Intelligent Telecom Energy Storage White Paper

Jul 7, 2023 · ion, partial perception, and partial analysis. With a basic BMS, lithium batteries are connected through the power supply system to the EMS that provides basic functions like

Understanding the Role of BMS, EMS, and PCS in Battery

Jan 10, 2025 · Discover the critical roles of BMS, EMS, and PCS in Battery Energy Storage Systems (BESS). Learn how these components ensure safety, efficiency, and reliability in

What is the purpose of batteries at telecom base

Feb 10, 2025 · The lead storage battery is the most widely used energy storage battery in the current communication power supply. Among the many types of

Small Cell Networks and the Evolution of 5G

May 17, 2017 · This is the first blog post in a 2-part series looking at small cell base stations. Part 1 covers the basics of small cells and how they fit into the

Optimization of Communication Base Station Battery

Dec 1, 2023 · Based on the above previous studies, we observe that there are few studies on the impact of uncertain base station interruptions on battery resource allocation decisions, and

Design Considerations and Energy Management System for

Jun 20, 2024 · This paper presents the design considerations and optimization of an energy management system (EMS) tailored for telecommunication base stations (BS) powered by

Design Considerations and Energy Management System for

Jun 20, 2024 · This paper presents the design considerations and optimization of an energy management system (EMS) tailored for telecommunication base stations (BS) powered by

The Evolution of Energy Management Systems in Battery

Sep 5, 2024 · An Energy Management System (EMS) serves as the "brain" of a battery energy storage system (BESS), responsible for monitoring, controlling, and optimizing its operation.

Optimization of Communication Base Station Battery

Dec 7, 2023 · In the communication power supply field, base station interruptions may occur due to sudden natural disasters or unstable power supplies. This work studies the optimization of

6 FAQs about [The EMS battery of the communication base station is too small]

What is a battery management system (EMS)?

It converts electricity between alternating current (AC) and direct current (DC), facilitating the charging and discharging of the battery. Energy Management System (EMS): The EMS is the brain of the operation. It monitors energy flows, decides when to store or release energy, and ensures optimal performance of the entire system.

How do EMS and BMS work together?

The two systems work together: EMS is responsible for the overall optimization of energy, while BMS focuses on the internal management and health monitoring of the battery. In a complete BESS, BMS provides the battery’s operating status information, and EMS uses this data to optimize the entire storage system’s charging and discharging strategy.

How does EMS optimize battery charging and discharging?

Optimization Control: Based on the analysis, EMS automatically adjusts the battery’s charging and discharging status by controlling the operation of various devices, ensuring that the battery operates within safe limits while maximizing economic benefits.

What does EMS stand for?

EMS (Energy Management Systems) Technologies Optimizing Energy Consumption for Mobile phone Base Stations Due to the sharp rise in the number of mobile phone subscribers in India and other emerging countries more and more base stations that support mobile phone networks are being built.

What is BMS & EMS?

In a complete BESS, BMS provides the battery’s operating status information, and EMS uses this data to optimize the entire storage system’s charging and discharging strategy. EMS plays a vital role in energy storage systems.

Why is NEC conducting a demonstration test of EMS technology?

NEC is conducting demonstration test of the EMS (en- ergy management system) technology and aims to re- duce both diesel oil consumption and CO2 emissions. Our solution employs an EMS to control the power systems via use of LIB (lithium-ion batteries), PV (photovoltaic) and DG. 2. The Background of the Demonstration Test

Update Information

- Small residents obstruct communication base station battery

- HJ battery communication small base station market share

- Small communication base station inverter grid-connected battery

- How much power does the battery energy storage system of a building communication base station generally have

- Funafoti communication base station inverter grid-connected battery detection

- Communication base station battery energy storage system signal interruption

- Is there a battery for flywheel energy storage on the roof of a communication base station

- Honduras communication base station hybrid energy battery detection

- What are the power equipment of the communication base station battery energy storage system

- Communication Base Station EMS Budget Company

- Oman 5G communication base station battery energy storage system construction bidding

- Liquid flow battery energy storage for Banjul communication base station

- Algeria small base station energy storage lithium battery

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

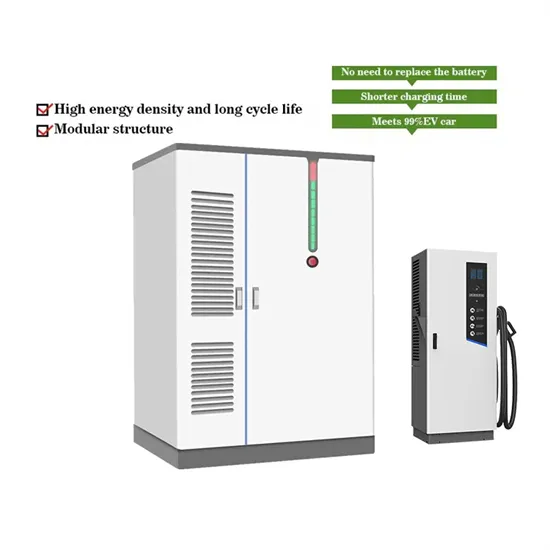

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.