Numerical simulation study on the impact of wind-blown

Jul 18, 2024 · The vast desert regions of the world offer an excellent foundation for developing the ground-mounted solar photovoltaic (PV) industry. However, the impact of wind-blown sand on

JA Solar PV Single-glass Modules Installation Manual

Jan 8, 2025 · The high level of load condition is applicable to the installation in harsher environmental conditions such as storm, heavy snow, etc: the maximum static load on the

Effects of Photovoltaic Module Materials and Design on

Feb 27, 2020 · Quasi-static structural finite-element models of an aluminum-framed crystalline silicon photovoltaic module and a glass-glass thin-film module were constructed

Mechanical Reliability Calculations for the Thin Specialty

Aug 24, 2023 · This study provides important design guidance to the Photovoltaic (PV) solar panel development efforts using the finite element based computations of the PV module

Investigation of static and dynamic mechanical loads on light-weight PV

Nov 15, 2024 · The findings indicate that a low inclination installation is preferable, and a glass-glass PV module with a 2.5 mm glass thickness can withstand static and dynamic mechanical

Trinasolar launches the Shield extreme climate solution,

Mar 31, 2025 · Trinasolar has launched its Shield extreme climate solution, which protects photovoltaic power plants from extreme weather such as hail, strong winds and snow storms.

Building-integrated photovoltaic applied Bi-facial photovoltaic

Jun 1, 2024 · Results of mechanical load testing and structural analysis confirmed that the commercial glass-to-glass photovoltaic module can withstand a maximum deformation (Ly) of

Solar for Home, Utility, and Commercial | Trina Solar US

Jun 21, 2022 · Snow exerts uneven pressure when it accumulates heavily on the module surface, especial y at the bottom Of the module, The non-uniform snow-load testing specifically

Performance Investigation of Tempered Glass‐Based

Oct 31, 2021 · Results indicated that, at solar irradiance of 900 W/m 2, the outputs from the fabricated polycrystalline and monocrystalline PV panels were 67.4 W and 75.67 W,

SPECIALTY THIN GLASS FOR PV MODULES:

Dec 4, 2023 · Glass has long been used for photovoltaic module covers and thin-film module substrates and superstrates. Typically this application uses standard or low-iron soda-lime

Simulation Investigation of the Wind Load of

Abstract. In this article, a simulation and evaluation of the mechanical stress exerted by the wind on photovoltaic panels is performed. The stresses of the solar cells in a PV module are

Second Glass Loading & Placement Machine | Solar Panel

Jan 16, 2025 · A second glass loading and placement machine is a high-precision dual-glass panel making machine. The glass machinery features short cycle time, high positioning

Effects of Photovoltaic Module Materials and Design on

Feb 27, 2020 · Quasi-static structural finite-element models of an aluminum-framed crystalline silicon photovoltaic module and a glass-glass thin-film module were constructed and validated

Types of BIPV systems: from solar glass to solar

Aug 15, 2023 · The solar cells are protected by heavy-duty, anti-slip, scratch and impact-resistant glass panels. The load-bearing capacity of the walk-on solar

SPECIALTY THIN GLASS FOR PV MODULES:

Dec 4, 2023 · iods has made glass a preferred material choice for these applications. Glass thickness for these applications can range from 2.5 to 4. mm for architectural uses to as thin

Glass/glass photovoltaic module reliability and

Aug 3, 2021 · Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with

Wind loading and its effects on photovoltaic modules: An

Jul 1, 2022 · In order to provide more data about the influence of the photovoltaic module aerodynamics on its constitutive structural elements, an interdisciplinary approach is

MA/Trinasolar launches the Shield extreme climate solution

Mar 31, 2025 · Trinasolar has launched its Shield extreme climate solution, which protects photovoltaic power plants from extreme weather such as hail, strong winds and snow storms.

Assessment of long term reliability of photovoltaic glass–glass modules

Apr 1, 2015 · Quantifying the reliability of photovoltaic (PV) modules is essential for consistent electrical performance and achieving long operational lifetimes.

Mechanical Stability of PV Modules: Analyses of the

Aug 5, 2024 · Different substructures and module designs are affected, framed and unframed modules, tracked and fixed systems. What all inquiries have in common, however, is that

Multi-objective evolutionary optimization of photovoltaic glass

Nov 1, 2023 · Optimized results of low-E semi-transparent amorphous-silicon photovoltaic glass applied on the façade show that the spatial daylight autonomy is increased to 82% with

Trina Solar Scores Big on PV Module Reliability Scorecard

Aug 28, 2017 · Dynamic mechanical load - Heavy loads of snow or high winds can cause pressure on the module''s glass that can lead to solder joint degradation or cell cracks. Damp

Experimental study on the influence of turbulence on hail

Aug 7, 2024 · However, research on the hail resistance of photovoltaic panels has predominantly focused on the isolated effects of hail impacts and wind loads, neglecting the coupling effects

Mechanical Reliability Calculations for the Thin Specialty

For Forward and Reverse wind load cases, the magnitude of the pressure load used was 2400 Pa, while, for Heavy wind load case, pressure magnitude of 5400 Pa was used (IEC 61646

6 FAQs about [Heavy pressure loading of photovoltaic glass]

Does glass superstrate provide mechanical rigidity of PV modules?

The glass superstrate provides the mechanical rigidity of the PV module since it comprises more than 72% of the module thickness and has a high mechanical stiffness of E = 73 GPa, which governs the deflection of the whole module. Fig. 19 shows the deflection across the PV module diagonal for PV modules with different glass stiffness.

Why do PV modules need a homogeneous mechanical load?

Various mechanical stresses can arise in PV modules due to manufacturing processes, transportation, handling during installation, wind, hail, snow, and thermo-mechanical loads. Numerous studies investigate a homogeneous mechanical load according to IEC 61215 which is crucial for the development of novel module designs.

Why is the thickness of a PV module important?

The thickness and the position of each material in the PV module are crucial for the reliability of the structure. The glass which is used as a front cover material, is the thickest part of the PV module. It is strong under compressive loading conditions and provides the mechanical rigidity of the entire structure.

What are the optimal design parameters for a glass-glass PV module?

This study finds the optimal design parameters of the support structure consisting of two C-Chanel that support the Glass-Glass PV module having thin glass on top and SLG at the bottom. Based on analysis described here, it was found that optimal channel location from free edges is close to L/5 that gives mechanical reliability of 0.99.

Does Si thickness affect the mechanical strength of PV modules?

The results showed that the Si thickness can play a critical role in the mechanical strength of PV modules. Although the Si thickness has a minor effect on the deflection of the PV module, the developed stresses increase significantly when the thickness is reduced.

What type of glass is used for a voltaic module?

voltaic module covers and thin-film module substrates and superstrates. Typically this application uses tandard or low-iron soda-lime-silica float glass with thickness 3.2 mm. Here we consider a specialty thin glass as ei er the substrate or superstrate of a dual-glass laminated TF PV module. A standard tempered 3.2 mm soda-lime-si

Update Information

- What is photovoltaic tempered glass

- Do shingled photovoltaic modules have glass

- Brazilian photovoltaic glass manufacturer

- Nicosia 2025 Photovoltaic Glass

- Demand for photovoltaic glass explodes

- Phosphorus silicon glass layer photovoltaic

- Uzbekistan Photovoltaic Glass Greenhouse Manufacturer

- Photovoltaic glass production plant in Mauritania

- Global Photovoltaic Glass Manufacturers Status

- Energy conversion of photovoltaic glass

- What are the effects of photovoltaic glass replacement

- Phnom Penh non-standard photovoltaic curtain wall glass components cadmium telluride

- Curtain wall photovoltaic glass production

Solar Storage Container Market Growth

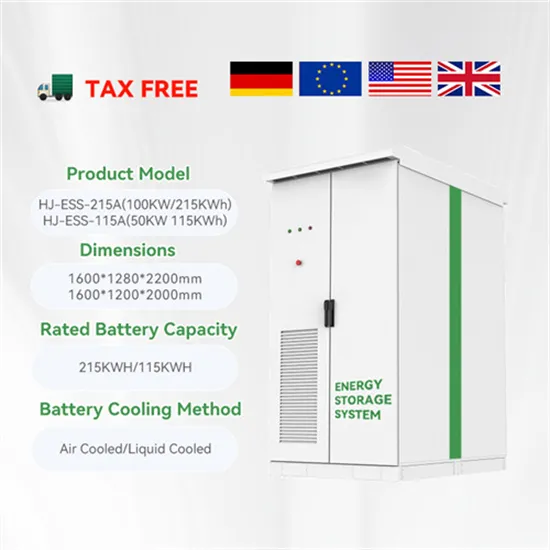

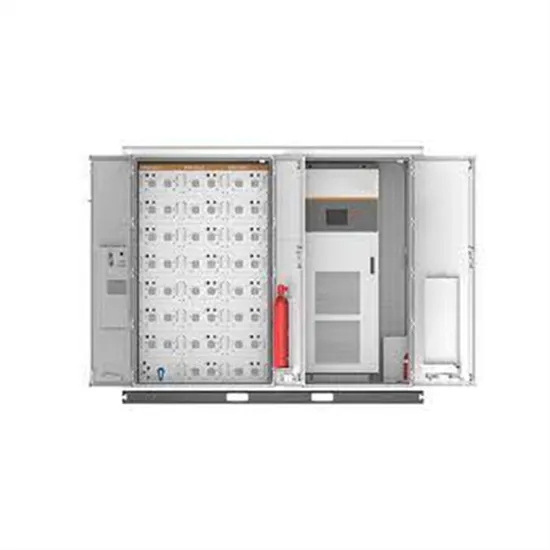

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.