Battery cabinet power calculation method formula

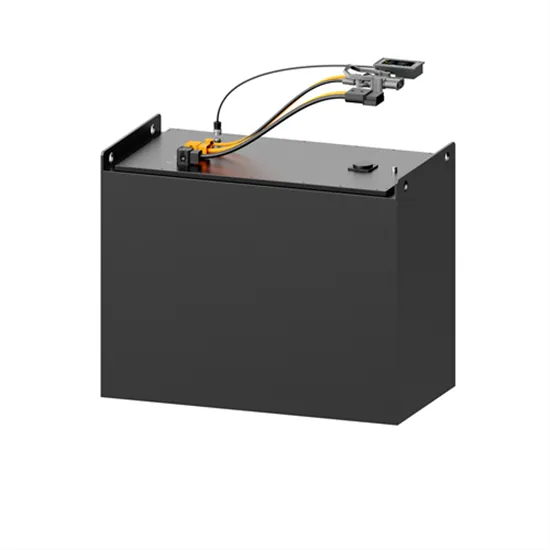

UBC80 Battery Cabinet C&C Power''''s UBC80 Battery Cabinet is a front terminal battery cabinet that typically supports system sizes from 80kVA-2,000kVA. The UBC80 is primarily used to

Power calculation formula for lithium battery cabinet

What is Lithium Battery C-rate and How to Calculate it? Understanding C-rate in Lithium Batteries. When dealing with lithium batteries, the C-rate is a crucial factor that dictates how fast a

Battery cabinet storage time calculation formula

Battery Capacity Calculator To calculate battery runtime, you can use the following formula: Battery Runtime (in hours) = Battery Capacity (in ampere-hours) / Device Power Consumption

Battery cabinet capacity calculation formula

Battery Charge Capacity and Energy Math The calculation of the battery capacity is a bit simpler than the calculation of battery energy. The formula I used is shown in Equation 2. Eq. 2:

Battery storage cabinet: how to determine its required capacity?

Jun 20, 2025 · Power * usage time = capacity. 800W*5+20W*5*8=4800WH, which is 4.8 KWH of electricity. This calculation method is used for storing electricity during the day and consuming

How to calculate the capacity of my power

May 15, 2025 · Learn how to calculate capacity for your power rectifier system by analyzing input voltage, output current, efficiency, and load requirements with

How to calculate battery room hydrogen ventilation

How to calculate hydrogen ventilation requirements for battery rooms.For standby DC power systems or AC UPS systems, battery room ventilation is calculated in accordance to EN 50272

Battery Capacity Calculator | True Geometry''s Blog

Mar 7, 2025 · Calculation Example: This calculator helps determine the required battery capacity (in Ampere-hours, Ah) and energy (in Watt-hours, Wh) to power a device for a specified

Battery Calculator – Calculate Battery Life and Capacity

Battery Calculator This battery calculator helps you to estimate the runtime for a device based on the battery capacity, voltage, device power consumption, and system efficiency. How to Use:

How to calculate the battery cabinet occupied by single

Hours Before we begin, we need to derive our useful equation. Let''''s determine our battery calculation formula with the definition of battery capacity: begin{equation} text{Battery Capacity

Battery cabinet calculation formula

How to Calculate A UPS Battery Backup In this guide, we will walk you through the step-by-step process of calculating the UPS battery backup capacity. We will cover important factors to

Calculation formula for new energy battery cabinet

The concept of battery efficiency became important as batteries were used more widely, requiring measurements to compare and improve energy storage technologies. Calculation Formula.

Battery cabinet capacity quick calculation formula

Battery Capacity Formula. The formula for calculating battery storage capacity is given below: Battery Capacity = Current (in Amperes) × Time (in hours) Where, Battery Capacity

UPS Battery Sizing Calculator – IEEE & IEC Guide with Formulas

Apr 20, 2025 · Accurately size your UPS battery with our IEEE and IEC compliant calculator for optimal backup power and reliability. Easy, fast, and precise.

Battery cabinet price calculation formula

External battery cabinet for 3PH UPS The external battery cabinets family is designed for standard VRLA batteries of capacity range from 24Ah to 105Ah (C10). The battery cabinets,

A Practical Guide to Calculating Home Battery Storage Capacity

Apr 3, 2025 · Understanding your daily energy consumption is the first step in determining the right home battery storage capacity. Start by listing all the appliances and devices you use

Battery cost calculation formula for battery swap cabinet

How to calculate battery size. After putting a lead-acid battery to use, you can calculate its remaining capacity using the following formula: B Pb - Remaining capacity of the lead-acid

Battery cabinet capacity quick calculation formula

The battery capacity calculator is an excellent choice if you want to know what battery capacity is or if you need to compute the properties of various batteries and compare them before

energy storage cabinet capacity calculation formula

Optimal Siting and Sizing of Battery Energy Storage Systems for The important characteristics of Li-ion batteries are their high capacity and energy per volume, fast charge and discharge,

Energy storage cabinet calculation formula

This paper proposes a method to determine the combined energy (kWh) and power (kW) capacity of a battery energy storage system and power conditioning system capacity (kVA) based on

Battery Capacity Calculator

Jul 18, 2025 · This all-in-one online Battery Capacity Calculator performs calculations using a formula that relates the battery voltage and capacity to the energy stored in the battery. You

Battery cabinet storage time calculation formula

Battery Runtime (hours) = (Battery Capacity (Ah) * Battery Voltage (V)) / Load Power (W) This formula takes into account the three key factors that influence battery runtime: battery

6 FAQs about [Battery cabinet power capacity calculation formula]

How do you calculate battery capacity?

Here, Power (W) represents the electrical power in watts, and Voltage (V) represents the operating voltage of the battery or system. Battery Capacity (Ah) = (Load Current (A) × Operating Time (h)) / Depth of Discharge (DoD) This equation calculates the required battery capacity in ampere-hours (Ah).

What is the formula to calculate battery capacity?

The following formula determines the battery capacity: Q = NC Ah (where N is the number of cells, C is the capacity of each cell in Ah, and Ah is the total capacity of the battery in Ampere-hours). The end of discharging test requires batteries to be recharged immediately.

What is battery load calculation?

Battery load calculation is a fundamental process used to determine the energy capacity needed from batteries to support electrical devices under various load conditions. This calculation ensures batteries are sized correctly for applications ranging from off-grid solar systems to uninterruptible power supplies (UPS).

How do you calculate power consumption?

Step 1: Identify all loads in the system (e.g., appliances, devices) and their power ratings in watts. Step 2: Add all power ratings together to obtain the total power consumption (W). Step 3: Determine the operating hours for each load to calculate daily energy consumption in watt-hours (Wh).

What is a typical battery voltage?

Common battery voltages are 12V, 24V, or 48V. Load Current (A): The current drawn by the device, calculated from the power consumption divided by the system voltage. Operating Time (h): The duration (in hours) for which the device is powered. This variable directly influences the total energy required.

Why is battery load calculation important?

Battery load calculation is essential for ensuring that the battery bank is sized properly to meet the energy needs of the system. It prevents under-sizing, which could lead to system failures, or over-sizing, which can be inefficient and costly.

Update Information

- What is the power capacity of the battery cabinet

- Battery cabinet heat calculation formula

- What does the outdoor energy storage power battery cabinet include

- Uninterruptible power supply battery cabinet function

- Can the battery cabinet be connected to the power supply all the time

- How to trigger the power cord of the battery cabinet

- The function of the power station battery cabinet is

- Battery cabinet base station power module power consumption

- Outdoor safe charging energy storage battery cabinet ESS power base station

- New energy battery cabinet base station power generation equipment

- Shared battery cabinet installation ESS power base station

- GZDW DC battery cabinet battery is out of power

- Praia communication base station lead-acid battery photovoltaic power generation capacity

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

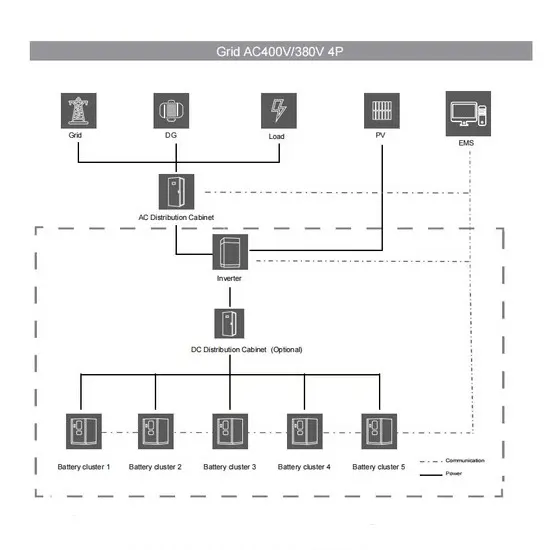

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.