Energy Storage Container Handling Techniques | Enerlution

Aug 17, 2024 · In conclusion, the handling techniques for energy storage containers encompass a broad range of activities, from transportation and installation to maintenance, safety, and

Energy Storage Container Design Information List: Key

Jul 20, 2021 · This article breaks down the energy storage container design information list into bite-sized pieces—perfect for engineers, project managers, and clean energy nerds who want

Selection of compatible metallic phase change materials and containers

Dec 1, 2020 · Selection of an appropriate mPCM for this application involves balancing the energy storage requirements to the alloy thermal properties and cost. The practicability of thermal

Energy Storage Container Technical Specifications

What is a battery energy storage system (BESS) container? This includes features such as fire suppression systems and weatherproofing, ensuring that the stored energy is safe and secure.

Requirements for energy storage container layout

1. Requirements and specifications: - Determine the specific use case for the BESS container. - Define the desired energy capacity (in kWh) and power output (in kW) based on the

Selection of container materials for modern planar sodium

Aug 1, 2017 · Sodium sulfur (NaS) cell is recognized as a promising candidate for advanced grid-scale large energy storage systems (ESS). In this work, we study the impacts of planar NaS

BESS Container Sizes: How to Choose the Right

Jun 5, 2025 · In this guide, we''ll explore standard container sizes, key decision factors, performance considerations, and how to select the best size for your

Electrical design for a Battery Energy Storage System (BESS) container

Mar 15, 2023 · Electrical design for a Battery Energy Storage System (BESS) container involves planning and specifying the components, wiring, and protection measures required for a safe

A multi-objective optimization approach for selection of energy storage

Jul 12, 2018 · In this study, a multi-criteria decision support framework which can be implemented using an a posteriori method for multi-objective optimization is proposed for the selection of

What special considerations are needed when using energy storage

By analyzing this data, operators can detect potential issues early and take preventive measures. Conclusion Deploying energy storage containers in cold regions presents a unique set of

What is the standard size of the energy storage container?

May 22, 2025 · When choosing energy storage containers, it is necessary to make the selection based on actual needs. For instance, if the equipment to be stored is large or in large

DS 5-33 Lithium-Ion Battery Energy Storage Systems

Mar 10, 2024 · Energy storage systems can be located in outside enclosures, dedicated buildings or in cutoff rooms within buildings. Energy storage systems can include some or all of the

What are the Essential Site Requirements for Battery Energy Storage

Nov 19, 2024 · Whate are the key site requirements for Battery Energy Storage Systems (BESS)? Learn about site selection, grid interconnection, permitting, environmental considerations,

Key Design Considerations for Energy Storage Containers

Apr 11, 2025 · The design of energy storage containers involves an integrated approach across material selection, structural integrity, and comprehensive safety measures. Choosing the right

Energy storage containers: an innovative tool in the green

Mar 13, 2024 · This article introduces the structural design and system composition of energy storage containers, focusing on its application advantages in the energy field. As a flexible and

How are energy storage containers produced? | NenPower

Mar 6, 2024 · 1. Energy storage containers are produced through a systematic approach that incorporates several stages:1) Design specifications, 2) Material selection, 3) Manufacturing

Energy Storage Container Installation Tips | Enerlution

Aug 4, 2024 · Energy storage containers have become a vital cog in our push towards a sustainable, efficient energy future. As our world continues to evolve and grow, the need for

Energy Storage Station Container Selection Criteria

The selection of the input-voltage, transformer, and converter power capacity of a large container energy storage power station, depends on several factors, including the size of

Requirements for energy storage container layout

battery energy storage system (BESS) container design seq and development of a containerized energy storage system. This system is typically used for large-scale energy storage

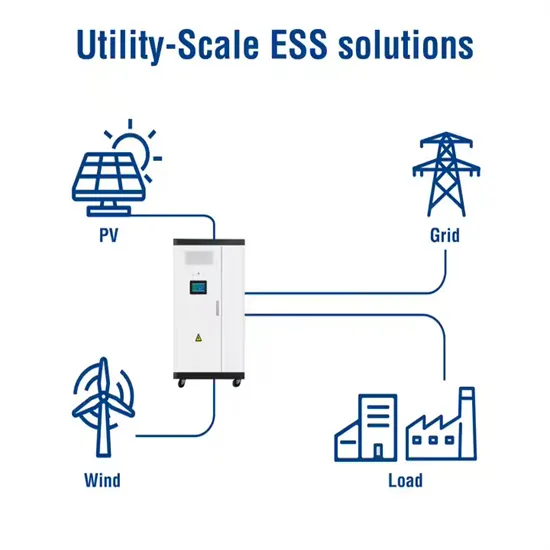

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

Integrated cooling system with multiple operating modes for

Apr 15, 2025 · The proposed energy storage container temperature control system provides new insights into energy saving and emission reduction in the field of energy storage.

Recent progress in phase change materials storage containers

Aug 1, 2020 · The potential for phase change materials (PCMs) has a vital role in thermal energy storage (TES) applications and energy management strategies. Nevert

6 FAQs about [Energy storage container selection]

How do I choose a containerized energy storage system?

Choosing between these sizes depends on project needs, available space, and future scalability. Regardless of format, each containerized energy storage system includes key components such as battery racks, BMS, EMS, cooling, and fire protection.

Do battery energy storage systems look like containers?

C. Container transportation Even though Battery Energy Storage Systems look like containers, they might not be shipped as is, as the logistics company procedures are constraining and heavily standardized. BESS from selection to commissioning: best practices38 Firstly, ensure that your Battery Energy Storage System dimensionsare standard.

How do I choose a Bess containerized battery energy storage system?

These containerized battery energy storage systems are widely used in commercial, industrial, and utility-scale applications. But one of the most important factors in choosing the right solution is understanding BESS container size — and how it impacts performance, cost, and scalability.

How important is a battery energy storage container?

Container size alone doesn’t determine a BESS system’s effectiveness — design and layout also matter. A well-structured battery energy storage container optimizes internal airflow, reduces cable loss, and ensures better thermal control.

Why is energy storage selection important?

This versatile, simple, and user-friendly method for energy storage selection is beneficial to the public and the development of energy storage systems, especially when energy storage systems become a type of household necessity in the future.

Can energy storage technology be used in centralized energy systems?

A series of case studies on the optimal selection of energy storage technology for the general grid-scale applications in centralized energy systems and rising applications related to distributed energy systems are carried out.

Update Information

- 300kwh energy storage container quotation

- Energy Storage Container Factory Operation Station

- Austrian Liquid Cooling Energy Storage Container Company

- What are the container energy storage businesses

- Energy Storage Container Transformer

- Energy storage charging container base station

- Turkmenistan energy storage explosion-proof container BESS

- Lithium battery energy storage container testing standards

- Testing standards for container energy storage batteries

- The latest solar energy storage container brand

- Boston Container Energy Storage

- How to fix the energy storage cabinet in the container

- What brands of energy storage battery container manufacturers are there

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.