A comparison of battery-charger topologies for portable

Apr 2, 2019 · The pack configuration directly imposes specific charger requirements, such as charging voltage and current. In addition to these factors, inside a battery-powered device, a

Lithium Storage Base Station Batteries | We Group E-Site

The Coming Solid-State Revolution While current Li-ion solutions dominate, quantumscape-style solid-state prototypes already show 500+ Wh/kg density in lab environments. Imagine base

Lithium Battery Charging Stations for Electric Vehicles

Jul 24, 2023 · Dive into the realm of lithium battery charging stations, exploring their features, benefits, applications, and considerations for choosing the right one.

Lithium-ion battery degradation caused by overcharging at low

May 1, 2022 · Batteries can experience overcharging due to inconsistencies of the battery properties or failure of the battery management system which accelerates battery degradation.

Experimental study on self-heating strategy of lithium-ion battery

Jan 15, 2024 · Preheating is an effective solution to the severe degradation of lithium-ion battery (LIB) performance at low temperatures. In this study, a bidirectional pulse-current preheating

Temperature-aware charging strategy for lithium-ion batteries

Dec 15, 2023 · To address these deficiencies, this paper designs a novel charging strategy that optimizes the charging of lithium-ion batteries at low temperatures with adaptive current

A Fast Charging Method for Lithium-ion Batteries Considering Charging

Dec 3, 2024 · Fast charging of lithium-ion batteries (LIBs) is a key technology for the popularization of electric vehicles. However, regardless of physical constraints, high-rate

The design of fast charging strategy for lithium-ion batteries

Jan 1, 2025 · The article initially examines various common charging strategies, followed by an in-depth exploration of the effects of multi-level fast charging strategies on battery life, charging

Challenges and recent progress in fast-charging lithium-ion battery

Jun 30, 2023 · The electrode materials are most critical for fast charging, which performances under high-rate condition greatly affect the fast-charging capability of the batteries. This review

Innovative method to precise SOC estimation for lithium-ion batteries

Dec 27, 2024 · Lithium-ion (Li-ion) batteries have become the preferred choice for a wide range of applications, from consumer electronics to electric vehicles (EVs), due to their high energy

Research on pulse charging current of lithium-ion batteries

Sep 1, 2023 · Particularly, fast charging at low temperatures can cause lithium to deposit on the anode of the battery, intensifying heat production and even evolving into thermal runaway of

A Self-Heating and Charging Coordinated Strategy for Low

Feb 1, 2024 · Experimental results demonstrate that the proposed strategy can charge LiBs to 80% SOC in 1.55 h at −10 °C, which is 6.65× faster than the conventional little-current

Review of fast charging strategies for lithium-ion battery

Dec 15, 2021 · Many different approaches have been taken to develop new fast charging strategies for battery management systems to solve the dilemma between charging speed and

BU-410: Charging at High and Low Temperatures

Mar 1, 2022 · Li-ion batteries charging below 0°C (32°F) must undergo regulatory issue to certify that no lithium plating will occur. In addition, a specially designed charger will keep the allotted

Lithium Storage Base Station Insights: Powering the Future

The Solid-State Horizon: What 2025 Holds With solid-state lithium batteries achieving 500 Wh/kg in lab conditions (Samsung SDI, Q2 2024), base stations could potentially halve their physical

The next generation of fast charging methods for Lithium-ion batteries

Jul 1, 2022 · The fast charging of Lithium-Ion Batteries (LIBs) is an active ongoing area of research over three decades in industry and academics. The objective is

Optimal charge current of lithium ion battery

Dec 1, 2017 · The aim of this research is to provide an optimal charge current of lithium ion battery, by which the theoretically fastest charging speed without lithium deposition is able to

Challenges and opportunities toward fast-charging of lithium-ion batteries

Dec 1, 2020 · The high-rate charging, however, leads to lithium inventory loss, mechanical effects and even thermal runaway. Therefore, the optimal charging algorithm of Li-ion batteries should

Research on charging strategy of lithium-ion battery system at low

A charging strategy at a low temperature for lithium battery systems is proposed and improved based on the principle that the battery generates heat by itself during charging.

Battery Charging

Apr 1, 2023 · The complexity (and cost) of the charging system is primarily dependent on the type of battery and the recharge time. This chapter will present charging methods, end-of-charge

Design and optimization of lithium-ion battery as an efficient

Nov 1, 2023 · The applications of lithium-ion batteries (LIBs) have been widespread including electric vehicles (EVs) and hybridelectric vehicles (HEVs) because of their lucrative

International Space Station Lithium-Ion Battery

Mar 21, 2024 · International Space Station Lithium-Ion Battery NASA Aerospace Battery Workshop November 15, 2016 Penni J. Dalton, NASA Glenn Research Center Eugene

Investigating effects of pulse charging on performance of Li

Aug 1, 2023 · The model results show that pulse charging enhances uniformity of lithium-ion distribution in the battery, thereby improving the battery performance. This research

A state of health estimation method for lithium-ion batteries

May 15, 2025 · A state of health estimation method for lithium-ion batteries based on initial charging segment and Gated Recurrent Unit neural network

The Basics of Charging Lithium Batteries | RELiON

Aug 26, 2024 · Whether you''re using lithium batteries as part of a portable power station, or to power your boat, golf car or RV, understanding the basics of

Charging Lithium Ion Batteries: A

Jan 19, 2024 · 1. Pre-charging stage In this state, first detect whether the single lithium-ion battery voltage is low (<3.0V), if so, trickle charging is used, that is,

A novel framework for low-temperature fast charging of lithium

Oct 1, 2024 · Charging the battery SOC from 0.2 to 0.9 in 42 min at −10 °C, without triggering lithium plating, is feasible with this proposed strategy. Compared to strategies focusing solely

6 FAQs about [Base station lithium battery low current charging]

Can low-temperature lithium-ion batteries be charged fast?

Aiming at the issues of low available capacity and difficult charging of lithium-ion batteries (LIBs) at low-temperature, existing low-temperature charging methods are difficult to achieve fast charging due to the splitting of the fast preheating and charging processes. Therefore, an integrated heating–charging method is proposed.

What are the different lithium-ion battery non-feedback-based charging strategies?

In general, the available lithium-ion battery non-feedback-based charging strategies can be divided into four model-free methodology classes, including traditional, fast, optimized, and electrochemical-parameter-based (EP-based) charging approaches as shown in Figure 3 [36 - 40].

Can lithium-ion batteries be fast charged without lithium plating?

A novel electro-thermal coupled model is proposed. A three-electrode battery is constructed for study. A low-temperature charging framework is developed. This paper proposes a novel framework for low-temperature fast charging of lithium-ion batteries (LIBs) without lithium plating.

Can a Li-ion battery be charged below 0°C (32°F)?

Li-ion batteries charging below 0°C (32°F) must undergo regulatory issue to certify that no lithium plating will occur. In addition, a specially designed charger will keep the allotted current and voltage within a safe limit throughout the temperature bandwidth.

Can a lithium ion battery be charged below 0°C?

Many battery users are unaware that consumer-grade lithium-ion batteries cannot be charged below 0°C (32°F). Although the pack appears to be charging normally, plating of metallic lithium occurs on the anode during a sub-freezing charge that leads to a permanent degradation in performance and safety.

Is a low-temperature battery charging strategy reliable and feasible?

These observations collectively suggest that the low-temperature charging strategy proposed in this study is reliable and feasible. Another important validation concerns the absence of lithium plating. Fig. 10 (H) illustrates the results for the graphite negative potential of the three-electrode battery.

Update Information

- Calculation formula for the battery life of a communication base station lithium battery

- Lithium battery station cabinet customized base station power generation

- Albania lithium battery energy storage cabinet price base station

- Communication base station lithium ion battery room foundation

- Battery current of communication base station

- Communication base station lithium iron battery supplier

- Base station lithium iron phosphate battery communication base station

- Large square lithium battery station cabinet base station energy

- Current price of communication base station battery module

- Wellington Communication Base Station Lithium Ion Battery Application

- Lithium battery station cabinet charging cabinet

- Base station intelligent lithium battery

- Communication base station battery rru classification

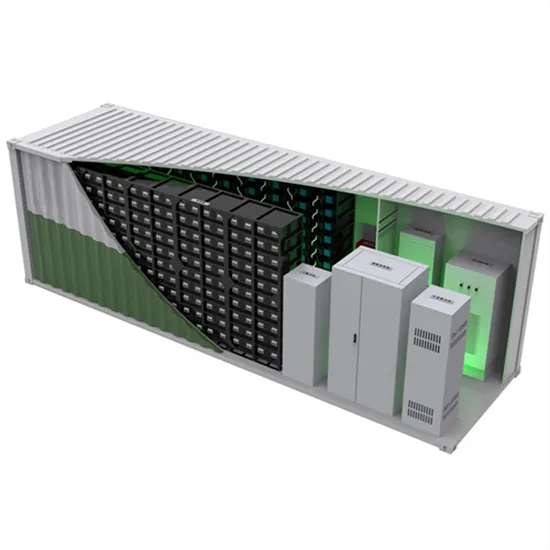

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

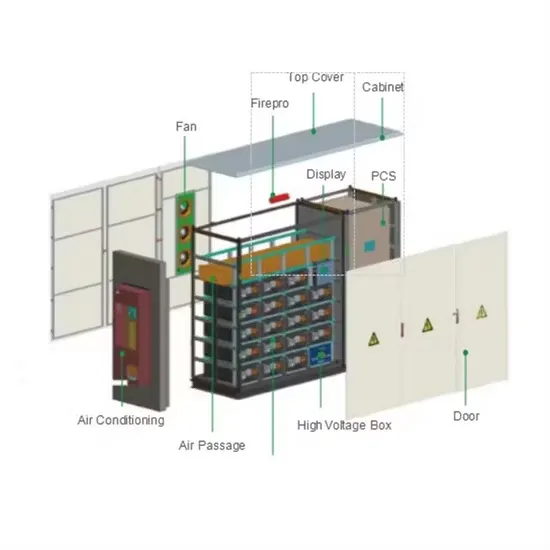

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.