Life Cycle Assessment of Monocrystalline Silicon Solar Cells

Feb 28, 2025 · Although monocrystalline silicon photovoltaic cells generate minimal pollution emissions during their operational phase, there are significant environmental concerns

What is the best material for solar photovoltaic monocrystalline

Jun 9, 2024 · The optimal choice in material for solar photovoltaic monocrystalline silicon wafers is undoubtedly high-purity silicon. The benefits of utilizing this material extend beyond mere

Monocrystalline Silicon

Jul 14, 2024 · Monocrystalline silicon panels have a longer energy payback time compared to other types, but their long lifespan and high efficiency offset this initial energy investment over

Progress in n-type monocrystalline silicon for high

May 21, 2024 · ABsTrACT Future high efficiency silicon solar cells are expected to be based on n-type monocrystalline wafers. Cell and module photovoltaic conversion efficiency increases are

Monocrystalline vs. Polycrystalline Solar Panels

Oct 11, 2024 · When it comes to residential solar installations, two panel types dominate the market - monocrystalline and polycrystalline solar panels. Both harness silicon photovoltaic

Monocrystalline solar cells and their efficiency

Apr 11, 2023 · After that, solar cells are linked together with metal connectors and assembled into solar panels. Learn about monocrystalline silicon solar cells

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Environmental impact of monocrystalline silicon photovoltaic

Jun 30, 2025 · The most promising N-type TOPCon monocrystalline silicon photovoltaic module is examined through the life cycle environmental impact assessment, and focus is placed on

Monocrystalline Perovskite Wafer/Thin Film for

May 1, 2024 · Demonstrated optoelectronic properties of HPs indicate that it could be a promising alternative to the silicon-based semiconducting industry. While the prerequisite of high

What are polycrystalline solar panels?

May 17, 2025 · Monocrystalline vs polycrystalline panels Monocrystalline solar panels are the higher-end alternative to polycrystalline panels. These panels are made from a single piece of

Free-standing ultrathin silicon wafers and solar cells through

May 7, 2024 · Here, authors present a thin silicon structure with reinforced ring to prepare free-standing 4.7-μm 4-inch silicon wafers, achieving efficiency of 20.33% for 28-μm solar cells.

Exploring Monocrystalline Solar Panels: A Comprehensive

Nov 9, 2023 · 2. Can SolarClue® explain the manufacturing process of monocrystalline solar cells, detailing how single-crystal silicon ingots are produced, sliced into wafers, and

The Pros and Cons of Monocrystalline Solar Panels

5 days ago · The manufacturing process for monocrystalline solar panels involves growing a single crystal of silicon, which is then sliced into thin wafers. This

Monocrystalline Silicon PV: 5 Advantages Over Alternatives

Jun 30, 2025 · Monocrystalline silicon PV offers 22-26% efficiency (vs 15-18% for polycrystalline), 25-year lifespan with <0.5% annual degradation. Its low-light performance generates 10%

Monocrystalline vs. Polycrystalline Solar Panels: 2024 Guide

Sep 19, 2024 · Average Cost The manufacturing process has the biggest impact on solar panel costs. Monocrystalline panels have a complex production process and use higher-quality

Progress in n-type monocrystalline silicon for high

May 21, 2024 · Future high efficiency silicon solar cells are expected to be based on n-type monocrystalline wafers. Cell and module photovoltaic conversion efficiency increases are

Life Cycle Assessment of Monocrystalline Silicon Solar Cells

Feb 28, 2025 · Pupin, P.C., et al.: Monocrystalline silicon solar cell for producing monocrystalline photovoltaic panels: a case study of Brazil. Energy Sources Part a-Recovery Utilization and

6 FAQs about [Monocrystalline silicon wafers and photovoltaic panel lifespan]

Will high efficiency solar cells be based on n-type monocrystalline wafers?

Future high efficiency silicon solar cells are expected to be based on n-type monocrystalline wafers. Cell and module photovoltaic conversion efficiency increases are required to contribute to lower cost per watt peak and to reduce balance of systems cost.

What are monocrystalline solar panels?

Monocrystalline solar panels are made with wafers cut from a single silicon crystal ingot, which allows the electric current to flow more smoothly, with less resistance. This ultimately means they have the highest efficiency ratings, longest lifespans, and best power ratings on the market, ahead of all other types of solar panels.

Why is monocrystalline silicon used in photovoltaic cells?

In the field of solar energy, monocrystalline silicon is also used to make photovoltaic cells due to its ability to absorb radiation. Monocrystalline silicon consists of silicon in which the crystal lattice of the entire solid is continuous. This crystalline structure does not break at its edges and is free of any grain boundaries.

How many m can a monocrystalline silicon cell absorb?

Monocrystalline silicon cells can absorb most photons within 20 μm of the incident surface. However, limitations in the ingot sawing process mean that the commercial wafer thickness is generally around 200 μm. This type of silicon has a recorded single cell laboratory efficiency of 26.7%.

What are crystalline silicon solar cells?

Crystalline silicon solar cells used crystalline silicon as the photovoltaic conversion material to convert solar energy into direct current electricity. At that time, there were two main types of silicon-based solar cells: monocrystalline silicon and polycrystalline silicon.

Are polycrystalline silicon solar cells better than MSSC?

Therefore, the conversion efficiency of polycrystalline silicon solar cells was usually lower than that of MSSC , and the consistency in optical, electrical, and mechanical properties of polycrystalline silicon was also inferior to that of monocrystalline silicon.

Update Information

- Solar photovoltaic panel monocrystalline silicon folding panel 400w

- 10w monocrystalline silicon photovoltaic panel

- Semi-transparent monocrystalline silicon photovoltaic panel price

- Benin monocrystalline silicon photovoltaic panel 580w

- Norwegian monocrystalline silicon photovoltaic panel manufacturer

- Photovoltaic panel monocrystalline silicon power

- Monocrystalline silicon photovoltaic panel sample

- Afghanistan monocrystalline silicon photovoltaic panel charging

- Peruvian Monocrystalline Photovoltaic Panel Company

- Monocrystalline photovoltaic panel standards

- Harare monocrystalline photovoltaic panel manufacturer

- Benefits of 315w monocrystalline silicon photovoltaic panels

- Rooftop monocrystalline silicon photovoltaic panels

Solar Storage Container Market Growth

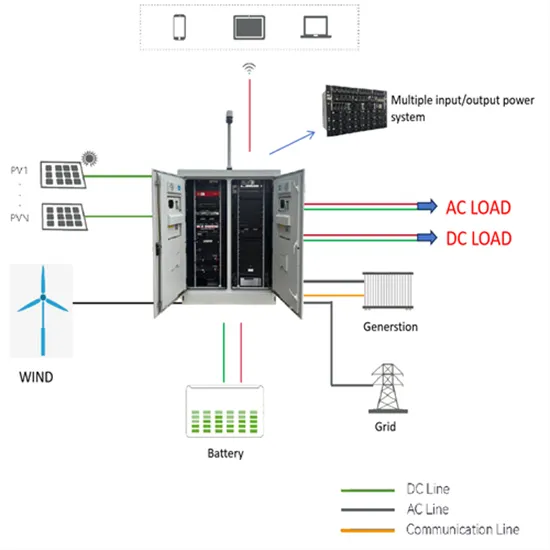

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.