2.5MW/5MWh Liquid-cooling Energy Storage System

Oct 29, 2024 · The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20''GP container, thermal management system, firefighting system, bus unit, power distribution unit,

Revolutionizing Energy Storage: Liquid-Cooled Systems for

Mar 1, 2024 · The integration of liquid cooling technology into industrial and commercial energy storage systems represents a significant stride toward efficiency, reliability, and sustainability.

What is Immersion Liquid Cooling Technology in Energy Storage

Dec 11, 2024 · Immersion liquid cooling technology is an efficient method for managing heat in energy storage systems, improving performance, reliability, and space efficiency.

Integrated cooling system with multiple operating modes for

Apr 15, 2025 · Aiming at the problem of insufficient energy saving potential of the existing energy storage liquid cooled air conditioning system, this paper integra

Why Choose a Liquid Cooling Energy Storage System? | GSL Energy

Jul 7, 2025 · Against the backdrop of accelerating energy structure transformation, battery energy storage systems (ESS) are widely used in commercial and industrial applications, data

Air Cooling vs. Liquid Cooling of BESS: Which One Should

Aug 15, 2024 · Environmental Impact The choice between air cooling and liquid cooling can also be influenced by environmental factors. Liquid cooling systems, while more efficient, may

Study on uniform distribution of liquid cooling pipeline in

Mar 15, 2025 · Designing a liquid cooling system for a container battery energy storage system (BESS) is vital for maximizing capacity, prolonging the system''s lifespan, and improving its

The United Arab Emirates CIMC Energy Storage Project:

Jul 26, 2022 · Why This Project Matters to Global Energy Transition Imagine turning the UAE''s scorching sunlight into a 24/7 power source – that''s exactly what the United Arab Emirates

Liquid Cooling Energy Storage: The Next Frontier in Energy Storage

Apr 5, 2025 · Liquid-cooled energy storage is becoming the new standard for large-scale deployment, combining precision temperature control with robust safety. As costs continue to

Desert BESS project in Chile: innovation in energy storage

Sungrow says that the PowerTitan offers C5 corrosion resistance, IP65 protection against wind and sand, intelligent liquid cooling, and a smart operation and maintenance system.

How Energy Storage Liquid Cooling Works: A Cool Solution

Why Liquid Cooling Is Stealing the Spotlight in Energy Storage thousands of batteries working overtime in a storage facility, generating enough heat to fry an egg. Enter energy storage liquid

Cooler Than the Desert: Inside Kortrong''s Heat-Defying Energy Storage

Jul 18, 2025 · The company''s liquid-cooled energy storage system dynamically adjusts coolant flow and temperature in real time based on detected temperature differentials. Complemented

Integrated solar-powered freeze desalination and water

Feb 26, 2025 · Freeze desalination is an efficient method of desalting brackish water. Cold energy from ice melting is recovered for air conditioning. The hydrogen storage enables continuous

How Do Advanced Liquid Cooling Rack Batteries Enhance Desert

Jun 15, 2025 · Advanced liquid cooling rack batteries optimize energy storage in desert solar farms by regulating temperatures in extreme heat. These systems use coolant circulation to

Energy storage cooling system

Dec 8, 2024 · Therefore, the liquid cooling system is more conducive to maintaining the performance and life cycle of the battery, and by increasing the operating hours and extending

Energy Storage Liquid Cooling System Market

What are the primary market drivers accelerating adoption of liquid cooling systems in energy storage applications? Rising demand for battery energy storage systems (BESS) in renewable

Integrated solar-powered freeze desalination and water

Feb 26, 2025 · Comparatively analyze the performance of various energy storage solutions, including pumped hydro, compressed air, liquid air, and hydrogen (other than proton exchange

Efficient Cooling System Design for 5MWh BESS Containers:

Aug 10, 2024 · Discover the critical role of efficient cooling system design in 5MWh Battery Energy Storage System (BESS) containers. Learn how different liquid cooling unit selections impact

Thermal Management Technology of 1MWh BESS Energy Storage

Dec 27, 2024 · The 1MWh Battery Energy Storage System (BESS) is a crucial component in modern energy storage applications. As the capacity and power of BESS increase, thermal

Principles of liquid cooling pipeline design

3 days ago · This article will introduce the relevant knowledge of the important parts of the battery liquid cooling system, including the composition, selection

Energy Storage Liquid Cooling Pipeline Market

Feb 25, 2025 · Key Demand Drivers for Energy Storage Liquid Cooling Pipelines in Commercial and Industrial Applications The surge in energy storage system (ESS) deployments,

6 FAQs about [Desert Energy Storage Liquid Cooling]

What is a 5MWh liquid-cooling energy storage system?

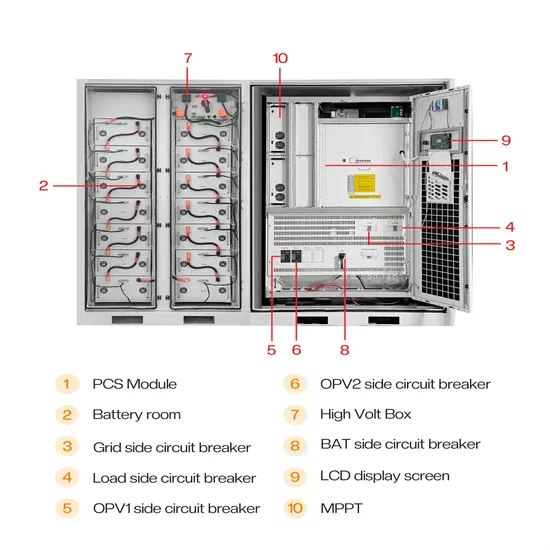

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20’GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring harness, and more. And, the container offers a protective capability and serves as a transportable workspace for equipment operation.

What is a liquid cooling thermal management system?

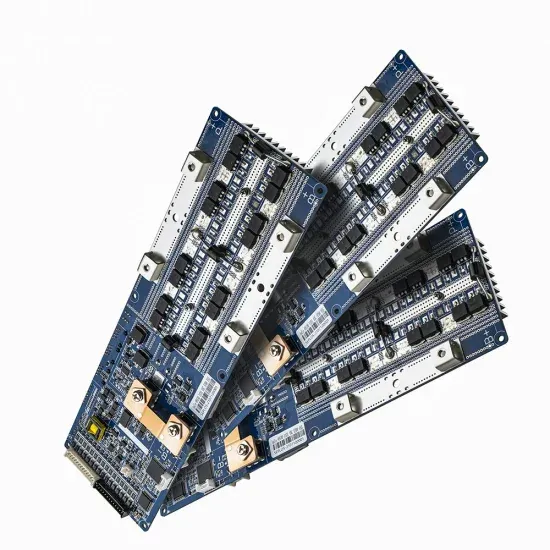

The liquid cooling thermal management system for the energy storage cabin includes liquid cooling units, liquid cooling pipes, and coolant. The unit achieves cooling or heating of the coolant through thermal exchange. The coolant transports heat via thermal exchange with the cooling plates and the liquid cooling units.

What is a liquid cooling unit?

The product installs a liquid-cooling unit for thermal management of energy storage battery system. It effectively dissipates excess heat in high-temperature environments while in low temperatures, it preheats the equipment. Such measures ensure that the equipment within the cabin maintains its lifespan.

What is freeze desalination?

Freeze desalination is an efficient method of desalting brackish water. Cold energy from ice melting is recovered for air conditioning. The hydrogen storage enables continuous operation. Agricultural activities in remote desert locations face significant challenges due to high water and energy demands and the lack of necessary infrastructure.

How are energy storage batteries integrated in a non-walk-in container?

The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron phosphate battery system, BMS system, power distribution system, firefighting system, DC bus system, thermal management system, and lighting system, among others.

How long is a 5MWh liquid-cooling energy storage cabin?

The layout project for the 5MWh liquid-cooling energy storage cabin is shown in Figure 1. The cabin length follows a non-standard 20’GP design (6684mm length × 2634mm width × 3008mm height). Inside, there are 12 battery clusters arranged back-to-back, each with an access door for equipment entry, installation, debugging, and maintenance.

Update Information

- Energy Storage Liquid Cooling 2971186Z Space

- The energy storage period of the energy storage power station is 5MWH liquid cooling

- Chile energy storage liquid cooling equipment manufacturer

- Liquid Cooling Energy Storage Container Base Station

- Jordan Liquid Cooling Energy Storage Operation

- Liquid Cooling Energy Storage Cabinet Portable

- ASEAN Energy Storage Liquid Cooling Unit

- CRRC outdoor liquid cooling energy storage cabinet

- Energy storage air cooling and liquid cooling

- Huawei energy storage liquid cooling pack

- Energy Storage Battery Container Liquid Cooling System Manufacturers Ranking

- St George Liquid Cooling Energy Storage Cabinet Manufacturer

- Norway liquid cooling energy storage service

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

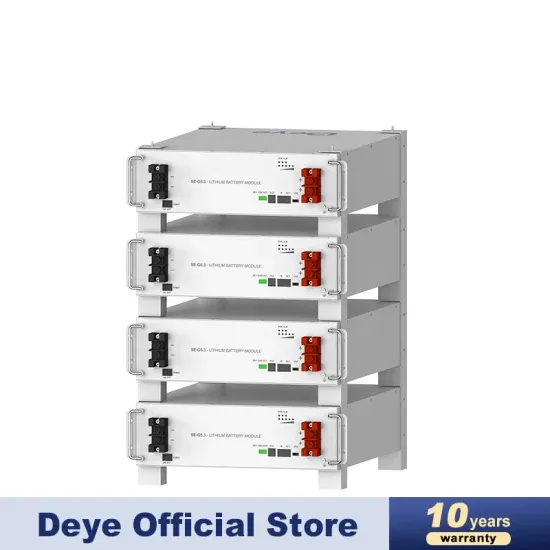

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.