Integrated Design of Large-Scale Energy Storage Systems,

Aug 9, 2025 · Integrated Design of Large-Scale Energy Storage Systems, with Equipment Such as Battery Clusters and Battery Combiner Cabinets Integrated Into Containers, Find Details

Tne Energy Storage System Inspection Energy Storage

Aug 11, 2025 · At Tedian Energy (TNE), we go beyond delivering cutting-edge energy storage solutions. To ensure complete confidence in our products and processes, we offer Third-Party

Energy Storage System Safety: Plan Review and

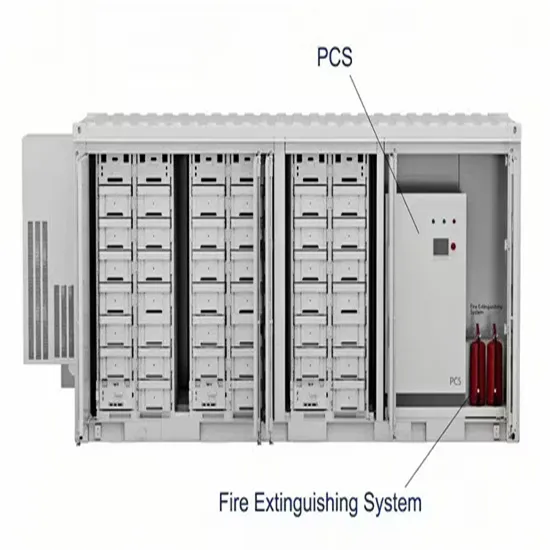

Apr 4, 2017 · Self-contained, prepackaged, or pre-engineered energy storage systems that include fire and smoke detection systems in accordance with the manufacturer''s installation

From Design to Delivery: Six Key Capabilities Every Battery Container

May 16, 2025 · As global deployment of energy storage systems accelerates, the battery container has evolved far beyond a basic structural enclosure. It now plays a pivotal role in

Container Energy Storage Factory Test Report: Why Your

Think of factory testing as first dates for energy storage systems. You want to discover the crazy before signing a marriage certificate with that battery container. Because let''s face it – divorce

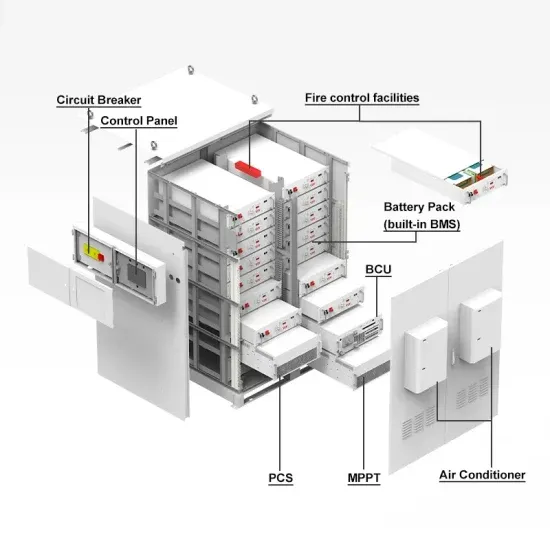

Original Factory AC 400V Liquid-Cooling (C & I) Energy Storage Container

Jul 18, 2025 · Product Description Product Description This product uses an integrated energy storage cabinetas the carrier for the energy storage system.Featuringa modular design, it

Battery Energy Storage储能电池及系统 System

Jun 12, 2023 · Energy储能系统(ESS) Storage System In recent years, the trend of combining electrochemical energy storage with new energy develops rapidly and it is common to move

Container energy storage system inspection

By adopting a shipping container energy storage system, you are not just investing in a piece of technology; you are endorsing a sustainable future.Whether for personal use, community

BATTERY FAT and SAT Major Testing Components

Jun 22, 2024 · Factory Acceptance Testing is a critical step in ensuring the quality, safety, and reliability of energy storage battery systems. By conducting thorough and comprehensive FAT,

Energy storage battery container factory inspection

What are the two phases of energy storage battery testing? When it comes to ensuring the quality,performance,and reliability of energy storage battery systems,two critical phases stand

DS 5-33 Lithium-Ion Battery Energy Storage Systems

Sep 30, 2023 · 1.0 SCOPE This data sheet describes loss prevention recommendations for the design, operation, protection, inspection, maintenance, and testing of stationary lithium-ion

DS 5-33 Lithium-Ion Battery Energy Storage Systems

Mar 10, 2024 · 1.0 SCOPE This data sheet describes loss prevention recommendations for the design, operation, protection, inspection, maintenance, and testing of stationary lithium-ion

Experience Unmatched Energy Efficiency With Container Energy Storage

Introducing the Container Energy Storage System (CESS), the most compact and powerful energy storage system on the market. Our modular system comes in 20ft and 40ft containers

Battery Energy Storage System Inspection and Testing

Mar 13, 2023 · SCOPE These Checklists provide information on the Inspection and Testing activities to be carried out by the Applicant contractor at the end of the construction of a BESS,

集装箱储能综合测试平台BESS-FAT(Battery Energy

Dec 27, 2023 · 锂电储能系统综合检测平台BESS-FAT的研发,旨在打造成为储能行业保障产品质量、提升制造效率、确保服役安全的一个重要工具。 未来,

BESS Factory Acceptance Testing Procurement Checklist

Conclusion Factory Acceptance Testing (FAT) is an essential step in BESS quality assurance, ensuring that the system meets technical, performance, and safety standards before

Container Energy Storage System 1C 344-250KW/344kWh

Introducing the Container Energy Storage System (CESS), the most compact and powerful energy storage system on the market. Our modular system comes in 10ft container and is

6 FAQs about [Factory inspection of container energy storage system]

Do battery energy storage systems look like containers?

C. Container transportation Even though Battery Energy Storage Systems look like containers, they might not be shipped as is, as the logistics company procedures are constraining and heavily standardized. BESS from selection to commissioning: best practices38 Firstly, ensure that your Battery Energy Storage System dimensionsare standard.

When should a battery energy storage system be inspected?

Sinovoltaics advice: we suggest having the logistics company come inspect your Battery Energy Storage System at the end of manufacturing, in order for them to get accustomed to the BESS design and anticipate potential roadblocks that could delay the shipping procedure of the Energy Storage System.

When does an energy storage project start?

“The operations and maintenance phase of an en- ergy storage project begins when the system has been successfully commissioned and the owner has obtained approval to operate the system.

What should be included in a contract for an energy storage system?

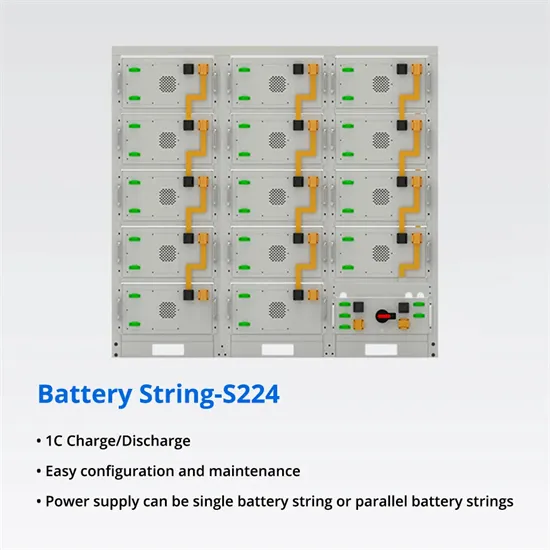

Several points to include when building the contract of an Energy Storage System: • Description of components with critical tech- nical parameters:power output of the PCS, ca- pacity of the battery etc. • Quality standards:list the standards followed by the PCS, by the Battery pack, the battery cell di- rectly in the contract.

How are battery energy storage systems transported?

Given the Battery Energy Storage System’s dimen- sions, BESS are usually transported by sea to their destination country (if trucking is not an option), and then by truck to their destination site. A.Logistics The consequence is that the shipment process can be worrisome.

What is a battery energy storage system (BESS) e-book?

This document e-book aims to give an overview of the full process to specify, select, manufacture, test, ship and install a Battery Energy Storage System (BESS). The content listed in this document comes from Sinovoltaics’ own BESS project experience and industry best practices.

Update Information

- Nassau Energy Storage Container Distribution Box Factory

- Marshall Islands container energy storage system factory operation

- Energy storage container solar photovoltaic module factory photothermal equipment

- How big is the energy storage container factory

- Iran energy storage container production factory

- What material is the energy storage container factory made of

- China-Africa Energy Storage Container Factory

- Luxembourg container energy storage cabinet factory price

- Israel Energy Storage Container Customization Factory

- Energy storage container inspection process

- Netherlands Energy Storage Container Customization Factory

- Chad Energy Storage Container Manufacturing Factory

- Guyana Energy Storage Container Customization Factory

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.