CE-CF0530 Lithium Battery Cell Charging&Discharging Tester

CE-CF0530 adopts high-frequency power supply design to realize rapid charging and discharging maintenance of lithium battery cell. To be with battery cell capacity screening, SOC adjustment

How to Charge and Discharge Battery Test Equipment

Aug 14, 2023 · One typical application of a BTS is to charge and discharge a one-cell lithium-ion battery. Considering the voltage drop in the cable, the voltage required to do this is 0V to 5V.

Do We Need Lithium

Mar 12, 2025 · Explore whether lithium - battery charging and discharging equipment is essential for home energy storage. Learn about the role of such equipment in managing lithium - ion

Lithium battery charge/discharge aging equipment: technical

Lithium battery charging and discharging aging equipment by simulating the actual use of lithium batteries, lithium batteries for charging and discharging cycles, in order to assess their

Battery Charge And Discharge Curves

Jul 19, 2024 · The cycle test data of lithium-ion batteries is the accumulation of single charge and discharge data. Different single charge and discharge data can be extracted to make multiple

Explain Charging and Discharging of Lithium-Ion Battery

Feb 7, 2025 · In this post, you''ll learn how lithium-ion batteries work, the science behind charging and discharging, and best practices to extend their lifespan. Lithium-ion batteries power many

Effect of thermal characteristics of lithium-ion battery charging

With six fans, the system meets the thermal performance requirements of the battery pack and improves overall energy consumption. The research results offer valuable insights for

Lithium-Ion Cell Charging and Discharging

Aug 30, 2022 · Here we will explore the charging and discharging, and associated activities, for life cycle testing and for formation of lithium-ion cells, and how

How to Charge and Discharge Battery Test Equipment

Aug 14, 2023 · A battery test system (BTS) offers high voltage and current control accuracy to charge and discharge a battery. It is mainly used in manufacturing during production of the

DK-Tester | Professional Battery Testers & Testing Equipment

We focus on the research and development, design, production, and sales of high-precision battery testers, battery repair equipment, smart chargers, distributed charging facilities, and

Protection methods for lithium-ion battery charging and discharging

In addition to the charging and discharging circuit interface, the data acquisition communication interface is also prone to faults such as overcurrent. As described in ''JbT11143-2011 Lithium

Battery Testing System Manufacturer, Battery Charging and Discharging

Battery Testing System Supplier, Battery Charging and Discharging Test System, Battery Charging and Discharging Test Equipment Manufacturers/ Suppliers - Shenzhen Hongda New

Battery Charging Discharging Machine,battery Grading

100V 60A Battery Charging&Discharging Machine for High Power Battery 5V3A 512 Channel Li-ion Battery Charging Discharging Tester for Cylinder Cell and Pouch Cell Capacity Testing

Understanding Charging and Discharging of Lithium Ion Batteries

Feb 10, 2025 · Lithium-ion batteries have become a cornerstone of modern technology, powering everything from smartphones to electric vehicles. Understanding how these batteries charge

6 FAQs about [Lithium battery charging and discharging equipment]

Why is lithium ion battery discharge management important?

Discharging a lithium-ion battery allows it to supply power to devices. This process moves lithium ions and generates an electric current. Proper discharge management ensures efficiency, extends battery life, and prevents damage. How Does Discharging a Lithium-Ion Battery Work?

How do lithium ion batteries charge?

Lithium-ion batteries use specific charging techniques to prevent damage and ensure efficiency: The most widely used charging technique. Step 1: Constant current (CC) phase – Supplies steady current, raising battery voltage. Step 2: Constant voltage (CV) phase – Holds voltage steady while reducing current.

What happens if you don't charge a lithium ion battery?

Lithium-ion batteries power everything from smartphones to electric cars. But improper charging and discharging can shorten their lifespan. These rechargeable batteries store energy by moving lithium ions between electrodes. Over time, poor charging habits can lead to reduced performance, overheating, or even safety risks.

What is a battery cycle charge and discharge system?

Product description: The battery cycle charge and discharge system is a testing equipment for high voltage battery pack cycle life test, charge/discharge test, capacity test and charge-discharge efficiency test This tester is an energy feedback type, bidirectional and 8-channel power processing system controlled by computer.

How does temperature affect lithium ion charging & discharging efficiency?

Temperature significantly affects charging and discharging efficiency. Extreme heat or cold alters ion movement, reducing performance. Slows lithium-ion diffusion, increasing internal resistance. Reduces available capacity, causing voltage drops. Charging below freezing may cause lithium plating, permanently damaging the anode.

How do lithium-ion batteries work?

Lithium-ion batteries power many modern devices, from smartphones to electric vehicles. They store and release energy efficiently, making them the preferred choice for rechargeable power solutions. Understanding how they work starts with knowing their components and electrochemical processes.

Update Information

- Charging and discharging efficiency of lithium battery energy storage system

- Production of lithium battery equipment for energy storage

- What equipment will be used for lithium battery pack

- Effective charging and discharging power of energy storage battery

- Recommendation of lithium battery energy storage cabinet for charging pile in New Delhi

- Low temperature charging of lithium battery pack

- Lithium battery single string pack equipment

- Mobile energy storage charging and discharging equipment

- Charging and discharging data of household energy storage equipment

- Charging and discharging interval of energy storage equipment

- Cylindrical secondary lithium battery charging method

- Papua New Guinea Small Base Station Equipment Lithium Ion Battery Project

- What is the charging voltage of a 24V lithium battery pack

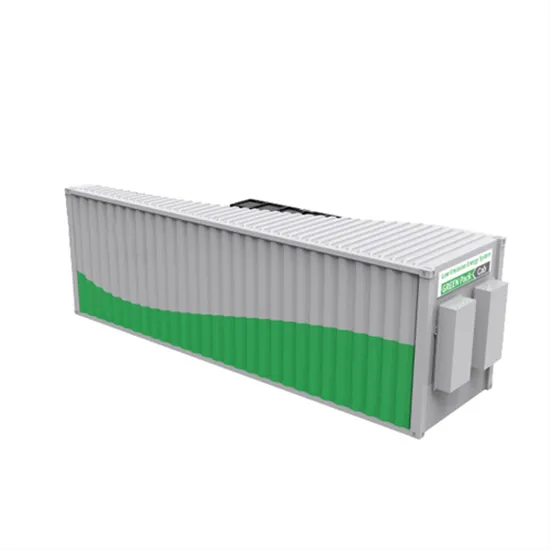

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.