Design, modeling, and validation of a 0.5 kWh flywheel energy storage

Nov 1, 2024 · The flywheel energy storage system (FESS) has excellent power capacity and high conversion efficiency. It could be used as a mechanical battery in the

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Flywheels store rotational kinetic energy in the form of a spinning cylinder or disc, then use this stored kinetic energy to regenerate electricity at a later time. The amount of

Rotor Design for High-Speed Flywheel Energy Storage

Sep 25, 2018 · More recently, flywheel systems were developed as true energy storage devices, which are also known as mechanical or electromechanical batteries. A remarkable example of

Flywheel Energy Storage System

Flywheel Energy Storage Systems (FESS) are defined as systems that store energy by spinning a rotor at high speeds, converting the rotor''s rotational energy into electricity. They utilize a high

Advancing renewable energy: Strategic modeling and

Nov 1, 2024 · Abstract This study introduces a hybrid energy storage system that combines advanced flywheel technology with hydrogen fuel cells and electrolyzers to address the

Kainat Riaz1, Syeda Fatima Imam1, Nida Ilyas1, Zia ul

Oct 19, 2022 · ABSTRACT Flywheel Energy Storage System (FESS) is an emerging technology with notable applications. To conduct analysis of flywheel''s rotors, cylindrical shape

Design of Flywheel Energy Storage System – A Review

Aug 24, 2024 · This paper extensively explores the crucial role of Flywheel Energy Storage System (FESS) technology, providing a thorough analysis of its components. It extens

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

A review of flywheel energy storage rotor materials and

Oct 19, 2023 · Although these reviews provide a comprehensive summary of flywheel energy storage, given the crucial role of flywheel rotor material and structure in flywheel system

Flywheel Energy Storage for Ancillary Services: A Novel Design

Aug 22, 2024 · With National Grid ESO introducing a suite of new Frequency Response Services for the GB electricity market, there is an opportunity to investigate the ability of low-energy

Design of Flywheel Energy Storage System – A Review

Aug 24, 2024 · This paper extensively explores the crucial role of Flywheel Energy Storage System (FESS) technology, providing a thorough analysis of its components. It extensively

Design and Research of a New Type of Flywheel Energy Storage

Feb 18, 2025 · The present article proposes a novel design for a zero-flux coil permanent magnet synchronous motor flywheel energy storage system, which exhibits a simple structure with

Design of Flywheel Energy Storage System – A Review

Aug 22, 2024 · This paper extensively explores the crucial role of Flywheel Energy Storage System (FESS) technology, providing a thorough analysis of its components. It extensively

Design of flywheel energy storage device with high specific energy

Jun 27, 2025 · The flywheel energy storage system is a way to meet the high-power energy storage and energy/power conversion needs. Moreover, the flywheel can effectively assist the

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · In this paper, state-of-the-art and future opportunities for flywheel energy storage systems are reviewed. The FESS technology is an interdisciplinary, complex subject that

Composite Flywheels for Energy Storage

Jun 7, 2017 · Energy storage flywheels are generally useful in power conditioning applications, i.e., when there is a mismatch between the power generated and the power required by the

The Status and Future of Flywheel Energy Storage

Jun 26, 2019 · This article describes the major components that make up a flywheel configured for elec-trical storage and why current commer-cially available designs of steel and composite

Design, Fabrication, and Test of a 5 kWh Flywheel Energy

Oct 28, 2021 · Abstract The Boeing team has designed, fabricated, and is currently testing a 5 kWh / 100 kW Flywheel Energy Storage System (FESS) utilizing the Boeing patented high

Energy Storage Flywheel Rotors—Mechanical Design

The present entry has presented an overview of the mechanical design of flywheel energy storage systems with discussions of manufacturing techniques for flywheel rotors, analytical modeling

Design and Analysis of a Unique Energy Storage Flywheel

Apr 1, 2015 · Energy storage is becoming increasingly important with the rising need to accommodate the energy needs of a greater population. Energy storage is especially

General Design Method of Flywheel Rotor for Energy Storage

Jan 1, 2012 · Flywheel rotor design is the key of researching and developing flywheel energy storage system.The geometric parameters of flywheel rotor was affected by much restricted

Rotor Design for High-Speed Flywheel Energy Storage

Sep 25, 2018 · Contemporary flywheel energy storage systems, or FES systems, are frequently found in high-technology applications. Such systems rely on advanced high-strength materials

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Energy storage flywheels are usually supported by active magnetic bearing (AMB) systems to avoid friction loss. Therefore, it can store energy at high efficiency over a long

6 FAQs about [Flywheel energy storage design]

Is flywheel storage energy system a new technology?

Flywheel storage energy system is not a new technology; however, the deep interest in applying its principle in power system applications has been greatly increasing in the recent decades.

What is a high-speed flywheel energy storage system?

Modern high-speed flywheel energy storage systems have a wide range of applications in renewable energy storage, uninterrupted power supplies, transportation, electric vehicle charging, energy grid regulation, and peak shaving.

What is flywheel energy storage system (fess)?

but lower energy density, longer life cycles and comparable efficiency, which is mostly attractive for short-term energy storage.Flywheel energy storage systems (FESS) have been used in uninterrupted power supply (UPS) –, brake energy recovery for ra

What are the components of a flywheel energy storage system?

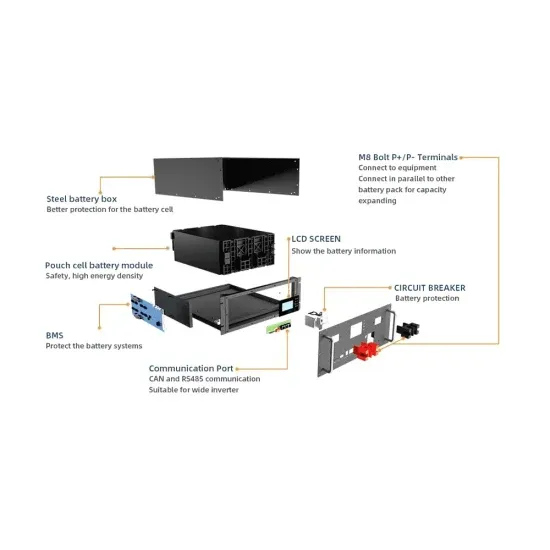

The key components of the flywheel energy storage system [6, 7] comprise the flywheel body , magnetic levitation support bearings [9, 10, 11], high-efficiency electric motors [12, 13, 14, 15, 16, 17, 18], power electronic conversion equipment, and vacuum containers.

Are flywheel-based hybrid energy storage systems based on compressed air energy storage?

While many papers compare different ESS technologies, only a few research [152,153] studies design and control flywheel-based hybrid energy storage systems. Recently, Zhang et al. present a hybrid energy storage system based on compressed air energy storage and FESS.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Update Information

- Flywheel system energy storage device composition

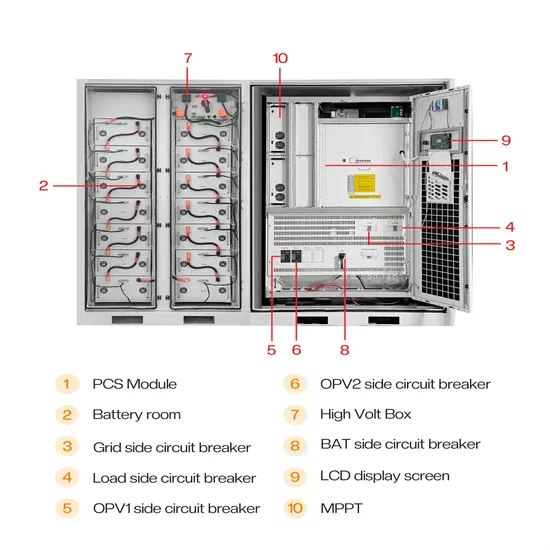

- Design of power plant with energy storage station

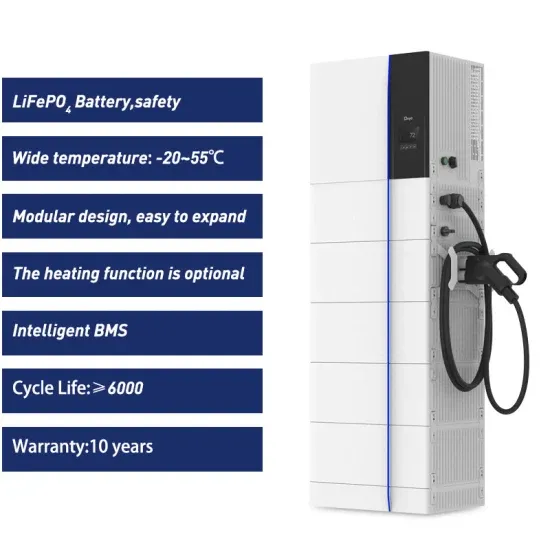

- Household Energy Storage Industrial Design Solution

- Enterprise energy storage power station design plan

- Containerized energy storage cabin design

- Containerized energy storage solution design

- Energy storage container base station design

- Energy storage equipment design in Chiang Mai Thailand

- Outdoor energy storage battery cabinet design

- Energy storage container house design

- Typical design scheme of chemical energy storage

- Energy storage system ground power station design scheme

- London CRRC Flywheel Energy Storage Project

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.