Long-Term Value Of Scenario-Optimized Energy

May 14, 2025 · The energy storage container of a coastal factory adopts a dual cycle liquid cooling system to control the temperature fluctuation of the battery

How do energy storage containers address the challenges of

Apr 23, 2025 · Load Leveling and Peak Shaving: Modular containers enable efficient energy storage from intermittent renewable sources by ensuring that surplus energy generated during

Energy Storage Containers for Factories: Powering the Future

The $33 Billion Game You Didn''t Know You Were Playing Right now, the global energy storage market is rocking a $33 billion valuation—and factories are claiming their slice of the pie [1].

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

The Nuts and Bolts of Energy Storage Company Factory Operation

The 3-Legged Stool of Factory Operations [8] Recent data from China''s Qinghai province shows smart factories achieving 92% OEE (Overall Equipment Effectiveness) – here''s how:

Energy storage containers: an innovative tool in the green

Mar 13, 2024 · This article introduces the structural design and system composition of energy storage containers, focusing on its application advantages in the energy field. As a flexible and

Eaton xStorage Container Containerized energy storage

Sep 4, 2024 · All-in-one container Eaton xStorage is now available in a containerized version. This all-in-one, ready-to-use solution is the perfect choice for energy storage applications in

A framework for the design of battery energy storage

Jul 1, 2025 · We introduce a criterion minimizing the size of battery energy storage systems. A flexible supply schedule is drawn to manage erratic renewable electricity inputs. Full

20HC Smart ESS Container Solar Energy Storage System

Energy storage systems are applied in various scenarios, mainly focused on the power system. They can meet peak electricity demand, provide high-power switching in a short period of time,

How to Successfully Run a New Energy Storage Cabinet Factory Operation

With global demand for battery storage projected to hit $546 billion by 2035 (BloombergNEF), launching a new energy storage cabinet factory operation isn''t just smart – it''s like catching

BATTERY ENERGY STORAGE SYSTEMS

Nov 9, 2022 · Sinovoltaics advice: we suggest having the logistics company come inspect your Battery Energy Storage System at the end of manufacturing, in order for them to get

Designing a BESS Container: A Comprehensive Guide to Battery Energy

Apr 10, 2023 · The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

The Future of Energy Storage: Inside Modern Manufacturing Production

Ever wonder how those sleek energy storage containers powering solar farms and wind turbines come to life? Let''s pull back the curtain on the manufacturing production line that''s

Kuwait City Energy Storage Container Factory Operation

Container High Safety: Efficient and reliable liquid cooling system, using up-to-date LFP battery, equipped with multiple intelligent fire extinguishing system to ensure safe operation High

Key Design Considerations for Energy Storage Containers

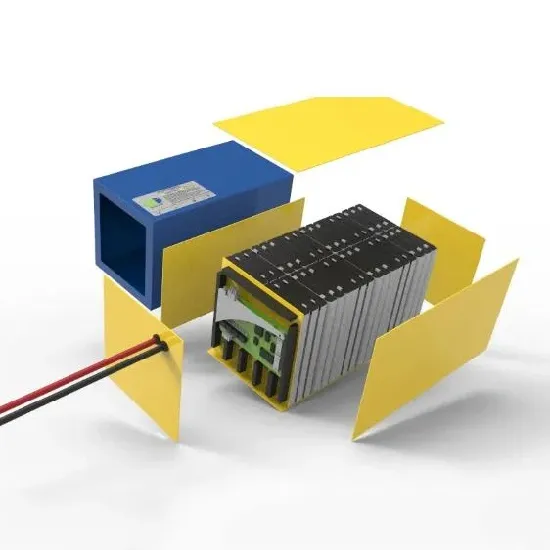

Apr 11, 2025 · Design considerations should include battery capacity, voltage range, and cycle life, with a focus on maximizing energy storage efficiency and system longevity. Effective

A framework for the design of battery energy storage

Jul 1, 2025 · Energy storage has become increasingly crucial as more industrial processes rely on renewable power inputs to achieve decarbonization targets and meet stringent environmental

6 FAQs about [Energy storage container production design factory operation]

How do I design a battery energy storage system (BESS) container?

Designing a Battery Energy Storage System (BESS) container in a professional way requires attention to detail, thorough planning, and adherence to industry best practices. Here's a step-by-step guide to help you design a BESS container: 1. Define the project requirements: Start by outlining the project's scope, budget, and timeline.

When does an energy storage project start?

“The operations and maintenance phase of an en- ergy storage project begins when the system has been successfully commissioned and the owner has obtained approval to operate the system.

Do battery energy storage systems look like containers?

C. Container transportation Even though Battery Energy Storage Systems look like containers, they might not be shipped as is, as the logistics company procedures are constraining and heavily standardized. BESS from selection to commissioning: best practices38 Firstly, ensure that your Battery Energy Storage System dimensionsare standard.

How are battery energy storage systems transported?

Given the Battery Energy Storage System’s dimen- sions, BESS are usually transported by sea to their destination country (if trucking is not an option), and then by truck to their destination site. A.Logistics The consequence is that the shipment process can be worrisome.

What is a storage system?

In this regard, storage systems may refer to mass or energy accumulation. In the case of mass, storage systems typically consist of tanks and vessels providing/accumulating raw materials or (intermediate) products. In the case of energy, the nature of the storage system strictly depends on the form of energy.

Does container manufacturing take a lot of space?

Container manufacturing can take (a lot of) space. If your project requires a 40ft container, your contain- er manufacturing will probably take place outdoors. During that step, several points need to be looked at: • Manufacturing environment: no clean room re- quired here, but is there any risk of electrocution following a heavy rain?

Update Information

- Managua battery energy storage container factory is in operation

- Iran energy storage container production factory

- Marshall Islands container energy storage system factory operation

- Design of energy storage container for photovoltaic power station

- Battery container energy storage design

- Energy storage container processing production line site

- North Asia container energy storage cabinet factory price

- Energy storage container design specifications and requirements

- Roman energy storage container production

- West African Energy Storage Container Production

- Turkmenistan energy storage container house design

- Factory inspection of container energy storage system

- Lebanon energy storage container sales factory is running

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.