Inverter Current Calculator, Formula, Inverter Calculation

5 days ago · Inverter Current Formula: Inverter current is the electric current drawn by an inverter to supply power to connected loads. The current depends on the power output required by the

Three-phase Grid-connected Converter

Jul 9, 2024 · It can regulate either inverter reactive power, inverter power factor, or inverter AC voltage. A reactive power -voltage (Q -V) droop control is added to the reactive power control

An advanced guide to Understanding DC to AC inverters

Apr 4, 2024 · Table of Contents While most homes have several appliances, very few residents know the difference between AC and DC power. Should people actually care if appliances use

MFDC Resistance Welding Inverter Controller

We design and supply different type of resistance welding controller is offen used to control medium frequency transformer.As the graphs imply, our MFDC welding controller can output

Dielectric Testing for Solar Inverters: A Comprehensive Guide

Dec 5, 2024 · Solar inverters are critical components in photovoltaic (PV) systems, responsible for converting the DC power generated by solar panels into usable AC power for electrical grids

AC ohmic loss from inverter to injection point

Nov 7, 2024 · The AC wiring losses may simply be defined by the distance between the inverter output and the injection point (or an eventual MV transformer), and the wire section. The

Is there a difference between MFDC and AC Resistance

2 days ago · Yes, there is a basic difference between the MFDC and AC transformers. MFDC transformers normally operate at 1000 Hz frequency and AC transformers operate at either 60

Resistance of an inverter from the DC link side?

Apr 8, 2015 · It would be 450V going to a boost converter, to a DC link capacitor, and then the inverter, followed by an LCL filter. Where D is duty, f_sw is switching frequency, Vripple is the

Insulation Resistance

Jun 3, 2019 · Inverter will check if the ISO is less than 100KΩ each time before it enters into operation mode and feed in the Grid. If the isolation resistance is less than 100 KΩ the inverter

Resistor solutions within inverter applications

Feb 4, 2019 · The image below shows a typical inverter topology with the various resistor requirements highlighted. These requirements may include filter resistors, snubbers, gate

System oscillations from negative input resistance at power

A switching regulator or a switching-mode amplifier, dc/dc converter, or dc/ac inverter can have a negative dynamic input resistance at the dc power input port. Frequently an LC decoupling

Parallel Inverter With Resistance Load

Mar 29, 2021 · This paper presents a method of calculating in terms of 2 parameters the characteristics of an inverter supplying a pure resistance load, and discusses the various

Resistance of an inverter from the DC link side?

Apr 8, 2015 · Hi, I''m trying to design a power inverter for solar panels. I''m out of school doing this on my own so any help would be appreciated. It would be 450V going to a boost converter, to

Resistive-feedback inverter. | Download Scientific Diagram

Download scientific diagram | Resistive-feedback inverter. from publication: A high IIP3 6.5 mW self-biased 0.3–3 GHz small area LNA | | ResearchGate, the professional network for scientists.

6 FAQs about [AC inverter resistance]

What is a DC AC inverter?

Traditionally, dc-ac inverters (also known as static inverters) use fixed dc sources to produce symmetrical ac output voltages at fixed or variable frequency or magnitude. The output ac voltage system can be of the single-phase or three-phase type at frequencies of 50, 60, and 400 Hz with a voltage magnitude range of 110 − 380 VAC.

How does an inverter work?

The inverter first converts the input AC power to DC power and again creates AC power from the converted DC power using PWM control. The inverter outputs a pulsed voltage, and the pulses are smoothed by the motor coil so that a sine wave current flows to the motor to control the speed and torque of the motor.

What is an example of an inverter?

For example, an inverter used to provide necessary changes in the frequency of the ac output is used to regulate the speed of an induction motor and is also used in a UPS system to produce a fixed ac frequency output when the main power grid system is out.

How does an inverter control a motor?

An inverter uses this feature to freely control the speed and torque of a motor. This type of control, in which the frequency and voltage are freely set, is called pulse width modulation, or PWM. The inverter first converts the input AC power to DC power and again creates AC power from the converted DC power using PWM control.

What happens if an inverter/charger has a small resistance difference?

Each inverter/charger contains an internal AC input contactor. These contactors are not always completely identical, they can have a small difference in their internal resistance, compared to the other contactors. This small resistance difference might result in the AC current being diverted from one unit to another.

What are the different types of AC inverters?

Medium- and high-power half-bridge and full-bridge switching devices using MOSFETs, IGBTs, and SiC- and GaN-based-devices are available as packages. Dc-ac inverters are used in applications where the only source available is a fixed dc source and the system requires an ac load such as in uninterruptible power supply (UPS).

Update Information

- Liquid-cooled AC inverter

- Inverter plus AC capacitor

- Inverter rated AC output power

- Inverter AC coupling mode

- How to achieve AC output of inverter

- AC DC dual-purpose inverter

- DC 110V to AC 220V inverter

- Fully automatic emergency AC DC inverter

- Does the inverter support AC

- DC to AC inverter design

- 220v AC voltage inverter

- Simple LC oscillation AC inverter

- Malaysia Penang AC Inverter

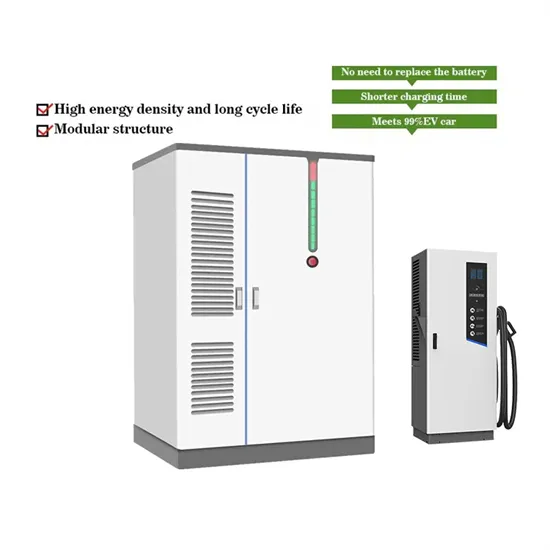

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.