Managing photovoltaic Waste: Sustainable solutions and

Nov 15, 2024 · The PV market is currently dominated by crystalline silicon (c-Si) PV panels, comprising approximately 97 % of total production in 2023 [2]. The majority of solar PV

Assessing the sustainability of solar photovoltaics: the case of glass

Sep 12, 2024 · The life cycles of glass–glass (GG) and standard (STD) solar photovoltaic (PV) panels, consisting of stages from the production of feedstock to solar PV panel utilization, are

Selective grinding of glass to remove resin for silicon-based

Mar 1, 2021 · Secondary grinding for glass recovery from silicon-based PV panels was investigated. Grinding at 2500 rpm for 5 min with an eccentric stirring mill was optimal. Glass

Unlocking silver from end-of-life photovoltaic panels: A

Mar 1, 2025 · In recent years, the photovoltaic (PV) industry has been dominated by mono or polycrystalline silicon panels, which represent the most sophisticated technology. Although

Can photovoltaic panels be removed from the frame and used

About Can photovoltaic panels be removed from the frame and used Waste from end-of-life solar panels presents opportunities to recover valuable materials and create jobs through recycling.

Development of PV panel recycling process enabling

Jul 1, 2025 · However, recycling end-of-life (EOL) photovoltaic (PV) modules or panels is extremely challenging due to the complex structure of the panels. Crystalline silicon (c-Si)

Recycling of end of life photovoltaic solar panels and

Feb 1, 2024 · With the current rate of installation of photovoltaic (PV) modules, the total installed capacity is expected to reach 4500 GW by 2050. Given the average life of solar modules is 25

An overview of solar photovoltaic panels'' end-of-life material

Jan 1, 2020 · End-of-life (EOL) solar panels may become a source of hazardous waste although there are enormous benefits globally from the growth in solar power gen

Photovoltaic panels have been removed from the glass

Can solar PV panels be recycled at end-of-life? In this work, some aspects of the thermal process for recovery of silicon, glass and metals from silicon PV panels were investigated. A

The use of recycled semiconductor material in crystalline silicon

Feb 1, 2020 · After the cells have been separated from PV modules, the various layers of material applied in the production process must be removed in a specific order: front metal coating,

A comprehensive review on the recycling technology of

Apr 5, 2024 · Recycling PV panels through e-waste management is crucial step in minimizing the environmental impact of end-of-life PV systems such as the release of heavy metals into the

Can the outer glass of photovoltaic panels be removed

Can radio-frequency heating remove broken glass from PV panels? Doni et al. applied the technology of radio-frequency heating to the delamination of PV modules and can easily

Solar photovoltaic recycling strategies

Mar 1, 2024 · This paper overviews the commitment level of different countries to solar PV recycling. It summarizes the various solar PV recycling strategies for different types of solar

Can I still use my solar PV panels with broken glass?

Green and widely sourced solar energy resources have become the new energy source of the 21st century. Solar street light is now the master of lighting in our life, and more and more

Investigation of combustion hazards of glass photovoltaic panels

May 15, 2025 · At present, the application scale of glass panel photovoltaic modules worldwide is rapidly increasing, and they are widely used in centralized and distributed photovoltaic power

PV panel re-use around the world: State-of-the-art

May 1, 2024 · Within the Australian context, discussions about reusing, repairing, and refurbishing PV panels have been prevalent in various industry reports [17]–[19]. These reports

Sustainable Solar: Recycling Photovoltaic Panels for a

Feb 5, 2025 · Index Terms-Circular economy, end-of-life PV panels, extended producer responsibility (EPR), photovoltaic recycling, renewable energy waste management, silicon

How to remove the glass from waste photovoltaic panels

The EU Waste of Electrical and Electronic Equipment (WEEE) Directive entails all producers supplying PV panels to the EU market to finance the costs of collecting and recycling EOL PV

Life Cycle Assessment of Recycling Waste Glass from Retired

Jul 29, 2025 · As the cumulative waste of retired photovoltaic (PV) modules is projected to exceed 1 million tons by 2030, the resultant loss of silicon, glass, and valuable metals has become a

Towards sustainability via recycling solar photovoltaic Panels

Jan 1, 2025 · Human activities are placing a progressively increasing demand on energy consumption. Renewable energy resources are a promising alternative to fossil fuels due to

Physical Separation and Beneficiation of End-of-Life Photovoltaic

May 11, 2020 · One of the technical challenges with the recovery of valuable materials from end-of-life (EOL) photovoltaic (PV) modules for recycling is the liberation and separation of the

Recycling of photovoltaic modules for recovery and

Apr 1, 2023 · Recycling of PV comprises repairing, direct reuse, and recycling of materials chemically and mechanically from different types of decommissioned photovoltaic modules.

The Use of Glass from Photovoltaic Panels at the End of

Nov 4, 2021 · This article deals with the use of photovoltaic panels at the end of their life cycle in cement composites. Attention is focused on the properties of cement composite after 100%

A review of self-cleaning coatings for solar photovoltaic

Jul 27, 2023 · TiO 2 is widely used to prepare super-hydrophilic coatings on glass covers of photovoltaic panels due to its good photocatalytic activity. CVD-based surface treatment is

Removal of encapsulant Ethylene-vinyl acetate (EVA) from

Jan 1, 2024 · Photovoltaic modules (PVMs) are a very promising way to meet future energy needs. As traditional energy sources aren''t sustainable, the only way to meet future energy

Life cycle assessment of decommissioned silicon photovoltaic

Nov 1, 2024 · For recovered glass and silicon, they are remanufactured into new solar glass and solar-grade silicon, respectively, for incorporation into the production of new photovoltaic

Advances in approaches and methods for self-cleaning of

Mar 1, 2018 · In this article, attempt has been made to review the progress and achievements in all kinds of self-cleaning methods for PV panels with special focus on super hydrophobic

Overview of global status and challenges for end-of-life

Jun 1, 2021 · Recent developments in photovoltaic (PV) technology have enabled a reduction of fossil fuel usage and subsequent carbon dioxide (CO 2) release from energy production.

6 FAQs about [Photovoltaic panels have been removed from the glass]

Why do we need to treat used PV panels?

Photovoltaic panels (solar cells) have been widely applied all over the world as renewable energy resources. Since the average lifetime of PV panel is about 20 years, considerable amount of waste PV panels are accumulating every year. Therefore, there are increasing demand for the environmentally friendly process to treat used PV panels.

How to remove resin from glass in silicon-based PV panel recycling?

As mentioned above, the most extensively studied methods for the removal of resin from glass in silicon-based PV panel recycling involve heating or chemical additives , , . However, we developed a mechanical separation technology to rapidly effect the separation with low environmental load and low energy consumption.

Can a PV panel be used as a raw material?

The selectivity was high at a high rotation speed and during the initial stage of grinding. We found that 97% of the glass in a PV panel can be recovered with less than 1% C contamination for particles smaller than 5.6 mm by grinding at 2500 rpm for 5 min. The resulting glass particles are suitable for use as raw material for glass fiber.

How long will a solar PV panel last in Southeast Asia?

The project will be the most significant floating PV source in southeast Asia, having more than 1 million PV modules assembled. The approximate lifetime of a PV panel is about 25-30 years. Therefore, these solar PV wastes will be enormous at the end of life and may cause a big problem.

Is microwave a good option for delaminating PV panels?

After heating the PV panel with a microwave, the results showed that removing the glass pane could be conveniently conducted easier than a non-heated panel by about 50-60% of the force. In summary, the microwave frequency appeared to be an attractive option for delaminating expired or damaged PV panels.

How long do solar panels last?

Donico Inter Co., Ltd. Photovoltaic panels (solar cells) have been widely applied all over the world as renewable energy resources. Since the average lifetime of PV panel is about 20 years, considerable amount of waste PV panels are accumulating every year.

Update Information

- Photovoltaic panels installed on power generation glass

- New glass photovoltaic panels

- Glass curtain wall plus photovoltaic panels

- Production of photovoltaic glass panels

- Can ordinary glass photovoltaic panels be used

- Photovoltaic panels are all made of glass

- Does photovoltaic glass emit radiation

- Bending of solar photovoltaic panels

- Can photovoltaic panels use half a battery

- Photovoltaic glass home power generation

- Photovoltaic glass is currently profitable

- Where to buy solar photovoltaic panels in Pyongyang

- Production of home solar photovoltaic panels

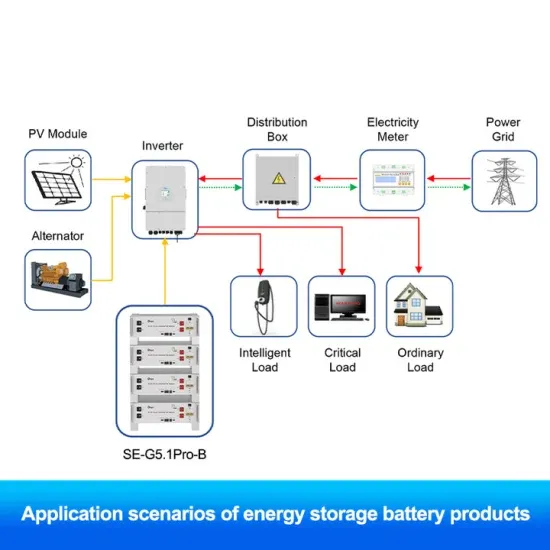

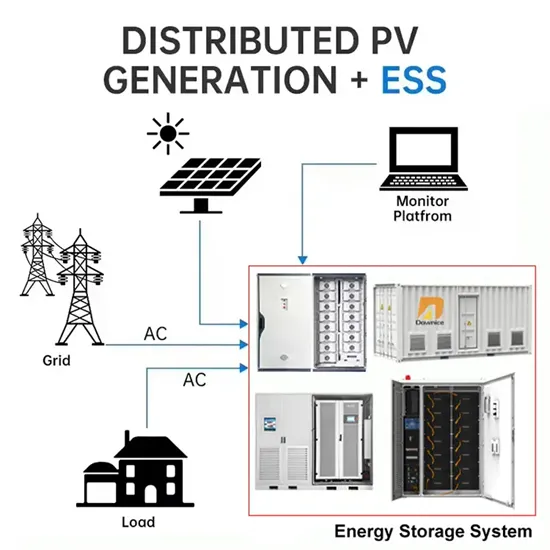

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.