Evaluation of a novel indirect liquid-cooling system for energy storage

Feb 15, 2025 · Higher cooling water flow velocity and lower cooling temperature are beneficial for the temperature uniformity of battery pack, with a cooling temperature controlled below 35 °C.

JinkoSolar Provides 6MWh Liquid Cooling ESS in Taishan

Jan 9, 2025 · In the pursuit of technological excellence, Jin-koSolar always adheres to the principle of safety first. Energy storage safety upgrades are imminent, and liquid cooling

Immersed liquid cooling energy storage system

What is a single phase immersion cooling fluid? Single phase immersion cooling fluids can come under several categories which include: hydrofluoroethers,hydrocarbons,silicon oils and

SolaX ESS-TRENE | All-In-One C&I ESS Cabinet | 125kW

5 days ago · The SolaX ESS-TRENE is an all-in-one C&I energy storage cabinet, in liquid cooling model. Equipped with high-performance LFP cells, advanced energy management, and robust

Thermodynamic analysis of isothermal compressed air energy storage

Dec 1, 2023 · Abstract Compressed air energy storage (CAES) is regarded as an effective long-duration energy storage technology to support the high penetration of renewable energy in the

JinkoSolar liquid-cooling ESS enables Hangzhou First

Jan 9, 2025 · With the rapid development of the domestic energy storage market, downstream energy stor-age integrators and end-user business customers are accelerating the deployment

Liquid Cooled Battery Energy Storage Systems

Jan 28, 2024 · In the ever-evolving landscape of battery energy storage systems, the quest for efficiency, reliability, and longevity has led to the development of more innovative

Stockholm liquid cooling energy storage costs

This paper introduces, describes, and compares the energy storage technologies of Compressed Air Energy Storage (CAES) and Liquid Air Energy Storage (LAES). Given the significant

What is Immersion Liquid Cooling Technology in Energy Storage

Dec 11, 2024 · Immersion liquid cooling technology is an efficient method for managing heat in energy storage systems, improving performance, reliability, and space efficiency.

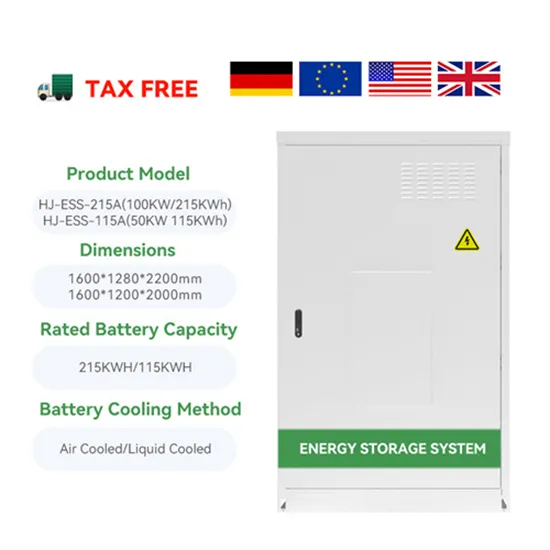

Commercial & Industrial Liquid Cooling Energy Storage System | GSL ENERGY

GSL Energy''s Liquid Cooling Energy Storage System, perfect for farms, factories, commercial buildings, and microgrids. Supports up to 10 units in parallel and offers Southeast Asia and

A novel perspective on the performance analysis and design

Oct 1, 2020 · A schematic of the injection cooling process is shown in Fig. 1. It is seen that the insulated storage vessel is partially filled with the liquid to be cooled to accommodate the

Experimental studies on two-phase immersion liquid cooling

Nov 30, 2023 · The thermal management of lithium-ion batteries (LIBs) has become a critical topic in the energy storage and automotive industries. Among the various cooling methods, two

What Is ESS Liquid Cooling?

2 days ago · Liquid cooling enhances energy storage systems. It does this by managing heat well. This improves efficiency, reliability, and lifespan. This article will explore the benefits,

Why Choose a Liquid Cooling Energy Storage System? | GSL Energy

Jul 7, 2025 · Against the backdrop of accelerating energy structure transformation, battery energy storage systems (ESS) are widely used in commercial and industrial applications, data

JinkoSolar to Deliver SunGiga C&I Storage System for

Jan 8, 2025 · Increased safety, lower LCOE, easier integration, and operation & maintenance (O&M) costs, are always major concerns for stakeholders when choosing an ideal C&I ESS.

Revolutionizing Energy Storage: Liquid-Cooled Systems for

Mar 1, 2024 · The integration of liquid cooling technology into industrial and commercial energy storage systems represents a significant stride toward efficiency, reliability, and sustainability.

A review on the liquid cooling thermal management system

Dec 1, 2024 · Liquid cooling provides up to 3500 times the efficiency of air cooling, resulting in saving up to 40% of energy; liquid cooling without a blower reduces noise levels and is more

Liquid Cooling Energy Storage: Why It''s the Coolest

Jan 21, 2025 · Enter liquid cooling energy storage —a game-changer that''s redefining efficiency, safety, and sustainability in the energy sector. In this blog, we''ll dive into why this technology is

Liquid-gas heat transfer characteristics of near isothermal

Nov 15, 2023 · Isothermal compressed air energy storage (I-CAES) could achieve high roundtrip efficiency (RTE) with low carbon emissions. Heat transfer enhancement is the key to achieve I

Evaluation of a novel indirect liquid-cooling system for energy storage

Feb 15, 2025 · To achieve superior energy efficiency and temperature uniformity in cooling system for energy storage batteries, this paper proposes a novel indirect liquid-cooling system based

Integrated cooling system with multiple operating modes for

Apr 15, 2025 · Aiming at the problem of insufficient energy saving potential of the existing energy storage liquid cooled air conditioning system, this paper integra

Why More and More Energy Storage Companies Are Choosing Liquid Cooling

Dec 13, 2024 · Learn how liquid cooling outperforms air cooling in terms of efficiency, stability, and noise reduction, making it ideal for large-scale, high-energy-density storage solutions.

Liquid Cooling in Energy Storage: Innovative Power Solutions

Jul 29, 2024 · Liquid cooling systems use a liquid coolant, typically water or a specialized coolant fluid, to absorb and dissipate heat from the energy storage components. The coolant circulates

Boyd''s Liquid Cooling Solutions for Electric Vehicles

May 26, 2023 · Creating Competitive Advantage in eMobility Applications This paper addresses current and upcoming trends and thermal management design challenges for Electric Vehicles

What Are The Benefits Of ESS Liquid Cooling?

Aug 15, 2025 · Discover the benefits of ESS liquid cooling for energy storage systems, including enhanced thermal management, increased efficiency, and extended component lifespan.

Research progress in liquid cooling technologies to enhance

Aug 29, 2023 · In terms of liquid-cooled hybrid systems, the phase change materials (PCMs) and liquid-cooled hybrid thermal management systems with a simple structure, a good cooling

Liquid Cooling Energy Storage: The Next Frontier in Energy Storage

Apr 5, 2025 · Liquid-cooled energy storage is becoming the new standard for large-scale deployment, combining precision temperature control with robust safety. As costs continue to

液冷散热技术在电化学储能系统中的研究进展

Apr 1, 2024 · The findings indicate that liquid cooling systems offer significant advantages for large-capacity lithium-ion battery energy storage systems. Key

6 FAQs about [Liquid Cooling Energy Storage Injection]

Why is liquid cooling important for energy storage systems?

Liquid cooling systems provide many benefits for Energy Storage Systems (ESS). They improve thermal management and efficiency compared to air cooling. One key benefit is better thermal management. Liquid cooling can absorb and transfer heat well. This improves temperature regulation. It is critical for keeping ESS components safe and at their best.

What is liquid injection oil cooling?

Liquid injection oil cooling is that a small amount of refrigerant liquid from high pressure receiver is injected into the screw compressor just before the discharge port of the compressor. The liquid refrigerant evaporated and the mixture of the oil and the refrigerant vapor is cooled down to an acceptable temperature.

What is liquid cooling technology?

Liquid cooling technology offers a sophisticated solution for managing the thermal loads in ESS. Traditional air cooling relies on fans to dissipate heat. In contrast, liquid cooling uses pipes to circulate a coolant. The coolant absorbs and transfers heat away from critical components. This method has better thermal conductivity.

How does a liquid cooling system work?

A liquid cooling system has key elements. These are cold plates, coolant distribution units, pumps, and heat exchangers. These parts work together to move a coolant. This fluid is usually water or a water-glycol mix. It flows through the ESS, taking heat from critical parts. It then moves it to a heat exchanger where it is dissipated.

Does JinkoSolar use liquid cooling?

JinkoSolar uses liquid cooling. It keeps the ESS stable by preventing hotspots and reducing the risk of thermal runaway. This not only enhances the safety of the system but also optimizes its performance. Trumonytechs is a leader in liquid cooling for Energy Storage Systems (ESS).

Which companies use liquid cooling technology in their ESS?

Several leading companies have adopted liquid cooling technology in their ESS. For instance, Sungrow is a big player in renewable energy. They use advanced liquid cooling in their ESS. This improves thermal management and system reliability. JinkoSolar is known for its innovative solar products.

Update Information

- Huawei energy storage liquid cooling pack

- Liquid Cooling Energy Storage Container Price in Cebu Philippines

- Energy storage liquid cooling selection

- Togo Liquid Cooling Energy Storage Cabinet

- Desert Energy Storage Liquid Cooling

- Germany liquid cooling energy storage prices

- Djibouti Energy Storage Liquid Cooling Container Factory Operation

- Which energy storage container liquid cooling manufacturers are there

- Danish liquid cooling energy storage project

- St George Liquid Cooling Energy Storage Cabinet Manufacturer

- Huawei Luxembourg Energy Storage Liquid Cooling

- Liquid cooling and air cooling structure design of energy storage system

- Venezuela energy storage liquid cooling outdoor cabinet manufacturer

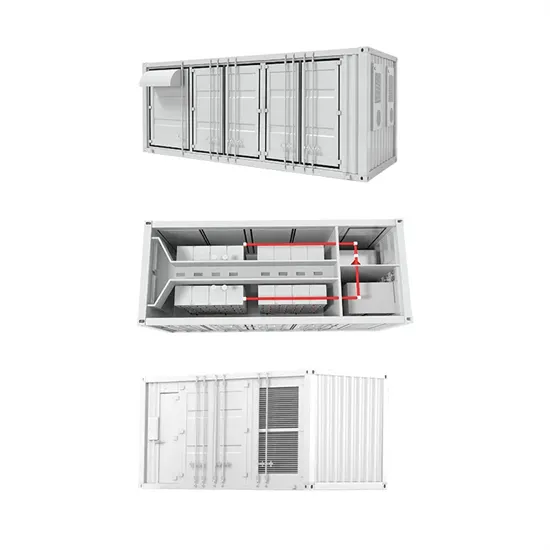

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.