grid-scale battery in 20-foot container unveiled by Envision The new system features 700 Ah lithium iron phosphate batteries

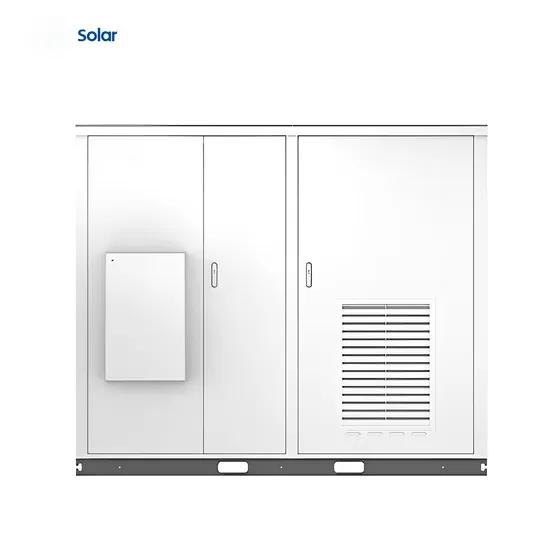

500kW Battery Energy Storage System

4 days ago · MEGATRONS 500kW Battery Energy Storage Solution is the ideal fit for commercial applications. Utilizing Tier 1 LFP battery cells, each commercial BESS is designed for a install

HIGH VOLTAGE CONTAINERIZED LITHIUM PHOSPHATE

Nov 22, 2021 · High voltage containerized lithium battery storage system is composed of high quality lithium iron phosphate core (series-parallel connection), advanced BMS management

Battery Energy Storage System (BESS) Factsheet

Nov 26, 2024 · Lithium-ion batteries Grid-scale lithium-ion batteries are made up of lithium iron phosphate or other lithium-based chemistries, capable of storing large amounts of energy in

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Battery storage systems are emerging as one of the potential solutions to increase power system flexibility in the presence of variable energy resources, such as solar and wind,

Detailed Understanding of the Containerized Battery System

Dec 13, 2024 · The containerized battery system has become a key component of contemporary energy storage solutions as the need for renewable energy sources increases. This system is

What are the installation requirements for energy storage containers

In this blog, I will delve into the installation requirements for energy storage containers, covering aspects such as site selection, electrical connections, safety measures, and environmental

Energy Storage Battery Container Installation: The Future of Power

Take California''s Moss Landing Energy Storage Facility – basically the Avengers HQ of battery containers. Their 1,200+ MW setup can power 1.2 million homes for four hours.

500kW/1000kWh Lithium Battery For C&I Energy

Apr 8, 2023 · The main principle of industrial ESS is to make use of lithium iron phosphate battery as energy storage,automatically charges and discharges

Development of Containerized Energy Storage System

Dec 24, 2014 · Our company has been developing a containerized energy storage system by installing a varyingly utilizable energy storage system in a container from 2010. The module

Installation process of energy storage container

Installation process of energy storage container A battery energy storage system (BESS) captures energy from renewable and non-renewable sources and stores it in rechar. eable batteries

2.5MW/5MWh Liquid-cooling Energy Storage System

Oct 29, 2024 · The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron

6 FAQs about [Installation of lithium iron battery energy storage container]

How are energy storage batteries integrated in a non-walk-in container?

The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron phosphate battery system, BMS system, power distribution system, firefighting system, DC bus system, thermal management system, and lighting system, among others.

Do battery energy storage systems look like containers?

C. Container transportation Even though Battery Energy Storage Systems look like containers, they might not be shipped as is, as the logistics company procedures are constraining and heavily standardized. BESS from selection to commissioning: best practices38 Firstly, ensure that your Battery Energy Storage System dimensionsare standard.

How are battery energy storage systems transported?

Given the Battery Energy Storage System’s dimen- sions, BESS are usually transported by sea to their destination country (if trucking is not an option), and then by truck to their destination site. A.Logistics The consequence is that the shipment process can be worrisome.

Can a battery storage system increase power system flexibility?

sive jurisdiction.—2. Utility-scale BESS system description— Figure 2.Main circuit of a BESSBattery storage systems are emerging as one of the potential solutions to increase power system flexibility in the presence of variable energy resources, suc

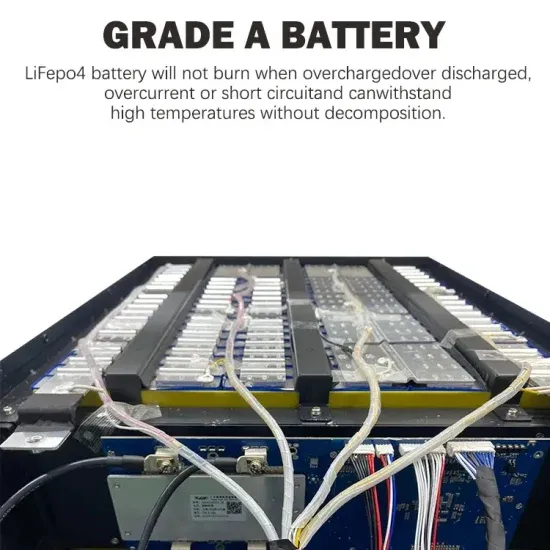

What chemistry is used in battery energy storage system?

Do a quick research. •Battery cell chemistry:LFP (Lithium iron phos- phate – chemical formula LiFePO4) is the main chemistry used in the Battery Energy Storage System industry due to lower cost and increased safety.

When should a battery energy storage system be inspected?

Sinovoltaics advice: we suggest having the logistics company come inspect your Battery Energy Storage System at the end of manufacturing, in order for them to get accustomed to the BESS design and anticipate potential roadblocks that could delay the shipping procedure of the Energy Storage System.

Update Information

- Harare Energy Storage Lithium Iron Phosphate Battery Company

- Price of container energy storage lithium battery

- Bloemfontein lithium battery energy storage container manufacturer

- How about lithium iron phosphate battery for photovoltaic energy storage cabinet

- Danish lithium iron phosphate energy storage battery cabinet

- Ghana lithium iron phosphate energy storage battery

- Tirana lithium battery energy storage cabinet installation factory operation

- Energy storage lithium iron phosphate and lead carbon battery

- Photovoltaic energy storage lithium battery lithium iron phosphate

- Cape Town lithium battery energy storage cabinet installation factory is running

- Belize Energy Storage Lithium Battery Installation Company

- Spanish container energy storage lithium battery

- The latest lithium battery energy storage container solution

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.