Norway energy storage lithium

Is stationary energy storage a good idea in Norway? ''s first electric fast ferry. In a global report on lithium-ion batteries, Norway r nked first in sustainability. These are impressive records. Even

Morrow inaugurates 1-GWh LFP battery factory

Aug 23, 2024 · Industrial battery technology company Morrow Batteries ASA has formally inaugurated its new factory for Lithium Iron Phosphate (LFP) batteries

Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

Innovating battery assembly

Aug 13, 2025 · EV batteries have become an integral part of the vehicle structure, making lithium-ion cell assembly and their integrity a safety-critical issue. One major diferentiating feature of

Norway''s Morrow Batteries opens factory, plans

Aug 16, 2024 · Founded in 2020, Morrow Batteries will initially use existing lithium iron phosphate (LFP) technology and its plant in Arendal, southern Norway, is

On industrial pasts and futures: Imagining a large-scale battery

Jun 1, 2025 · The company had just revealed plans to build a large-scale lithium-ion battery cell manufacturing plant in southern Norway – known in the industry as a ''Gigafactory''. 1 Cells

Norway''s maturing battery industry embraces green energy storage

May 8, 2023 · Electric cars now account for 79 per cent of new cars sold in Norway, and the MS Medstraum was recently launched as the world''s first electric fast ferry. In a global report on

Automated assembly of Li-ion vehicle batteries: A feasibility study

Jan 1, 2020 · Electric Vehicles (EVs) with rechargeable Lithium-Ion batteries (Li-ion) are at the forefront of the global trend for lower-emission transportation and decarbonisation. Capable

Renewable-powered lithium-ion battery recycling plant in Norway

Feb 1, 2021 · A lithium-ion battery recycling plant is under construction in Norway, focusing initially on electric vehicle (EV) batteries, but the CEO of the company behind it has said that it will

Morrow Inaugurates Europeʼs First LFP Gigafactory

Aug 19, 2024 · Norwegian start-up Morrow Batteries has opened Europeʼs first gigafactory for lithium iron phosphate (LFP) batteries in Arendal, Norway. The facility will be capable of

''Horrifying'' fire at California lithium battery plant

Jan 26, 2025 · When a massive fire erupted at one of the world''s largest lithium-ion battery storage facilities in Monterey County, it didn''t just send a toxic

A Norwegian battery company is building a

Feb 17, 2024 · Freyr Battery is developing a manufacturing process for lithium-ion batteries. The CEO talks about the massive effect of the Inflation Reduction Act.

Oslo Energy Storage System: How Lithium Batteries Power

Oct 20, 2024 · But here''s the kicker: Norway''s capital is quietly becoming a global poster child for energy storage innovation. With its ambitious climate goals and tech-savvy population, Oslo''s

6 FAQs about [Norway energy storage lithium battery assembly plant]

Are batteries a potential green industry in Norway?

McKinsey & Co. has identified batteries as one of Norway's principal potential green industries in the future. According to the consultancy, a rapid and broad strengthening of all parts of the battery value chain is needed to satisfy the global battery shortage.

What is Nordic batteries doing with Morrow batteries & eldrift?

Nordic Batteries announces it is entering into a strategic partnership with Morrow Batteries and Eldrift to develop complete battery packs for mobile and stationary battery energy storage solutions (BESS). The overall project and product pipeline amounts to 7 GWh until 2030.

Where does Nordic batteries build a fully automated battery assembly plant?

With its Industry 4.0 initiative, Nordic Batteries builds a fully automated agile battery assembly plant. The pilot plant is developed in the BATNET-project and will be operational Q1 24. The company has locations in Kongsberg and Høvik outside Oslo.

What is the new battery industry in Norway?

The new industry in Norway related to batteries promises economic growth, up to 30’000 jobs, regional development, and technological innovation. In its latest climate action plan, the government identified industries along the battery supply chain as key to ‘green growth'.

Can Norway construct a battery cell Gigafactory?

Several companies are planning to build battery cell Gigafactories in Norway. Although the emerging industry is promising new ‘green’ economic growth for the oil-dependent country, it is reliant on lithium and other raw materials that are extracted elsewhere.

How many GWh will Nordic batteries deliver in 7 years?

The company has secured a delivery agreement for 5.5 gigawatt hours (GWh) over seven years with Nordic Batteries, which builds customised storage solutions. The first months will be spent tweaking the process, improving quality and get to a stable production of battery cells, he added.

Update Information

- Power plant lithium battery energy storage power station price

- Norway lithium battery energy storage project

- Huawei Malta lithium battery energy storage plant

- New Zealand high voltage energy storage lithium battery assembly

- Nicaragua Energy Storage Lithium Battery Export Company

- Czech lithium battery energy storage company

- Energy storage lithium battery major

- Roman energy storage lithium battery manufacturer

- Albania lithium battery energy storage cabinet price base station

- Use of lithium battery for energy storage

- Advantages and disadvantages of lithium iron phosphate energy storage battery cabinet

- Bucharest photovoltaic power plant energy storage battery

- Box-type energy storage system assembly plant

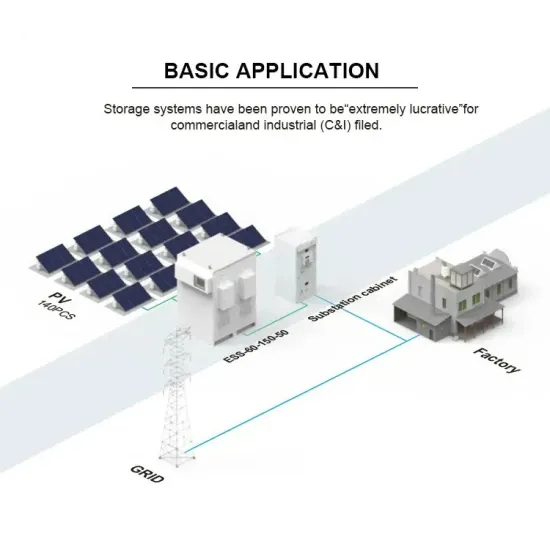

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.