Eaton EBC Installation and Operation Manual

Sep 2, 2024 · The Eaton® External Battery Cabinet (EBC) provides extended emergency short-term backup power for the 93E 80-200 kVA, 93E 300–400 kVA and 93PM 50-200kW UPS to

USER MANUAL BATTERY CABINET

Jul 28, 2025 · 1. TECHNICAL SPECIFICATIONS DC power cable connections. The M6 cable bolts should be torqued to 70 in-lbs. (8 Nm) and the M8 cable bolts should be tor ue to 150 in-lb

BATTERY CABINETS-Battery Cabinet-KEBOS POWER CO., LTD.-

Battery cabinets for all KEBOS UPS from 1KVA up to 1200KVA Power Range.The Battery cabinet is designed to house standard VRLA Batteries of capacity range from 17AH to 250AH.The

How to design an energy storage cabinet: integration and

Jan 3, 2025 · How to design an energy storage cabinet: integration and optimization of PCS, EMS, lithium batteries, BMS, STS, PCC, and MPPT With the transformation of the global

How to trigger power protection in battery cabinet

The Eaton® Integrated Battery Cabinet-Small (IBC-S) provides extended emergency short-time backup power for 93PM UPS systems to enhance the usability and reliability of the

Eaton 93E External Battery Cabinet installation manual

Sep 23, 2024 · Chapter 1 Introduction The Eaton® External Battery Cabinet (EBC) provides extended emergency short-term backup power for the 93E 20-30 kVA and 40-60 kVA UPS to

UPS5000-E

Jul 2, 2019 · battery cabinet be sealed after installation (before power-on) with baffle plates or plastic bags to prevent dust on the top of the battery cabinet or inside the battery cabinet. 8 5

UPS Battery Cabinets

Mar 5, 2025 · Versions and Model Numbers There are three distinct UPS battery cabinet versions within the ZincFive BC Series: BC 2, BC 2 - 300X, and BC 2 - 500. Each cabinet features a

-48 VDC Battery Cabinet Installation and User Manual

Apr 21, 2022 · Connect the power system''s battery cable terminated in an Anderson connector to the first battery cabinet''s battery cable terminated in a mating Anderson connector.

VertivTM Liebert® ITA2 Battery Cabinet

Feb 27, 2020 · Connect a single battery cabinet system. Refer to the illustration, "Cabling 3U Cabinets in Parallel," above, and connect the UPS-to-battery cable to Connectors A on each

Battery Cabinet BC29 Installation, Operation, & Maintenance

This manual provides detailed information on installation, operation, and maintenance of the BC29 Battery Cabinet, including safety precautions, system specifications, and battery replacement

RESS Li-ion Battery Installation Guide.cdr

Dec 6, 2023 · Installation Guide This guide provides guidance on the safe and effective installation and operation wall mounted Li-ion batteries. It also provides information on how to

Battery-Box LV Flex Lite

Nov 26, 2021 · This document contains safety information and instructions, scope of delivery, battery system overview, installation, electrical connection, commissioning, operation,

UBC87 Battery Cabinet Installation, Operation,

Jul 21, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

The Ultimate Guide to Power Cabinet: Everything You Need

Nov 1, 2024 · A power cabinet is a storage unit designed to house and protect charging equipment, power supplies, and devices. These cabinets are often built with durability in mind,

6 FAQs about [How to trigger the power cord of the battery cabinet]

How do I connect a battery cabinet to an ups?

Connect the DC+ and DC- cables to the DC+ and DC- terminals. Connect the power cables in the UPS. If more battery cabinets are part of the solution, connect all battery cabinets to the UPS according to the diagram below.

How do I connect a battery cabinet to a power system?

Procedure 1. Furnished with the battery cabinet are battery disconnect circuit breaker alarm lead assemblies. Refer to the power system installation manual to use these alarm leads to connect the battery cabinet battery disconnect circuit breaker alarm into the power system alarm circuits.

What is a battery lead cable?

Battery Leads Cables with connectors are provided on the associated power system and the battery cabinet to allow simple interconnections between a battery cabinet and the associated power system and between battery cabinets. The battery cabinet is designed to be daisy-chained together with additional battery cabinets.

How do you put a 4th Battery in a cabinet?

Place another inner battery spacer next to the third battery. 9. Set fourth battery in cabinet (being careful of the door fastener tabs hanging down) and attach the other end of the fast-on lugged cable to the negative terminal on the third battery (fast-on terminal).

How to connect a battery module with a data cable?

Data Cable Connection between battery modules Procedure: 1. Get rid of the terminal resistor at the “OUT” port of the battery module in which the “IN” port has been occupied. 2. Plug one side of the RJ45 connector to the “OUT” port. “IN” port of another battery module. “OUT” port there.

How do I install a VDC battery cabinet?

Set first battery in cabinet and attach the long lead (fast-on connector side marked positive) from the cabinet to the fast-on terminal on the positive terminal of the battery. See Figure 24. Facing left Facing right Facing left Vertiv™ NetSure™ 211 SERIES -48 VDC Battery Cabinet Installation & User Manual (Section 6023) Rev. L 23 Figure 24:

Update Information

- How to use ESS power base station in battery cabinet display cabinet

- How to install a battery cabinet dedicated to power supply

- How to connect the bridge to the battery cabinet ESS power base station

- How to match UPS power supply with battery cabinet

- How to customize battery cabinet power supply

- How to calculate the battery power of the energy storage cabinet

- How heavy is the 4G outdoor communication base station battery energy storage system cabinet

- How to make a good battery cabinet site

- Battery cabinet and distribution cabinet installation ESS power base station

- What are the battery cabinet communication power supply technologies

- How much does it cost to customize a battery cabinet and battery rack

- How much is the inverter battery discharge power

- Battery cabinet power capacity calculation formula

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

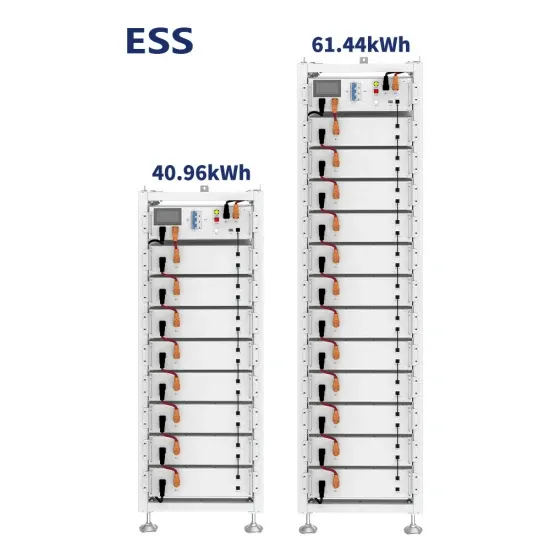

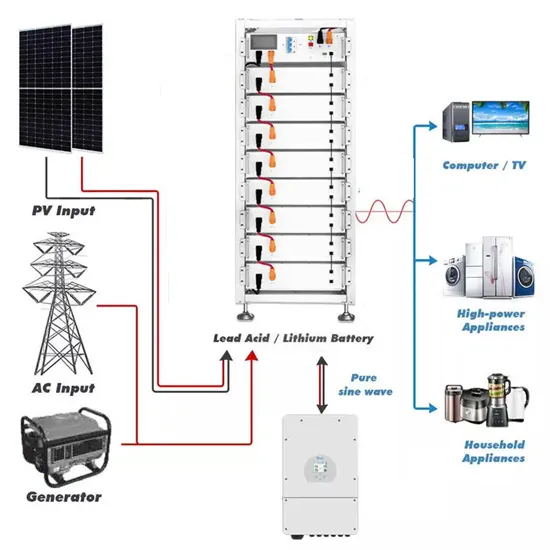

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.