How to Choose the Right Inverter for Lithium Batteries?

Apr 11, 2025 · Lithium batteries require inverters with precise voltage compatibility (e.g., 12V, 24V, or 48V systems) and stable charging profiles. Unlike lead-acid batteries, lithium variants

How to Determine What Size Inverter You Can Run Off a 100Ah Battery

Apr 21, 2025 · Determining the appropriate size of an inverter that can be run off a 100Ah battery involves understanding both the power output of the inverter and the energy capacity of the

Determining the Solar and Inverter Size Needed to Charge a Battery

Jul 29, 2025 · For a 12V 200Ah battery: 12V × 200Ah = 2400Wh. Include 20% loss: 2400Wh ÷ 0.8 = 3000Wh (required energy input) This helps refine the needed Size of your solar array.

Calculate Battery Size for Inverter Calculator

Mar 14, 2025 · The Calculate Battery Size for Inverter Calculator helps you determine the optimal battery capacity needed to support your inverter system. By inputting critical parameters such

What Size Inverter Do I Need for a 12V 100Ah Battery?

Dec 19, 2023 · When determining what size inverter you need for a 12V 100Ah battery, it''s essential to consider both your power requirements and the efficiency of your inverter system.

How to Choose the Right Inverter for Lithium Batteries?

Apr 11, 2025 · Answer: To choose the right inverter for lithium batteries, match the inverter''s voltage and capacity to your battery''s specifications, prioritize pure sine wave inverters for

How to Safely Connect a Battery to an Inverter: A

Apr 13, 2025 · Learn how to safely connect your batteries to your inverter with our guide. Avoid common wiring mistakes to optimize performance and extend

What Size Inverter for 100Ah Battery? – MWXNE POWER

May 23, 2025 · Ideal Inverter Size for a 100Ah Battery General Rule: Recommended inverter size = Battery voltage × max safe current draw For a 12V 100Ah battery, assume a max safe draw

How Big of a Battery Do I Need to Run a 2000W Inverter?

Dec 25, 2023 · To run a 2000W inverter, you typically need a battery with at least 200Ah capacity if you plan to run it for one hour. This calculation assumes a 100% efficiency rate, but in

12V vs 24V vs 48V Inverter: How to Choose the Right System

Jun 16, 2025 · Whether you''re powering an RV, building a solar setup, or running an off-grid home, choosing the right inverter system voltage is crucial. Many beginners ask: Should I use

What Size Inverter Do I Need for a 200AH Battery?

Dec 15, 2023 · To determine the appropriate inverter size for a 200AH battery, you need to consider the total wattage of the devices you plan to power. A general rule is to choose an

What Inverter Size is Best for a 100Ah Battery?

Understanding the Basics What is an Inverter? An inverter converts DC (Direct Current) power from your battery into AC (Alternating Current) power, which is used by most household

Can an Inverter Be Too Big for Your Battery System?

For a 12V 200Ah battery (2.4kWh), a 2000W inverter is ideal. Formula: Inverter Wattage ≤ (Battery Voltage × Ah Rating × 0.8). Factor in surge power needs but prioritize sustained

What size inverter can I run off a 100Ah lithium battery?

Jun 7, 2025 · A 100Ah lithium battery can typically support an inverter up to 1,200W for 1 hour, assuming a 12V system. Actual runtime depends on load wattage and battery voltage. For

Solar Inverter & Battery Sizing Calculator

Apr 30, 2025 · Choosing the correct inverter and battery size is crucial for every microgrid system. Our Solar Inverter and Battery Sizing Calculator provides a

6 FAQs about [How big an inverter should I use for a 12v 50A lithium battery]

What voltage should a 12V inverter run on?

The input voltage of the inverter should match the battery voltage. (For example 12v battery for 12v inverter, 24v battery for 24v inverter and 48v battery for 48v inverter Summary What Will An Inverter Run & For How Long?

What is the recommended battery size for an inverter?

Interpreting Results: Once you input the required data, the calculator will generate the recommended battery size in ampere-hours (Ah). For instance, if your power consumption is 500 watts, the usage time is 4 hours, and the inverter efficiency is 90%, the calculator might suggest a battery size of approximately 222 Ah.

What size inverter do I Need?

Choose an inverter Size rated for both. Inverters are available in 12V, 24V, and 48V models. Your inverter’s Size must match your battery bank voltage. Mismatched voltages can cause failure or inefficient charging. Some inverters have built-in chargers with a max current limit.

How do you size a solar inverter?

Tools and Formulas to Help You Size Your Solar and Inverter Setup Battery Wh = V × Ah Panel Size (W) = Battery Wh ÷ Sun hours ÷ Efficiency factor Inverter Size (W) = Total Continuous Load + Surge Load Buffer Several websites offer solar sizing calculators. Just input battery capacity, sun hours, and load requirements.

Does a 24V inverter need a 12V battery?

An inverter’s battery capacity must match its voltage rating. If an inverter operates at 24V, the battery bank should be designed accordingly. For instance, using two 12V batteries in series provides 24V, while a 48V system requires four 12V batteries. Ensuring proper voltage alignment prevents system overloads and ensures stable performance.

What is the calculate battery size for inverter calculator?

The Calculate Battery Size for Inverter Calculator helps you determine the optimal battery capacity needed to support your inverter system. By inputting critical parameters such as power consumption, inverter efficiency, and desired usage time, this calculator provides a precise battery size recommendation tailored to your specific needs.

Update Information

- How big a battery should a 12v inverter battery be

- How big an inverter should I use for a 12v180a battery

- How big a lithium battery should I use with a 10 watt solar panel

- How big an inverter should I use for a 24a battery

- How big a battery should a 5800w inverter use

- How big a battery should I use for a 3000w inverter

- How big a battery should I use for 5 kilowatts of solar energy

- How big an inverter can I use for 60v45ah

- How many amperes does lithium battery energy storage generally use

- What size inverter should I use for a 150a lithium battery

- Inverter 12v lithium iron phosphate battery assembly

- How big an inverter should I use for 3OoV solar panels

- How big a battery should a 12V 50 watt solar panel be equipped with

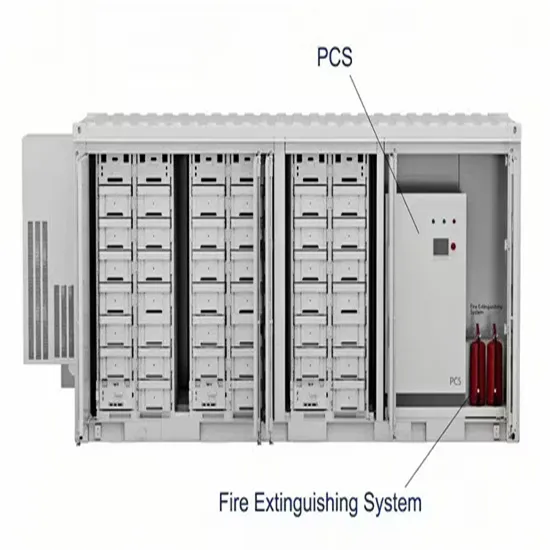

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.