Working principle of fan and water pump of energy

This article introduces the energy-saving principle of fans and water pumps, the principle of energy-saving renovation of central air-conditioning, and the control methods of

working principle of energy storage liquid cooling fan

Evaluation of a high-performance evaporative cooler-assisted open three-phase absorption thermal energy storage cycle for cooling Fig. 1 shows the working principles of the

electrical structure principle of container energy storage

A thermal management system for an energy storage battery container The typical types of energy storage systems currently available are mechanical, electrical, electrochemical,

Design principle of energy storage liquid cooling container

Design principle of energy storage liquid cooling container The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic

Operation principle of energy storage container

The operational principles of thermal energy storage systems are identical as other forms of energy storage methods,as mentioned earlier. A typical thermal energy storage system

Container Energy Storage: How It Powers the Future of Renewable Energy

Jun 1, 2025 · What''s the Big Deal with Container Energy Storage Systems? a standard shipping container, the same kind you''d see on cargo ships, quietly humming in a field. But instead of

working principle of energy storage system fan

Working Principle: Energy Storage: When there is excess electricity in the power grid (e.g., during periods of low demand or high renewable energy generation), the Flywheel Energy Storage

Principle of Energy Storage Fan: How It Works & Why It

The Science Bit: How Do Energy Storage Fans Actually Work? Imagine your fan moonlighting as a battery. The principle of energy storage fan tech hinges on capturing off-peak energy (cheap

Principle of fan used in energy storage equipment

energy storage is the change from water to steam. Technically this physical principle is used in so-called steam accumulators in power plants or industrial steam networks to avoid steam loss

INTERNAL STRUCTURE PRINCIPLE OF ENERGY STORAGE

What is battery energy storage system structure? Battery Energy Storage System Structure The storage device is controlled by the Monitors &Control module,also referred to as BMS (Battery

Energy storage container battery system principle

Battery energy storage systems are generally designed to be able to output at their full rated power for several hours. Battery storage can be used for short-term peak power and ancillary

Structural principle of lithium battery energy storage

What is the optimal design method of lithium-ion batteries for container storage? (5) The optimized battery pack structure is obtained, where the maximum cell surface temperature is

Integrated cooling system with multiple operating modes for

Apr 15, 2025 · Aiming at the problem of insufficient energy saving potential of the existing energy storage liquid cooled air conditioning system, this paper integrates vapor compression

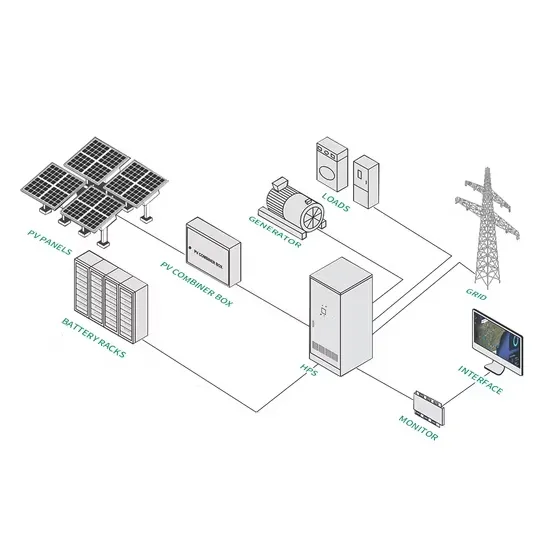

CONTAINER ENERGY STORAGE SYSTEM ALL YOU NEED TO

Energy storage container battery system principle A battery energy storage system (BESS), battery storage power station, battery energy grid storage (BEGS) or battery grid storage is a

How are energy storage containers configured? | NenPower

Aug 2, 2024 · Energy storage containers are configured using a variety of design principles and technical elements to optimize efficiency, safety, and usability. These configurations

Working principle of fan and water pump of energy

The working principle of a fan involves the application of voltage to the stator winding,which generates a pulsating type flux. There are two fluxes: one rotating in a clockwise direction and

New energy battery cabinet fan cooling principle

Can a battery container fan improve air ventilation? The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research.

Air cooling principle of energy storage cabinet

Does airflow organization affect heat dissipation behavior of container energy storage system? In this paper,the heat dissipation behavior of the thermal management system of the container

Principle and function of energy storage battery container

Battery Energy Storage Systems (BESS) play a crucial role in the modern energy landscape,providing flexibility,stability,and resilience to the power grid. Within these energy

Principle of explosion-proof fan of energy storage system

Modern hydrogen energy storage system accompaind by large solar power plant and wind turbine park in sunny summer afteroon light with blue sky and scattered clouds. 3d rendering. Axair

working principle of cooling fan for energy storage equipment

A thermal management system for an energy storage battery This shows that when all the fans are in the suction state, it leads to self-locking of airflow between the fans and the energy

working principle of cooling fan for energy storage equipment

Working principle of heat dissipating fan: The cooling fan is a new type of electromechanical integration fan, which uses the electromagnetic induction principle, uses the Holzer induction

What are the fans for energy storage? | NenPower

Oct 3, 2024 · What are the fans for energy storage? 1. Fans for energy storage play a crucial role by aiding in the dissipation of heat and enhancing efficiency,

A thermal management system for an energy storage battery container

May 1, 2023 · The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper innovatively proposes

Principle of container energy storage cabinet

In the realm of energy storage systems, the Battery Energy Storage System (BESS) container has emerged as a versatile and efficient solution. Central to the operation of a BESS container is

Working principle of energy storage axial flow fan

The working principle of Axial Flow Fan. When the impeller rotates, the gas enters the impeller axially from the air inlet, is pushed by the blades on the impeller to increase the energy of the

Designing a BESS Container: A Comprehensive Guide to Battery Energy

Apr 10, 2023 · The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

6 FAQs about [Principle of Energy Storage Container Fan]

Can a battery container fan improve air ventilation?

The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper innovatively proposes an optimized system for the development of a healthy air ventilation by changing the working direction of the battery container fan to solve the above problems.

How to improve airflow in energy storage system?

The aim of this strategy is to improve the fan state at the top so that the entire internal airflow of the energy storage system is in a circular state with the central suction and the two blowing ends. Optimized solution 4: fans 3 and 9 are set to suction state and the rest of the fans are set to blow state.

Does airflow organization affect heat dissipation behavior of container energy storage system?

In this paper, the heat dissipation behavior of the thermal management system of the container energy storage system is investigated based on the fluid dynamics simulation method. The results of the effort show that poor airflow organization of the cooling air is a significant influencing factor leading to uneven internal cell temperatures.

Does fan direction control improve cooling performance of battery packs?

Cooling performance of battery packs under different design options. In summary, the thermal management strategy based on fan direction control proposed in this paper has significant advantages when thermal management of battery pack groups in energy storage battery systems is performed.

How does airflow organization affect energy storage system performance?

The results of the effort show that poor airflow organization of the cooling air is a significant influencing factor leading to uneven internal cell temperatures. This ultimately seriously affects the lifetime and efficiency of the energy storage system.

How do I ensure a suitable operating environment for energy storage systems?

To ensure a suitable operating environment for energy storage systems, a suitable thermal management system is particularly important.

Update Information

- Principle and function of energy storage battery container

- Energy storage battery container refrigeration principle

- Nassau Hydrogen Fuel Cell Energy Storage Container

- How much does the Asian container energy storage fire fighting system cost

- Approximate cost of Bin energy storage container

- How much does a Bulgarian energy storage container cost

- What is a container energy storage company in Haiti

- Which standard should energy storage container refrigeration meet

- What are the Freetown container energy storage battery manufacturers

- Energy storage container system installation requirements

- United Arab Emirates Container Energy Storage System Company

- Eastern European container energy storage cabinet manufacturers

- Huawei Energy Storage Cabinet Container

Solar Storage Container Market Growth

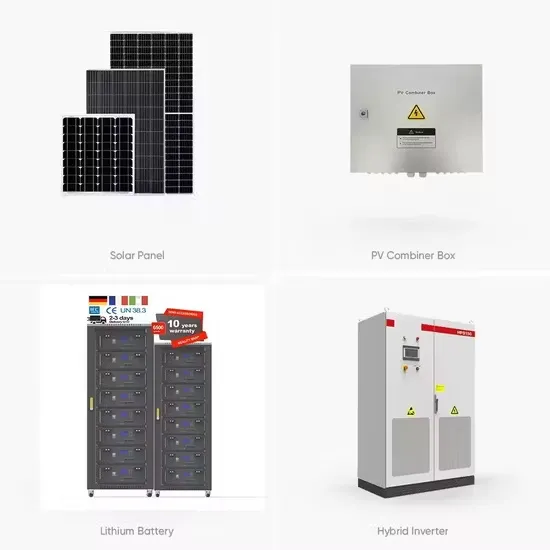

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.