Designing a BESS Container: A Comprehensive Guide to Battery Energy

Apr 10, 2023 · The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

What is energy storage box production | NenPower

Jul 18, 2024 · The production is driven by increasing demand for renewable energy solutions, leading to innovations in battery technology, 3. It encompasses various types of energy

DuPont Solutions for Stationary Battery Energy Storage

Aug 21, 2024 · DuPont has a wide portfolio of battery pack assembly and thermal management solutions that have been validated and specified with EV and lithium-ion battery manufacturers

DuPont Solutions for Stationary Battery Energy Storage

Aug 21, 2024 · DuPont Solutions for Stationary Battery Energy Storage Systems Power transmission and distribution needs are changing rapidly as power grids age, assets are

Energy storage box automatic assembly system

Dec 11, 2020 · What is an energy storage system? An energy storage system is a packaged solution that stores energy for use at a later time. The system''s two main components are the

Presentación de PowerPoint

Sep 30, 2021 · Energy Capacity Guarantee: • The Energy Capacity Guarantee gives maximum acceptable reduction in system energy capacity as a function of time and as a function of

The Key Components of Battery Energy Storage Systems (BESS)

Aug 18, 2025 · Understand battery energy storage system components and how their design impacts the efficiency and reliability of BESS including diagrams.

Battery energy storage system modeling: A combined

Feb 1, 2019 · Battery pack modeling is essential to improve the understanding of large battery energy storage systems, whether for transportation or grid storage. I

Battery System Development – Assembly Planning between Lightweight

Jan 1, 2014 · Battery systems of electric vehicles suffer from low energy densities as well as high masses and geometrical complexity. The absence of standards for battery cells and peripheral

Assembly line for battery modules and battery packs

6 days ago · For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These

Prefabricated Energy Storage System Solution

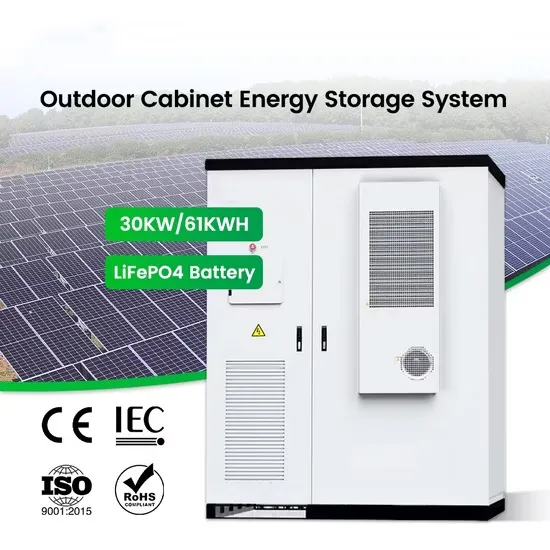

Prefabricated energy storage systems are a commonly utilized configuration for large-scale energy storage projects, integrating features such as lithium iron phosphate battery packs for

6 FAQs about [Box-type energy storage system assembly plant]

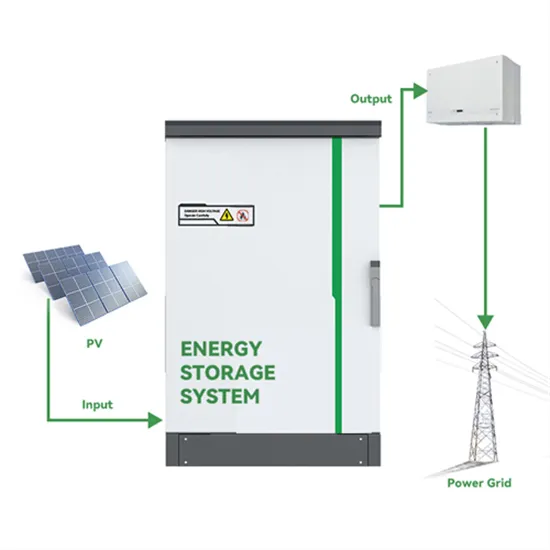

What is a containerized battery energy storage system?

Containerized Battery Energy Storage Systems (BESS) are essentially large batteries housed within storage containers. These systems are designed to store energy from renewable sources or the grid and release it when required. This setup offers a modular and scalable solution to energy storage.

What is a stationary battery energy storage system?

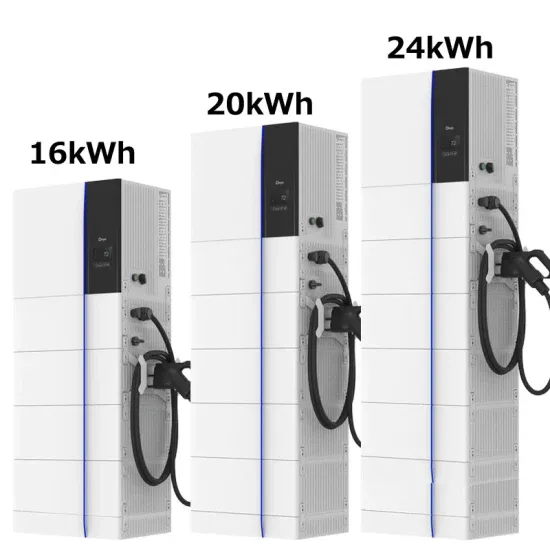

Stationary battery energy storage systems (BESS) are showing a lot of promise, and as technology grows within the electric vehicle market, application development specialists are rapidly adapting that technology as a storage solution. Stacked battery packs of various sizes and configurations are connected to form large assemblies.

What is a battery energy storage system (BESS)?

The amount of renewable energy capacity added to energy systems around the world grew by 50% in 2023, reaching almost 510 gigawatts. In this rapidly evolving landscape, Battery Energy Storage Systems (BESS) have emerged as a pivotal technology, offering a reliable solution for storing energy and ensuring its availability when needed.

Are energy storage containers a viable alternative to traditional energy solutions?

These energy storage containers often lower capital costs and operational expenses, making them a viable economic alternative to traditional energy solutions. The modular nature of containerized systems often results in lower installation and maintenance costs compared to traditional setups.

What is Jabil energy storage system?

Jabil engineers, builds and ramps some of the most innovative and complex Energy Storage System (ESS) products in the world. ESS solution providers benefit from Jabil’s unique combination of high-level assembly (HLA), power engineering and global manufacturing capabilities.

What segments does offer?

It includes segments: Vehicle - OEM, Parts. has the right instrumentation, analyzers, force measurement solutions and digital solutions for every stage of the battery manufacturing process - from upstream to downstream to storage.

Update Information

- Norway energy storage lithium battery assembly plant

- Moldova box-type energy storage power station

- Automated assembly of energy storage batteries

- Abu Dhabi energy storage equipment production and assembly

- New Zealand high voltage energy storage lithium battery assembly

- Cameroon Douala Power Plant Energy Storage Project

- Dakar Phase Change Energy Storage System Production Plant

- How big of an energy storage system should a photovoltaic plant use

- Energy storage photovoltaic assembly

- Huawei Malta lithium battery energy storage plant

- Design of power plant with energy storage station

- Reykjavik Energy Storage Plant Cost

- Dhaka photovoltaic plant energy storage project construction

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.