Energy Storage with Lead–Acid Batteries

Jan 1, 2015 · As the rechargeable battery system with the longest history, lead–acid has been under consideration for large-scale stationary energy storage for some considerable time but

How to store lead acid batteries – BatteryGuy

May 3, 2024 · The ideal storage temperature is 50°F (10°C). In general terms the higher the temperature, the more chemical activity there is and the faster a sealed lead acid battery will

Lead batteries for utility energy storage: A review

Jul 13, 2017 · Lead batteries are very well established both for automotive and industrial applications and have been successfully applied for utility energy storage but there are a

How it is Made: The Lead Acid Battery – Part IX

Jun 26, 2024 · Dry charged lead acid batteries have a longer shelf life. They can be stored for a long time. They do not lose their charge. How Do They Work?

Polytetrafluoroethylene-infused dry processed enhancing lead

By improving the electrode materials and battery design, it is expected that lead‑carbon batteries will become even more competitive and widely adopted in various energy storage sectors [17,

Past, present, and future of lead–acid batteries

Aug 21, 2020 · When Gaston Planté invented the lead–acid battery more than 160 years ago, he could not have foreseen it spurring a multibillion-dollar

What are the Different Types of Lead-Acid Batteries?

Feb 26, 2025 · Lead-acid batteries are one of the most common and widely used types of rechargeable batteries. They have been around since the 19th century and continue to serve

2.60 S2020 Lecture 11: Batteries and Energy Storage

Feb 24, 2025 · The open circuit potential of a LiCoO2 battery is ~ 4.2 V. Specific energy is ~3-5X, specific power is 2X higher than lead-acid.~~~sfLCffbllllulsollo Table shows the characteristics

Dry Energy Storage Lead Acid Batteries: The Unlikely Hero of

Modern dry energy storage solutions use Valve-Regulated Lead Acid (VRLA) technology with absorbed glass mat separators. Unlike traditional flooded batteries, these:

Past, present, and future of lead–acid batteries

Aug 21, 2020 · Vojislav R. Stamenkovic W hen Gaston Planté invented the lead–acid battery more than 160 years ago, he could not have fore-seen it spurring a multibillion-dol-lar industry.

Lead Acid Battery: What''s Inside, Components, Construction,

Jan 1, 2025 · A lead-acid battery is a type of rechargeable battery that uses lead dioxide and sponge lead as electrodes, along with sulfuric acid as the electrolyte. It operates on the

MATERIAL SAFETY DATA SHEET MSDS

Feb 24, 2025 · Sulfuric Acid: Severe skin irritation, burns, damage to cornea may cause blindness, upper respiratory irritation. g, muscular aches and we cumulative and slow to

Lead-Acid Battery : Components, Reactions & Charging

The lead-acid accumulator remains one of the most widely used rechargeable batteries due to its cost-effectiveness, reliability, and high surge current capability. Although newer battery

The Difference Between Dry Batteries and Lead

May 23, 2024 · Dry batteries are ideal for single-use, low-drain applications, while lead-acid batteries are well-suited for rechargeable, high-demand applications

Lithium & Lead Acid Battery Manufacturer/Supplier | Discover Battery

3 days ago · What began as a regional battery distribution business in 1949 has grown into an international manufacturing and engineering company that provides leading-edge battery

Everything you need to know about lead-acid batteries

Apr 6, 2022 · The electrode is made of high-purity lead, which is thinner than in conventional lead-acid batteries. Alternatively, the plates can be made of a compound of lead and tin. This

Is a Lead Acid Battery a Dry Cell? Safety, Shelf Life, and Battery

Mar 19, 2025 · Lead-acid batteries are not dry cells. They are wet cells that use a liquid electrolyte solution. Dry cells, like alkaline and lithium batteries, contain a solid or gel-like electrolyte.

6 FAQs about [Dry Energy Storage Lead Acid Battery]

Are lead-acid batteries a good choice for energy storage?

Lead–acid batteries have been used for energy storage in utility applications for many years but it has only been in recent years that the demand for battery energy storage has increased.

How do dry charged lead acid batteries work?

The magic of dry charged lead acid batteries lies in their chemistry. When the sulfuric acid solution is added to the battery, it reacts with the lead plates. This produces lead sulfate and water. This reaction releases electrons. These electrons flow out of the battery and provide electrical power. We need this power to run our devices.

What are the disadvantages of dry charged lead acid batteries?

Dry charged lead acid batteries also have some disadvantages. One of the main ones is that they are quite heavy, which can be a drawback for portable applications. They also have a relatively short cycle life, which means they need replacing more often than some other types of batteries.

Are lead batteries sustainable?

Improvements to lead battery technology have increased cycle life both in deep and shallow cycle applications. Li-ion and other battery types used for energy storage will be discussed to show that lead batteries are technically and economically effective. The sustainability of lead batteries is superior to other battery types.

What is a lead acid battery?

Lead–acid batteries may be flooded or sealed valve-regulated (VRLA) types and the grids may be in the form of flat pasted plates or tubular plates. The various constructions have different technical performance and can be adapted to particular duty cycles. Batteries with tubular plates offer long deep cycle lives.

Can lead batteries be recycled?

A selection of larger lead battery energy storage installations are analysed and lessons learned identied. Lead is the most efcientlyrecycled commodity fi fi metal and lead batteries are the only battery energy storage system that is almost completely recycled, with over 99% of lead batteries being collected and recycled in Europe and USA.

Update Information

- Seoul Lead Acid Energy Storage Battery Pump

- Does the battery in the energy storage cabinet contain lead acid

- Rabat Energy Storage Lead Acid Battery Factory

- Baku Lead Acid Battery Energy Storage

- ASEAN Lead Acid Battery Energy Storage Container Supplier

- Huawei lead battery energy storage advantages

- Luxembourg lead carbon energy storage battery manufacturer

- Lead single flow energy storage battery

- Comoros aluminum acid energy storage battery application

- Taipei Aluminum Acid Energy Storage Battery

- Energy storage lithium iron phosphate and lead carbon battery

- Sao Paulo Brazil Smart Energy Storage Battery Customization Company

- Phnom Penh energy storage battery supplier

Solar Storage Container Market Growth

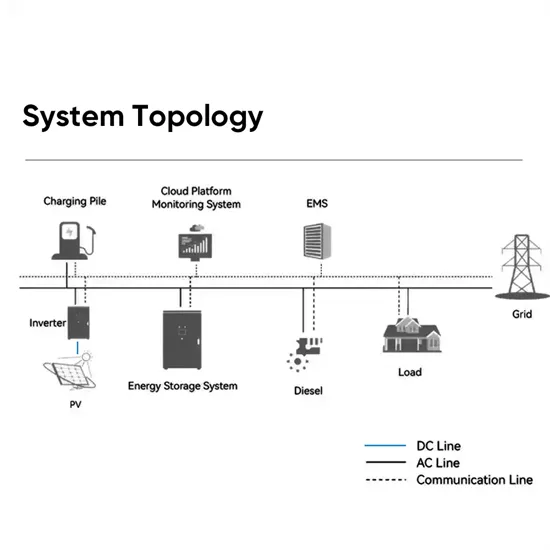

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

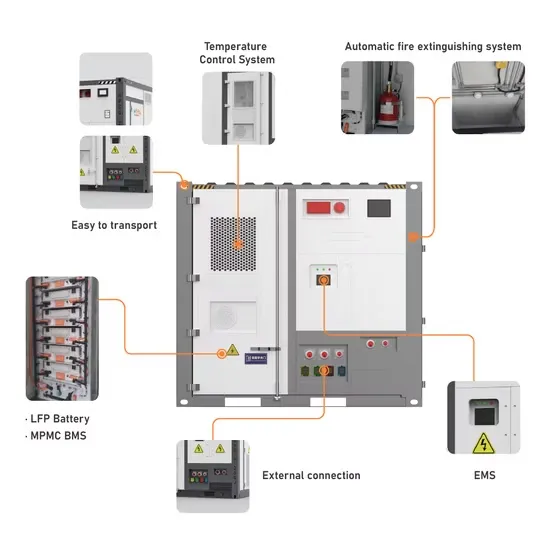

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.