Development of Wind Turbine Blade Pitch Controller

May 6, 2025 · When the wind speed and direction change, hydraulic pitch control devices are utilized to modify the angle of the turbine blades. The technology can adjust the pitch angle to

Wind power variable pitch battery assembly

The control unit is powered by an in-built power supply and a 12 V rechargeable battery. The 12 V rechargeable battery powers the control unit at ''''switch-on'''' and when the input mains voltage

What are the wind turbine variable pitch energy storage batteries

what size battery do you need for wind turbine storage When it comes to storing energy from a wind turbine, the size of the battery you need will depend on a variety of factors. In this article,

What are the functions of the variable pitch battery pack

Suitable for battery packs with multiple cells; it balances the cells'''' SOC during charging, enhances the batteries'''' health, and trades off between competing factors as it maximizes

What are the benefits of Variable Pitch Propellers?

Dec 19, 2019 · Variable pitch propellers are a special type of propeller that allows for the change of the blade angle during flight, opening up new abilities to increase performance. In this blog,

What are the wind turbine variable pitch energy storage batteries

The variable speed pitch regulated wind turbine often operates at the maximum wind energy capture mode. At that mode, the wind power varies with the wind speed.

Six-cabinet control system for variable-pitch wind-driven

The invention discloses a six-cabinet control system for variable-pitch wind-driven power generation, which comprises three shaft control cabinets. The three shaft control cabinets are

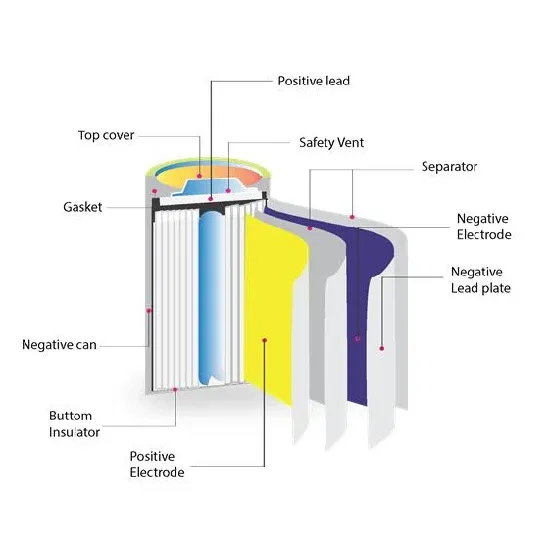

Understanding the Lithium

Mar 17, 2025 · Working Principle The basic working principle of a lithium - battery aging cabinet is centered around mimicking real - world usage scenarios for the batteries. When a new lithium

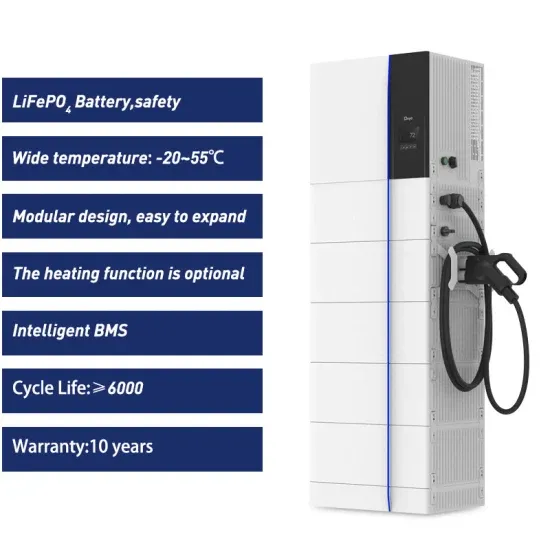

Working principle of battery cabinet in energy storage

For a battery energy storage system to be intelligently designed, both power in megawatt (MW) or kilowatt (kW) and energy in megawatt-hour (MWh) or kilowatt-hour (kWh) ratings need to be

Wind power variable pitch battery

Control of Variable Pitch and Variable Speed Direct-Drive Wind In this paper the sustainability of a 2 KW hybrid of wind and battery arrangement is examined for meeting the necessities of a

Variable Frequency Energy Storage: The Future of Flexible

Why Variable Frequency Energy Storage Matters Now Ever wondered how your smartphone charges so efficiently during a stormy blackout? Enter variable frequency energy storage

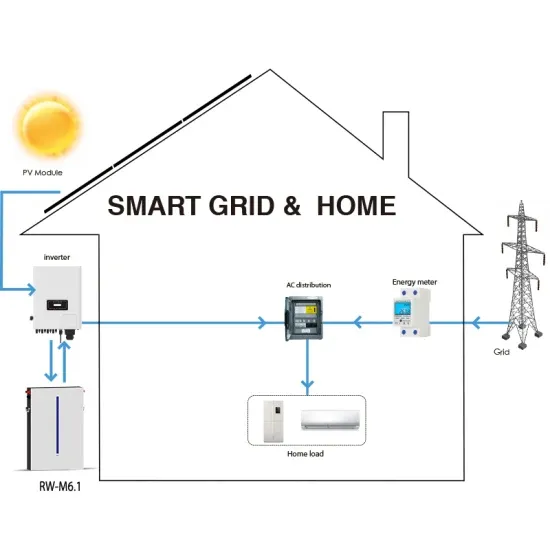

Working principle of photovoltaic energy storage battery cabinet

The Working Principle Behind Solar Battery Technology How do solar batteries work? Solar batteries store energy from the sun, allowing us to use solar power anytime. In this article,

Hydraulic variable pitch technology of wind power

Feb 23, 2025 · Hydraulic and electric variable-pitch technologies, as two common variable-pitch technologies, have their unique advantages and limitations in wind power generation and

Variable-pitch battery module automatic assembly system

A battery module and automatic assembly technology, applied in battery assembly, secondary battery manufacturing, transportation and packaging, etc., can solve the problems of deviation,

Working principle of battery cabinet in energy storage

A battery energy storage system (BESS) or battery storage power station is a type of energy storage technology that uses a group of batteries to store electrical energy.

WORKING PRINCIPLE OF PHOTOVOLTAIC ENERGY STORAGE BATTERY CABINET

Working Principle of Lithium Battery Energy Storage Power Station A battery energy storage system (BESS) or battery storage power station is a type of energy storage technology that

Working principle of battery cabinet in energy storage

Battery energy storage systems are generally designed to be able to output at their full rated power for several hours. Battery storage can be used for short-term peak power and ancillary

Technical requirements for variable pitch batteries

A Comprehensive Model of Variable Pitch Electric Propulsion Unit In response to high-efficiency and high-performance thrust control requirements of variable pitch electric

5 FAQs about [What is the principle of the variable pitch battery cabinet]

What is a battery pitch control system?

Battery pitch control systems, also known as Battery Energy Storage Systems (BESS) pitch control, refer to the use of battery technology for the purpose of pitch control in wind turbines.

What are the benefits of battery pitch control systems in wind turbines?

Pitch control systems in wind turbines have traditionally used grid-powered hydraulic or electric technologies. However, battery pitch control systems provide a number of benefits, such as improved dependability, increased energy economy, and the capacity to operate off the grid.

What is pitch control in wind turbines?

Pitch control is an essential feature in wind turbines that allows the rotor blades to maintain a consistent speed and optimize power generation based on wind conditions. Pitch control systems in wind turbines have traditionally used grid-powered hydraulic or electric technologies.

What is a hydraulic pitch control device?

When the wind speed and direction change, hydraulic pitch control devices are utilized to modify the angle of the turbine blades. The technology can adjust the pitch angle to optimize the quantity of wind energy captured and control the turbine’s rotating speed.

What is the difference between stall control & pitch control?

The distinction between the controlling pitch & stall of WT is most visible at higher wind speeds. The stall-controlled system relies on the aerodynamic design of blades to control aerodynamic torque or rotational speed of turbine at high wind speeds. The blades are controlled by active pitch control in pitch-controlled systems.

Update Information

- Variable pitch battery cabinet model

- What is the most suitable size for a new energy battery cabinet

- What does esc represent at the battery cabinet site

- What are the battery cabinet communication power supply technologies

- What are the new energy battery cabinet cloth manufacturers

- What is the minimum current required for the range extender battery cabinet

- What is the appropriate price for energy storage battery cabinet

- What does the lithium battery station cabinet system consist of

- What are the components of the emergency battery cabinet

- What should the battery cabinet current be

- What are the battery cabinet charging technologies

- What is the function of wind farm battery cabinet

- What is the brand of new energy battery cabinet

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.