High Frequency Inverter vs low Frequency Inverter

Conclusion In conclusion, the choice between high-frequency and low-frequency inverters depends largely on the specific needs of the application. High-frequency inverters offer the

Frequency Inverter Basic: Introduction, Functions

Dec 11, 2023 · A frequency inverter is a device that converts industrial frequency power supply (50Hz or 60Hz) into AC power supply of various frequencies to

Performance evaluation of grid-following and grid-forming inverters

Mar 1, 2023 · Performance evaluation of grid-following and grid-forming inverters on frequency stability in low-inertia power systems by power hardware-in-the-loop testing

Inversion Methods Explained: High Frequency vs Low Frequency

4 days ago · LF inverters have larger and more robust Field Effect Transistors (FET''s) that can operate cooler, in part due to the slower frequency of switching required to produce AC power.

What is a power inverter? | Tech | Matsusada

Aug 31, 2021 · Basic Technical Explanation of inverter - Power Inverter circuit and power inverter device, Frequency and Rotation Speed, Device configuration,

Inverter-based resources dominated grid: Voltage and frequency

Jun 1, 2025 · The frequency response is assessed following largest power infeed loss by plants technology (IBR or synchronous generator). The results demonstrate that inverter-dominated

Micro Inverters and Frequency Shift Power Control

Aug 20, 2021 · Folks AFAIK, the micro inverters require a grid or a battery-backup grid to produce power. If grid fails, the micro inverters will shut down even if they have plenty of sun light for

Guide to Frequency Inverters: Optimizing Motor

Nov 13, 2024 · I. Introduction to Frequency Inverters (VFDs) Frequency inverters, also known as variable frequency drives (VFDs), are essential components in

Frequency inverter design

Sep 5, 2018 · Flux vector frequency inverters have the same power section as all PWM frequency inverters, but use a sophisticated closed loop control from the motor to the frequency inverter''s

When Is It Necessary to Use a Reactor with a

2 days ago · It is typically installed either at the input (AC line reactor) or in the DC bus (DC link reactor) of the inverter VFD. Reactors protect sensitive power

Inversion Methods Explained: High Frequency vs Low Frequency

4 days ago · There are two distinct types of industrial grade power inverters distinguished by the size of their transformers, and the switching speed of their transistors. The ability of an inverter

The Differrence Between Frequency Inverter and

Dec 12, 2016 · In this comprehensive guide, we delve into the contrasting features of power inverters and frequency inverters. By exploring their functionalities,

Fast Frequency Response Concepts and Bulk Power System

Mar 31, 2025 · Fast Frequency Response Concepts and Bulk Power System Reliability Needs (NERC 2020) This whitepaper was published in March 2020 by the Inverter-Based Resources

Design and Development of High Frequency Inverter for

Overall, implementing a high-frequency inverter for WPT applications requires careful consideration of several factors, including power requirements, efficiency, and EMI.The

Power Frequency Inverter vs High-Frequency Inverter

Nov 14, 2024 · If you are looking for an inverter for fixed power stations, precision instruments, or other related fields, then go with power-frequency inverters. However, a high-frequency

What is a Frequency Inverter? A Complete Guide to How It

4 days ago · A frequency inverter is an electronic device that converts the fixed frequency and fixed voltage from your electrical supply (e.g.,50Hz or 60Hz,240V or 480V)into a variable

6 FAQs about [Inverter frequency and power]

What is frequency inverter?

Frequency inverter, also named as VFD, is a kind of power control equipment adopting frequency conversion technology and microelectronics technology to control AC motor by changing the motor power frequency.

What is the difference between power inverter and frequency inverters?

The power inverter is a device that can convert DC into AC and the frequency inverter is a component used to change the AC frequency. The power inverter can convert DC power (battery, accumulator jar) into AC power (sinusoidal wave of 220V and 50 Hz), and the frequency can also be adjusted.

How does a power inverter work?

The power inverter can convert DC power (battery, accumulator jar) into AC power (sinusoidal wave of 220V and 50 Hz), and the frequency can also be adjusted. The frequency inverter can convert the input AC into the AC with required frequency and then output it. The work principles include AC-DC-AC or AC-AC.

What are the components of a frequency inverter?

The frequency inverter is mainly composed of rectifier (from AC to DC), filter, inverter (from DC to AC), braking unit, driving unit, detecting unit and micro processing unit, etc. The frequency converter can adjust the output power’s voltage and frequency by controlling the on and off of the IGBT.

How do you connect a motor to a frequency inverter?

Connecting a motor to a frequency inverter is a straightforward process. Typically, the inverter is wired to the motor using three main power lines—one for each phase of the motor. In addition to the power connections, inverters often have terminals for switch inputs, which control the motor’s start/stop functions and direction of rotation.

How do frequency inverters affect motor performance?

A frequency inverter’s primary function is to manage motor performance by adjusting the electrical supply, but the way it does this can vary depending on the method of control used and the motor's specific demands. Here's a breakdown of how frequency inverters influence motor performance:

Update Information

- Bahamas 10kw power frequency isolation inverter

- Boston power frequency inverter power

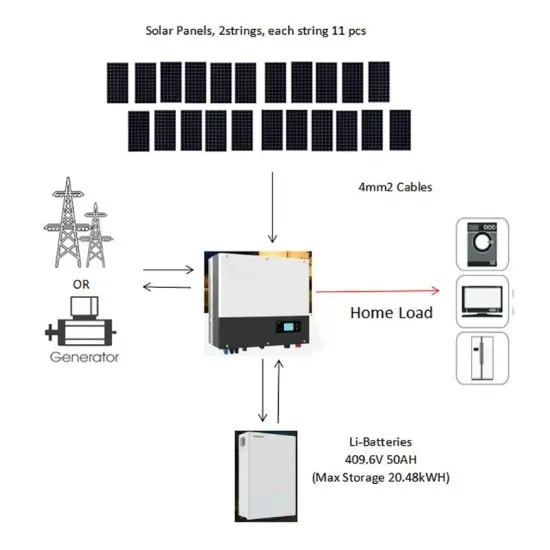

- Power frequency inverter connected to solar energy

- Charging inverter sine wave power frequency inverter

- Power frequency inverter self-grid connection

- Inverter Type High Frequency Power Frequency

- Austria high frequency power inverter

- Wellington power frequency inverter price

- Copenhagen 10kw power frequency isolation inverter

- Democratic Republic of Congo off-grid power frequency 15kw inverter

- Castrie power frequency off-grid inverter price

- Ethiopia 48v power frequency inverter

- Sri Lanka High Frequency Power Inverter

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.