Global Communication Base Station Li-ion Battery Market

The Communication Base Station Li-ion Battery market is essential for powering the backbone of telecommunication infrastructure, enabling reliable connectivity in today''s fast-paced digital

Use of Batteries in the Telecommunications Industry

Mar 18, 2025 · The few telecom battery fires have been related to installation mistakes Lithium-Ion Electrolyte can be highly flammable Electronic controllers – potentially prone to failure are

18650 lithium battery supporting application in 5G base stations

18650 lithium battery supporting application in 5G base stations, light vehicles, power tools, and shipbuilding industries Accompanying the electrification of automobiles is the comprehensive

Lifepo4 Battery Pack Will Be the Main Application of Communication.

Oct 13, 2020 · In the 5G era, the trend of base station miniaturization and integration has put forward higher requirements for lithium battery backup power supply performance. LiFePO4

What is the purpose of batteries at telecom base

Feb 10, 2025 · The lead storage battery is the most widely used energy storage battery in the current communication power supply. Among the many types of

【MANLY Battery】Lithium batteries for communication base stations

Mar 6, 2021 · In the future, especially after the 5G upgrade, lithium battery companies will no longer simply focus on communication base stations, but on how the communication network

Lithium battery for communication base station

Through exploiting the correlations between the battery working conditions and battery statuses, we build up a deep learning based model to estimate the remaining lifetime of backup

Lithium-ion Battery For Communication Energy Storage System

Aug 11, 2023 · It is expected that the next few years will be the peak of 5G base station construction, and by 2025, the battery demand for new and renovated 5G base stations in

2023-2029全球及中国通信基站锂电池行业研究及十四五规划

2023-2029全球及中国通信基站锂电池行业研究及十四五规划分析报告 2023-2029 Global and China Communication Base Station Li-ion Battery Industry Research and 14th Five Year Plan

Battery for Communication Base Stations Market

The Battery for Communication Base Stations market can be segmented by battery type, including lithium-ion, lead acid, nickel cadmium, and others. Among these, lithium-ion batteries

Communication Base Station Li-ion Battery Market''s

Mar 30, 2025 · The global Communication Base Station Li-ion Battery market is experiencing robust growth, driven by the increasing deployment of 5G and other advanced wireless

Lithium Battery Base Station: Revolutionizing Telecom

The recent breakthrough in sulfide-based solid-state batteries (Toyota, Jan 2024) promises to revolutionize base station energy storage. When implemented at scale, these innovations

Environmental feasibility of secondary use of electric vehicle lithium

May 1, 2020 · Abstract Repurposing spent batteries in communication base stations (CBSs) is a promising option to dispose massive spent lithium-ion batteries (LIBs) from electric vehicles

Lithium iron phosphate battery for communication base stations

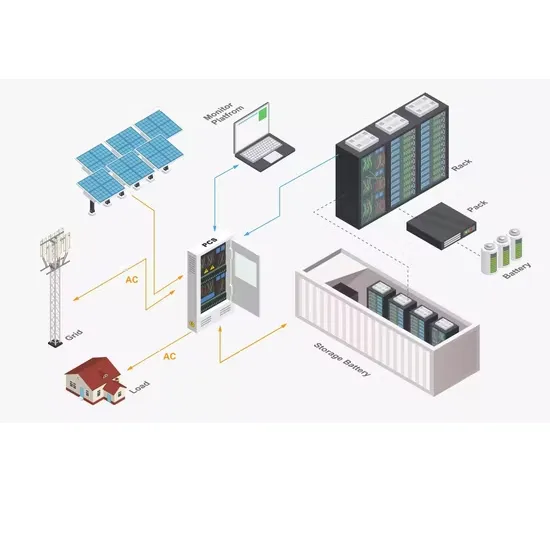

Our range of products is designed to meet the diverse needs of base station energy storage. From high-capacity lithium-ion batteries to advanced energy management systems, each

Environmental-economic analysis of the secondary use of

Nov 30, 2022 · This study examines the environmental and economic feasibility of using repurposed spent electric vehicle (EV) lithium-ion batteries (LIBs) in the ESS of

【MANLY Battery】Lithium batteries for communication base stations

Mar 6, 2021 · In general, as the demand for 5G communication base stations continues to increase, there will be considerable market space for lithium battery energy storage in the

Communication Base Station Energy Storage Lithium Battery

Apr 6, 2025 · The Communication Base Station Energy Storage Lithium Battery market is experiencing robust growth, driven by the increasing demand for reliable and efficient power

Base station energy storage lithium battery

Jul 21, 2024 · 2) The optimized configuration results of the three types of energy storage batteries showed that since the current tiered-use of lithium batteries for communication base station

6 FAQs about [Communication base station lithium ion battery room foundation]

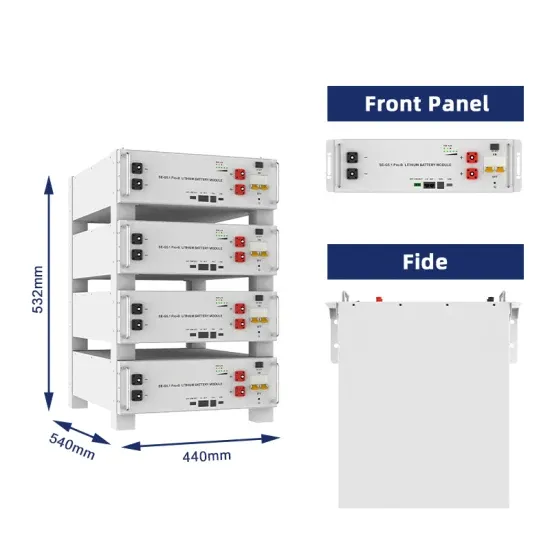

What makes a telecom battery pack compatible with a base station?

Compatibility and Installation Voltage Compatibility: 48V is the standard voltage for telecom base stations, so the battery pack’s output voltage must align with base station equipment requirements. Modular Design: A modular structure simplifies installation, maintenance, and scalability.

Which battery is best for telecom base station backup power?

Among various battery technologies, Lithium Iron Phosphate (LiFePO4) batteries stand out as the ideal choice for telecom base station backup power due to their high safety, long lifespan, and excellent thermal stability.

How do you protect a telecom base station?

Backup power systems in telecom base stations often operate for extended periods, making thermal management critical. Key suggestions include: Cooling System: Install fans or heat sinks inside the battery pack to ensure efficient heat dissipation.

What is a lithium iron phosphate (LiFePO4) battery?

Lithium Iron Phosphate (LiFePO4) batteries are a type of lithium-ion battery with a lithium iron phosphate cathode and typically a graphite anode. Compared to traditional lead-acid batteries or other lithium-ion batteries (such as ternary lithium batteries), LiFePO4 batteries offer several notable advantages:

What makes a good battery management system?

A well-designed BMS should include: Voltage Monitoring: Real-time monitoring of each cell’s voltage to prevent overcharging or over-discharging. Temperature Management: Built-in temperature sensors to monitor the battery pack’s temperature, preventing overheating or operation in extreme cold.

What is a battery management system (BMS)?

Battery Management System (BMS) The Battery Management System (BMS) is the core component of a LiFePO4 battery pack, responsible for monitoring and protecting the battery’s operational status. A well-designed BMS should include: Voltage Monitoring: Real-time monitoring of each cell’s voltage to prevent overcharging or over-discharging.

Update Information

- Dakar emergency communication base station lithium ion battery

- Wellington Communication Base Station Lithium Ion Battery Application

- 5g communication base station lithium ion battery design

- Lithium battery communication base station price

- Lithium battery communication base station configuration

- Is the flow battery room of a communication base station considered equipment

- Nauru communication base station lithium battery energy storage

- Brussels communication base station flow battery construction company

- Battery Agent for Communication Base Station

- Is the battery energy storage system of St George communication base station good

- Battery energy storage system for Saint Lucia communication base station

- Communication base station battery pcb

- Algeria small base station energy storage lithium battery

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.