V5 user manual-PYTES 1.3

Mar 25, 2024 · Our V series battery pack is designed to provide safe, high-performance energy storage solutions for a variety of applications. The compact and easy-to-install battery pack

DESIGN FOR SAFE AND RELIABLE ELECTRICAL

Jan 23, 2019 · DESIGN FOR SAFE AND RELIABLE ELECTRICAL PROTECTION OF BATTERY SYSTEM These guidelines are specifically designed for electrical systems in EMEA, Asia and

Eaton s lithium-ion UPS battery Q&A

Mar 21, 2025 · This document will serve as a guide for Eaton salespersons, sales support personnel, engineering clients, and end users who have questions regarding the lithium

Battery Cabinet Working Space Front Aisle Floor Loading

Placing a DC system with an indoor cabinet allows installation in areas other than a dedicated electrical or battery rooms allowing more flexiblity on the installation location while still meeting

Accuracy requirements for battery aging cabinets in battery

Jun 30, 2025 · The accuracy of the aging cabinet is a key indicator in the production process of battery PACK, which directly affects the accuracy and reliability of battery performance testing.

-48 VDC Battery Cabinet Installation and User Manual

Apr 21, 2022 · Although the DC voltage is not hazardously high, the battery can deliver large amounts of current. Exercise extreme caution not to inadvertently contact or have any tool

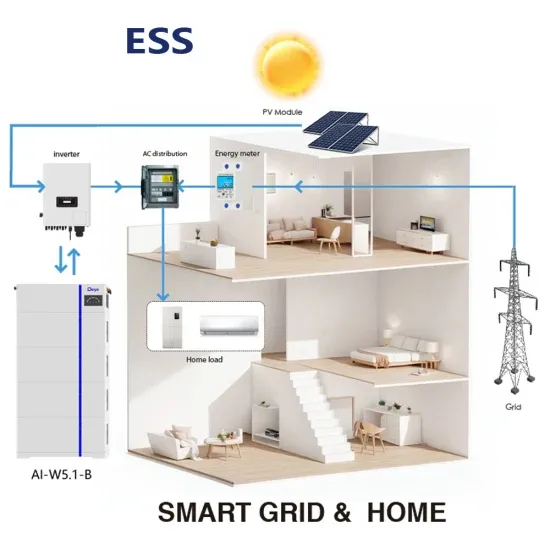

How does a cabinet battery work?

Jun 30, 2025 · As a seasoned cabinet battery supplier, I''ve witnessed the growing curiosity around how these essential power storage units operate. Cabinet batteries are pivotal in

How to calculate battery room hydrogen ventilation

How to calculate hydrogen ventilation requirements for battery rooms.For standby DC power systems or AC UPS systems, battery room ventilation is calculated in accordance to EN 50272

Battery cabinet installation in weak current room

Batteries exceeding charging power of 2 kW shall be installed in closed cabinets, containers or battery rooms forced ventilated to open deck area. Lead batteries up to 3 kW may be

BATTERY CABINETS VS. BATTERY RACKS

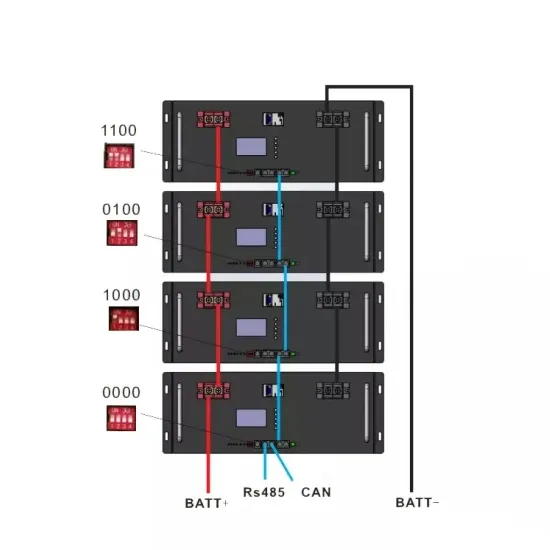

How to connect parallel battery cabinets The basic concept is that when connecting in parallel, you add the amp hour ratings of the batteries together, but the voltage remains the same. For

-48 VDC Battery Cabinet Installation and User Manual

Apr 21, 2022 · battery can present a risk of electrical shock and high short circuit current. Servicing of batteries should be performed or supervised only by properly trained and

Tips for Designing Battery Cabinets/Enclosures | SBS Battery

Jan 16, 2025 · Minimum cabinet height = Rack height (to top of rail) + Battery height + Space above battery (12" ideal) + Charger height + 6" (for space above charger) Chargers need room

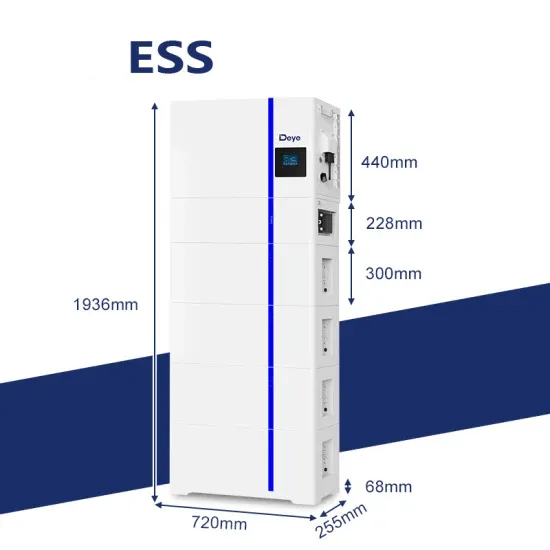

USER MANUAL BATTERY CABINET

Jul 28, 2025 · Cable sizing from the battery cabinet to the remainder of the ESS is dependent on multiple factors including the system maximum current draw, distance between the battery

Specifications and models of cabinets in weak current

A lithium ion battery cabinet is a specialized enclosure designed to house lithium-ion batteries. These cabinets are engineered to ensure the safe operation of battery

UBC87 Battery Cabinet Installation, Operation,

Jul 21, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

ESTEL Battery Storage Cabinets for Lithium-Ion

May 13, 2025 · Choose the best battery storage cabinet for lithium-ion batteries with fire-resistant materials, ventilation, and safety features to ensure optimal

Battery Cabinet Solutions: Ensuring Safe Storage and

Lithium-ion batteries are essential in powering tools, devices, and energy systems across industries, but they also come with inherent fire and explosion risks. To address these

版本说明书

Jan 9, 2025 · If the Battery Cabinet must be rewired, relocated, or maintained, all sources of external and internal power must be disconnected and electrically isolated. To avoid the risk of

Choosing the Right Lithium Ion Battery Cabinet: A Complete

May 1, 2025 · Ensure maximum safety and efficiency with this in-depth guide on selecting a lithium ion battery cabinet. Learn key features, regulations, and storage solutions to protect

PRACTICAL CONSIDERATIONS WHEN DESIGNING A BATTERY

Specifications and models of battery cabinets in weak current room This article looks at the preferred designs for battery rooms and discusses how batteries should be laid out to give a

Battery Cabinet Current Limits | We Group E-Site

Have you ever wondered why battery cabinet current limits account for 43% of thermal runaway incidents in grid-scale storage systems? As renewable integration accelerates globally, the

Eaton three-phase UPS battery handbook

Apr 3, 2025 · Full-float operation – Operation of a DC system with the battery, battery charger and load connected in parallel, with the battery charger supplying the normal DC load plus any self

6 Battery Energy Storage Systems — Lithium | UpCodes

[C] 4-8 There are no current commercially available lithium battery chemistries that provide a significantly different margin of fire safety over any other lithium battery chemistry. This

What battery model should I buy for capacitor cabinets

CellBlock Battery Storage Cabinets are a superior solution for the safe storage of lithium-ion batteries and devices containing them. Our practical, durable cabinets are manufactured from

Calculating Battery Current | Information by Electrical

Jun 21, 2014 · Seems odd for a cabinet with two 400A breakers. Your current will be controlled mostly by the load. Short circuit current of each string at the breaker is the battery charged

BC Series UPS Battery Cabinets

Jun 9, 2023 · Over-Current on Charge – Max current should not exceed 160Amps per string from the battery charger for more than 15 seconds. The BMS will open contactor for 135s and not

How to design an energy storage cabinet: integration and

Jan 3, 2025 · The following are several key design points: Modular design: The design of the energy storage cabinet should adopt a modular structure to facilitate expansion, maintenance

6 FAQs about [What should the battery cabinet current be ]

How many battery cabinets can be connected together?

The battery cabinet is designed to be daisy-chained together with additional battery cabinets. There is no limit to the number of battery cabinets that can be connected together. However, a maximum system current of 30 A should be maintained regardless of the number of interconnected battery cabinets. Procedure NOTE! Refer to Figure 7

How do I connect a battery cabinet to a power system?

Procedure 1. Furnished with the battery cabinet are battery disconnect circuit breaker alarm lead assemblies. Refer to the power system installation manual to use these alarm leads to connect the battery cabinet battery disconnect circuit breaker alarm into the power system alarm circuits.

What is a battery lead cable?

Battery Leads Cables with connectors are provided on the associated power system and the battery cabinet to allow simple interconnections between a battery cabinet and the associated power system and between battery cabinets. The battery cabinet is designed to be daisy-chained together with additional battery cabinets.

How do you put a 4th Battery in a cabinet?

Place another inner battery spacer next to the third battery. 9. Set fourth battery in cabinet (being careful of the door fastener tabs hanging down) and attach the other end of the fast-on lugged cable to the negative terminal on the third battery (fast-on terminal).

How do I install a VDC battery cabinet?

Set first battery in cabinet and attach the long lead (fast-on connector side marked positive) from the cabinet to the fast-on terminal on the positive terminal of the battery. See Figure 24. Facing left Facing right Facing left Vertiv™ NetSure™ 211 SERIES -48 VDC Battery Cabinet Installation & User Manual (Section 6023) Rev. L 23 Figure 24:

What precautions should be taken when working on batteries?

The following precautions should be observed when working on batteries: • Follow the recommended PPE requirements per the SDS for the battery to be used. • Batteries are an energy source that can produce high amounts of electrical current. • Remove watches, rings, and other metal objects.

Update Information

- What should the battery cabinet current be

- What is the current of the battery cabinet capacity

- How much current does a 9v battery in an energy storage cabinet have

- What are the components of the emergency battery cabinet

- Battery cabinet continuous current

- How much current does the energy storage cabinet battery output

- Energy storage cabinet 9v battery discharge current 200ma

- The function of weak current backup battery cabinet

- Maximum operating current of the energy storage cabinet battery

- What is the function of lithium battery cabinet

- What to pay attention to when inspecting a DC battery cabinet

- What are the Nordic outdoor communication battery cabinet suppliers

- What are the outdoor communication battery cabinet companies in the United Arab Emirates

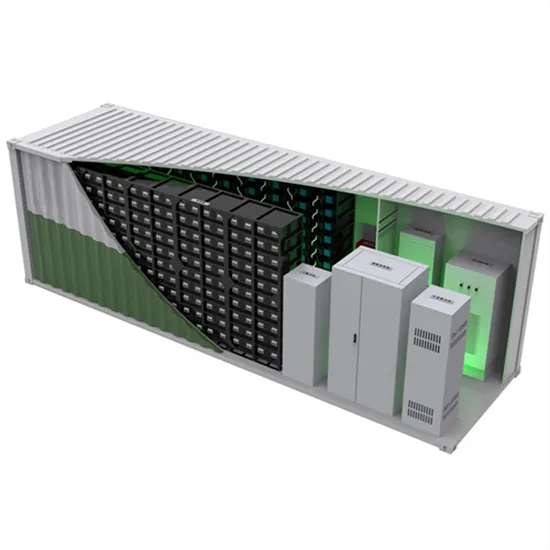

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.