Impedance estimation of photovoltaic modules for

Apr 9, 2019 · The PV panel parasitic capacitance decides the amount of leakage current to ground and therefore may impact the safety of operating professionals [3]. PV capacitance can

Impedance estimation of photovoltaic modules for

Aug 26, 2017 · The PV panel parasitic capacitance decides the amount of leakage current to ground and therefore may impact the safety of operating professionals [3]. PV capacitance can

Comprehensive overview of grid interfaced solar photovoltaic

Feb 1, 2017 · Grid-connected solar photovoltaic (PV) systems are increasingly attracting the attention of industry and academia mainly motivated by potential to provide an alternative to

Capacitance of photovoltaic panel to ground

Does parasitic capacitance affect leakage current in photovoltaic system? Abstract: The occurrence of leakage current that can occur in photovoltaic (PV) system depends strongly on

New mathematical model from system standpoint to

Jan 8, 2021 · Abstract: One of the recently arisen issues for transformerless grid-connected photovoltaic (PV) systems is high-frequency leakage current, which flows through the parasitic

Technical Information

Oct 4, 2019 · Since the leakage current is directly dependent on the capacitance of the PV module to ground, for each line voltage a capacitance limit can be specified, above which operation

Leakage Current Calculation for PV Inverter System Based on

Jan 13, 2016 · This paper presents a novel 2-D parasitic edge capacitance model and a straightforward approach to accurately calculate the involved panel parasitic capacitance. The

Effect of Semiconductor Parasitic Capacitances on

Photovoltaic plants are particularly prone to ground leakage current issues, since the PV modules exhibit a large stray capacitance CPV with respect to grounded metallic structures that are part

How to measure capacitance on photovoltaic panels

Photovoltaic(PV) cell capacitance measurement has drawn attention of researchers in recent times owing to the importance of dynamically modelling a PV panel when it interacts with

Complete parasitic capacitance model of photovoltaic panel

Aug 12, 2020 · Common mode current suppression is important to grid-connected photovoltaic (PV) systems and depends strongly on the value of the parasitic capacitance between the PV

Add capacitors to photovoltaic panels

Download scientific diagram | Parasitic capacitance model of a PV panel. from publication: High Efficiency Single-Phase Transformer-less Inverter for Photovoltaic Applications | Photovoltaic

Common-Ground Photovoltaic Inverters for Leakage

Capacitance of photovoltaic panel to ground What is PV panel parasitic capacitance? The PV panel parasitic capacitance decides the amount of leakage current to groundand therefore

A critical review of PV systems'' faults with the relevant

Dec 1, 2023 · PhotoVoltaic (PV) systems are often subjected to operational faults which negatively affect their performance. Corresponding to different types and natures, such faults

Low cost and compact six switch seven level grid tied

Mar 14, 2025 · A six switch seven-level (S2-7 L) common ground type triple boost transformerless inverter topology for grid-tied solar PV applications is presented in this paper.

(PDF) Ground currents in a photovoltaic power plant:

Arrays of photovoltaic (PV) modules, mounted on metallic structures, always create stray capacitances between active conductors and ground. Thus, leakage currents flowing in these

Improved time-domain distance protection based on fault

Aug 1, 2024 · The fault current of the photovoltaic (PV)/battery energy storage (BES) hybrid power generation system contains harmonic components, which might cause the maloperation of the

EFFECTIVE GROUNDING FOR PV PLANTS

Aug 1, 2022 · effective grounding and elaborates on different fault protection and PV plant grounding schemes. The fault current paths of different transformer configurations are

Sustaining electrification service from photovoltaic power

Sep 1, 2020 · All PV plant components are modeled using high-frequency models, in which they are such as air-termination, grounding system, surge protective devices, PV string, inverters,

Impedance estimation of photovoltaic modules for inverter

May 9, 2017 · Starting-up of photovoltaic (PV) inverters involves pre-charging of the input dc bus capacitance. Ideally, direct pre-charging of this capacitance from the PV modules is possible

Analysis of Capacitance to Ground Formulas for Different

This work calculates the stray capacitance to ground for geometries commonly found in high-voltage laboratories and facilities, including wires or rods of different lengths, spheres and

6 FAQs about [Capacitance of photovoltaic project components to ground]

Does parasitic capacitance affect leakage current in photovoltaic system?

Abstract: The occurrence of leakage current that can occur in photovoltaic (PV) system depends strongly on the value of parasitic capacitance between PV panel and the ground. However, traditional method to acquire that value is by experience estimation.

What is a capacitor in a PV device?

The capacitor represents the accumulation of charges in the PV device. The capacitance of a PV device is attributed to both junction capacitance and diffusion capacitance, both of which are voltage dependent.

Does solar cell capacitance affect electrical characterization of photovoltaic (PV) modules?

The effect of solar cell capacitance in the electrical characterization of photovoltaic (PV) modules at Standard Test Conditions (STC) is known since the 1990s.

Does rain water affect the capacitance of PV panels?

However, the proposed model is only for the PV panels under dry and clean environmental conditions. The dependence of rain water on the capacitance is simply described rather than analyzing in detail. Furthermore, the effects of water are addressed quite differently in papers.

Can a transformerless inverter cause a stray capacitance?

ABSTRACT: Considering the structure of PV systems, a stray capacitance can appear between the PV arrays and the ground. When transformerless inverters are used, this capacitance can cause leakage currents to the ground.

What is junction capacitance?

The capacitance of a PV device is attributed to both junction capacitance and diffusion capacitance, both of which are voltage dependent. Junction capacitance represents charge storage in the depletion region of the diode and is more observed at low voltages (at cell level, for c-Si: from ∼ 0 to 0.3 V).

Update Information

- Banji Photovoltaic Power Storage Project

- The development prospects of photovoltaic cell components

- London Photovoltaic Battery Energy Storage Project

- Moldova energy storage photovoltaic project installation

- Sudan Photovoltaic Power Station Energy Storage Project

- Various components in photovoltaic projects

- Uganda Photovoltaic Energy Storage Investment Project

- Sukhumi Photovoltaic Project Energy Storage

- Photovoltaic module factory cost reduction and efficiency improvement project

- European Union Photovoltaic Power Generation Cell Components

- Argentina New Energy Photovoltaic Module Project

- Mauritius Photovoltaic Energy Storage Project

- Beirut Photovoltaic Module Project

Solar Storage Container Market Growth

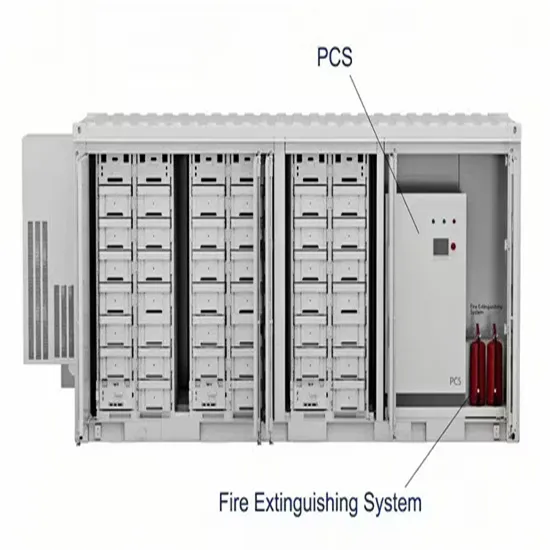

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

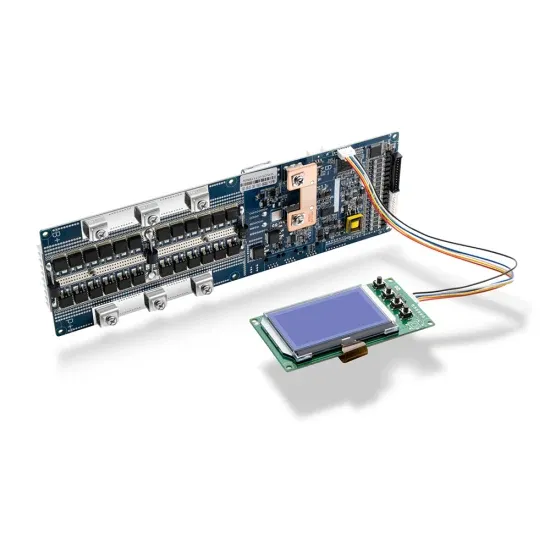

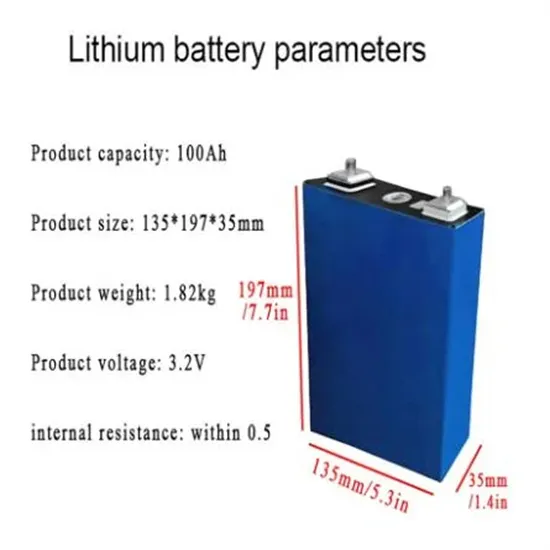

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.