New fuel cell could help fix the renewable energy storage problem

Mar 12, 2019 · When both teams run their setups in reverse, the fuel electrode splits H 2 molecules into protons and electrons. The electrons travel through an external wire to the air

Fuel cell as an effective energy storage in reverse

Mar 27, 2019 · Abstract─ A hybrid renewable energy systems (HRESs) comprises of photovoltaic (PV), and self-charging fuel cells (SCFC) is designed for securing electrical energy required to

IEC 62282-8-101

Feb 1, 2020 · Fuel cell technologies – Part 8-101: Energy storage systems using fuel cell modules in reverse mode – Test procedures for the performance of solid oxide single cells and stacks,

Fuel cell as an effective energy storage in reverse osmosis

Feb 1, 2019 · This study opens the way for using a fuel cell as an effective method for solving the energy intermittence/storage problems of renewable energy sources.

IEC/TS 62282-8-102 Energy storage systems using fuel cell

Aug 18, 2025 · This part of IEC 62282-8-102 provides for PEM cell/stack assembly unit, testing systems, instruments and measuring methods, and test methods to test the performance of

Reversible fuel cells

Jan 1, 2016 · Reversible fuel cells (RFCs) offer a solution to producing fuel through the use of surplus electricity and reconverting this into electricity using the same device. In autonomous

Reverse mode fuel cells for energy storage

May 25, 2017 · Although it requires the hydrogen handling infrastructure to be set up, the use of fuel cell systems in reversing mode for alternating power storage and power generation within

Techno-economic analysis of energy storage systems using

May 15, 2022 · The adoption of batteries and fuel cells as energy storage systems is growing substantially in the commercial and power generation sectors, helping increase the resiliency

The role of fuel cells in energy storage

Mar 1, 2000 · A fuel cell-based energy storage system allows separation of power conversion and energy storage functions enabling each function to be individually optimized for performance,

DOE Announces $4 Million to Advance Reversible Solid Oxide Fuel Cell

Oct 4, 2024 · The U.S. Department of Energy''s (DOE''s) Office of Fossil Energy and Carbon Management recently announced up to $4 million in federal funding to advance clean

Progress and prospects of reversible solid oxide fuel cell

Dec 17, 2021 · Summary Reversible solid oxide fuel cell (RSOFC) is an energy device that flexibly interchanges between electrical and chemical energy according to people''s life and production

What Are Regenerative Fuel Cells?

Mar 12, 2021 · In fact many fuel cells are designed to prevent the reverse reaction from occurring at all, for why would you want to consume the energy you just produced? Instead you might

Regenerative Fuel Cells for Energy Storage

Apr 29, 2014 · Regenerative or reversible fuel cells (RFCs) are capable of both power generation and, in a reverse mode, production of a fuel. This paper focuses on the use of hydrogen-based

Modeling, optimization, and economic analysis of a

Nov 1, 2023 · Modeling, optimization, and economic analysis of a comprehensive CCHP system with fuel cells, reverse osmosis, batteries, and hydrogen storage subsystems Powered by

Techno-economic analysis of energy storage systems using

May 15, 2022 · Fuel cells are designed to operate continuously, mainly reversible solid oxide cells and, to a lesser extent, the PEM fuel cells in the load following mode (i.e., the storage duration

IEC/TS 62282-8-201 Energy storage systems using fuel cell

Apr 19, 2025 · This part of IEC 62282 defines the evaluation methods of typical performances for electric energy storage systems using hydrogen. This is applicable to the systems which use

Fuel cell as an effective energy storage in reverse osmosis

A hybrid renewable energy systems (HRESs) comprises of photovoltaic (PV), and self-charging fuel cells (SCFC) is designed for securing electrical energy required to operate brackish water

Modeling, optimization, and economic analysis of a

Jan 1, 2024 · Modeling, optimization, and economic analysis of a comprehensive CCHP system with fuel cells, reverse osmosis, batteries, and hydrogen storage subsystems Powered by

Fuel cell as an effective energy storage in reverse

Mar 11, 2021 · Abstract─A hybrid renewable energy systems (HRESs) comprises of photovoltaic (PV), and self-charging fuel cells (SCFC) is designed for securing electrical energy required to

New fuel cell material can run efficiently in

Mar 14, 2019 · Operating in reverse, they''ll use electricity to drive the production of hydrogen starting with water, or methane if given water and CO 2. This

Fuel cell as an effective energy storage in reverse osmosis

A hybrid renewable energy systems (HRESs) comprises of photovoltaic (PV), and self-charging fuel cells (SCFC) is designed for securing electrical energy required to operate brackish water

New fuel cell could help fix the renewable energy storage problem

Mar 12, 2019 · Devices called electrolyzers do this by using electricity—ideally from solar and wind power—to split water into oxygen and hydrogen gas, a carbon-free fuel. A second set of

Reversible Solid Oxide Fuel Cell Systems for Energy Storage

May 27, 2022 · FuelCell Energy (FCE) studied the performance, design, and economics of a reversible solid-oxide fuel cell/electrolyzer integrated with a natural gas-based electricity

IEC 62282-8-102

Dec 1, 2019 · Fuel cell technologies – Part 8-102: Energy storage systems using fuel cell modules in reverse mode – Test procedures for the performance of single cells and stacks with proton

Reversible Fuel Cell Cost Analysis

Apr 30, 2020 · The extent to which hydrogen energy storage costs can be reduced by consolidating electrolyzers and fuel cell stacks in a unitized, reversible fuel cell. Hydrogen

6 FAQs about [Fuel cell reverse energy storage]

What are reversible solid oxide fuel cells (rsofcs)?

There has been particular interest in reversible solid oxide fuel cells (RSOFCs) in the energy sector for electricity, energy storage, grid stabilization and improvement to power plant system efficiency due to favorable thermodynamic efficiencies of high temperature steam electrolysis.

What is a reversible fuel cell?

One option for cutting the costs is what's called a reversible fuel cell. Fuel cells simply separate different parts of a chemical reaction so that the electrons that are transferred during the reaction can be used as a source of electricity.

What is a reversible SOFC energy storage system?

Reversible SOFC energy storage system demonstrated at Boeing Huntington Beach connected to the Southern California Edison grid. The fuel cell system (Figure 6), located inside the enclosed shipping container, consists of two solid oxide cell modules, a gas and air supply unit, exhaust gas treatment unit, steam generator, and DAQ cabinet.

Can solid oxide fuel cell stack be reversible?

Operation of solid oxide fuel cell stack in reversible mode for hydrogen generation for molten carbonate fuel cell as power-to-gas process

What is a TMI reversible fuel cell?

However, compared to other fuel cells that operate at low temperature (e.g., proton exchange membrane (PEM)), the TMI reversible system can use the waste thermal energy produced during electricity generation mode to achieve high systems efficiency in electrolyzer mode, ultimately lowering product life cycle costs for the combined system.

Can a fuel cell stack reduce energy storage cost?

That is, combining the electrolyzer and the fuel cell functions in a unitized stack can help reduce the initial system cost, but the expected low round-trip efficiency usually outweighs this advantage, thus lowering the levelized cost of energy storage may not be easily achieved .

Update Information

- Is the fuel cell electric an energy storage device

- Energy Storage High Temperature Fuel Cell

- Vilnius Heneng Energy Storage Fuel Cell

- Photovoltaic energy storage fuel cell

- Is the energy storage cabinet battery a solar cell

- Bahrain communication base station solar cell energy storage cabinet

- Solar cell energy storage dedicated 12v100ah

- Ulaanbaatar energy storage reverse power protection device

- How many kw does a standard cell of energy storage battery have

- Jamaica energy storage lithium battery cell

- Tallinn Energy Storage Cell Project

- Off-grid energy storage reverse control charging pile

- Solar cell capacitor energy storage

Solar Storage Container Market Growth

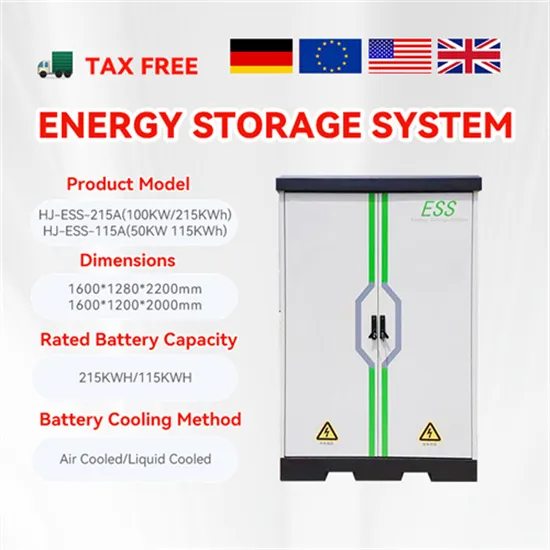

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

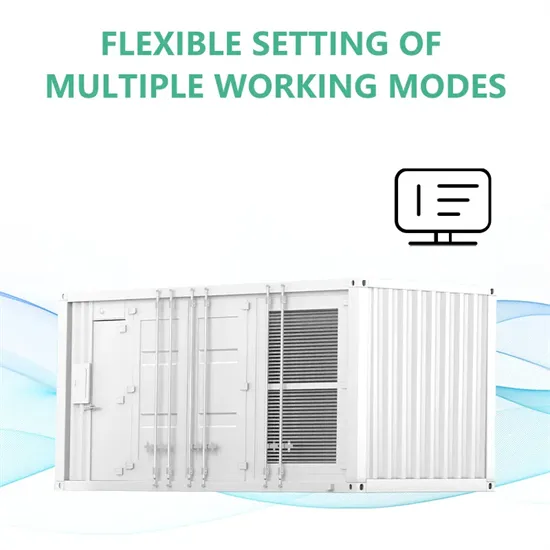

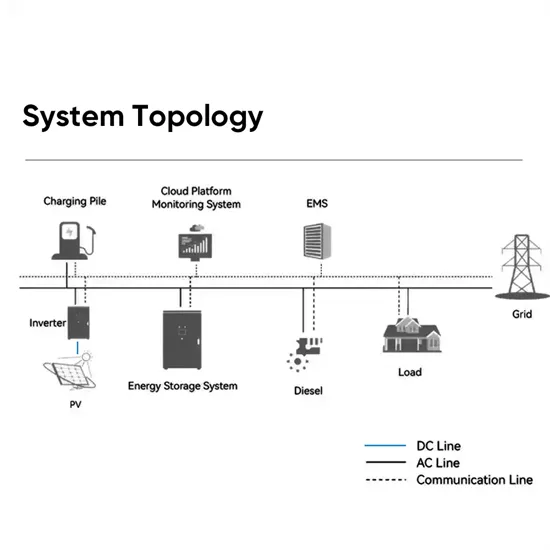

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.